Manufacturing

Rubber, Plastic, and Metal parts can be manufactured using many methods, each suitable for different applications and part complexities. Here are some of the common manufacturing techniques that we offer, some of which may not be available for specific materials.

Each of these methods has its own advantages, limitations, and cost implications. The choice of manufacturing technique usually depends on factors like the complexity of the design, required precision, material properties, and production volume.

Canyon Components strives to meet all customer service requests. Feel free to contact Canyon Components engineering and let our knowledgeable staff help you design the perfect part for your needs.

Manufacturing

Injection Molding

This is a popular method for producing high volumes of plastic or rubber parts. The plastic or rubber is injected in a molten form into a mold cavity where it cools and solidifies into the final shape. It's ideal for making complex shapes with high precision.

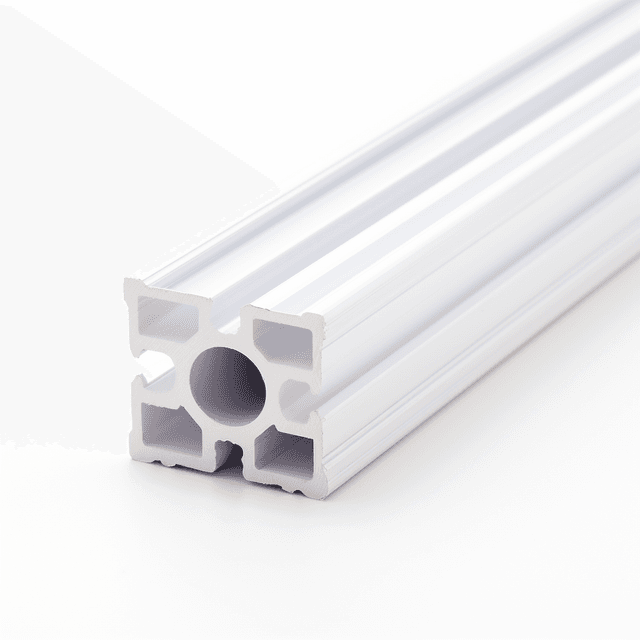

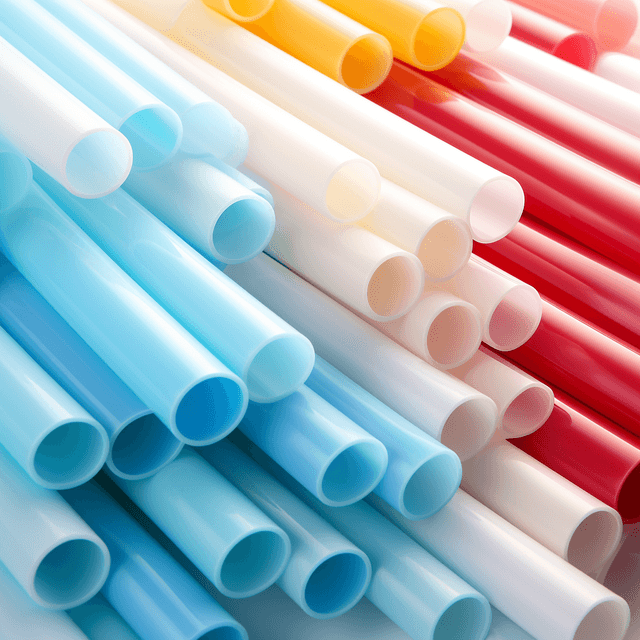

Extrusion

In this process, plastic, metal, or rubber, is forced through a die in a molten form to create long continuous shapes like pipes, tubing, sheets, or profiles. The extruded material is then cut to the desired length. It's excellent for producing products with a constant cross-sectional profile.

Thermoforming

In this process, a sheet of plastic is heated to a pliable forming temperature, formed to a specific shape in a mold, and trimmed to create a usable product. It's commonly used for packaging and larger parts like automotive door panels.

Micro-Extrusion

A specialized form of extrusion used to produce extremely small and precise plastic, metal, or rubber parts. It's ideal for medical devices and intricate components.

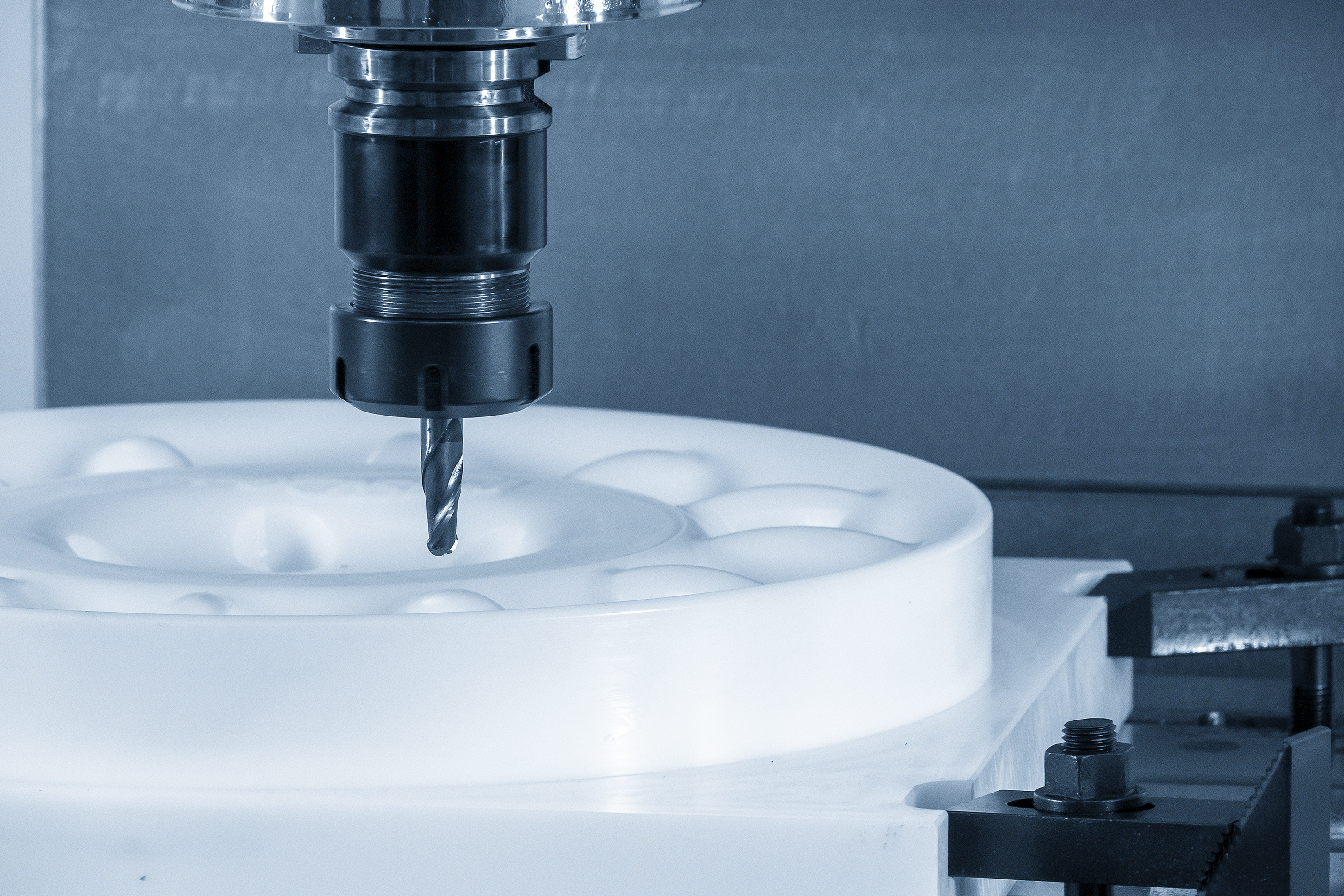

CNC Machining

This subtractive method involves starting with a solid block of plastic, metal, or rubber, and then cutting away material to create the desired shape. It's useful for prototypes and low-volume production of parts with high precision.

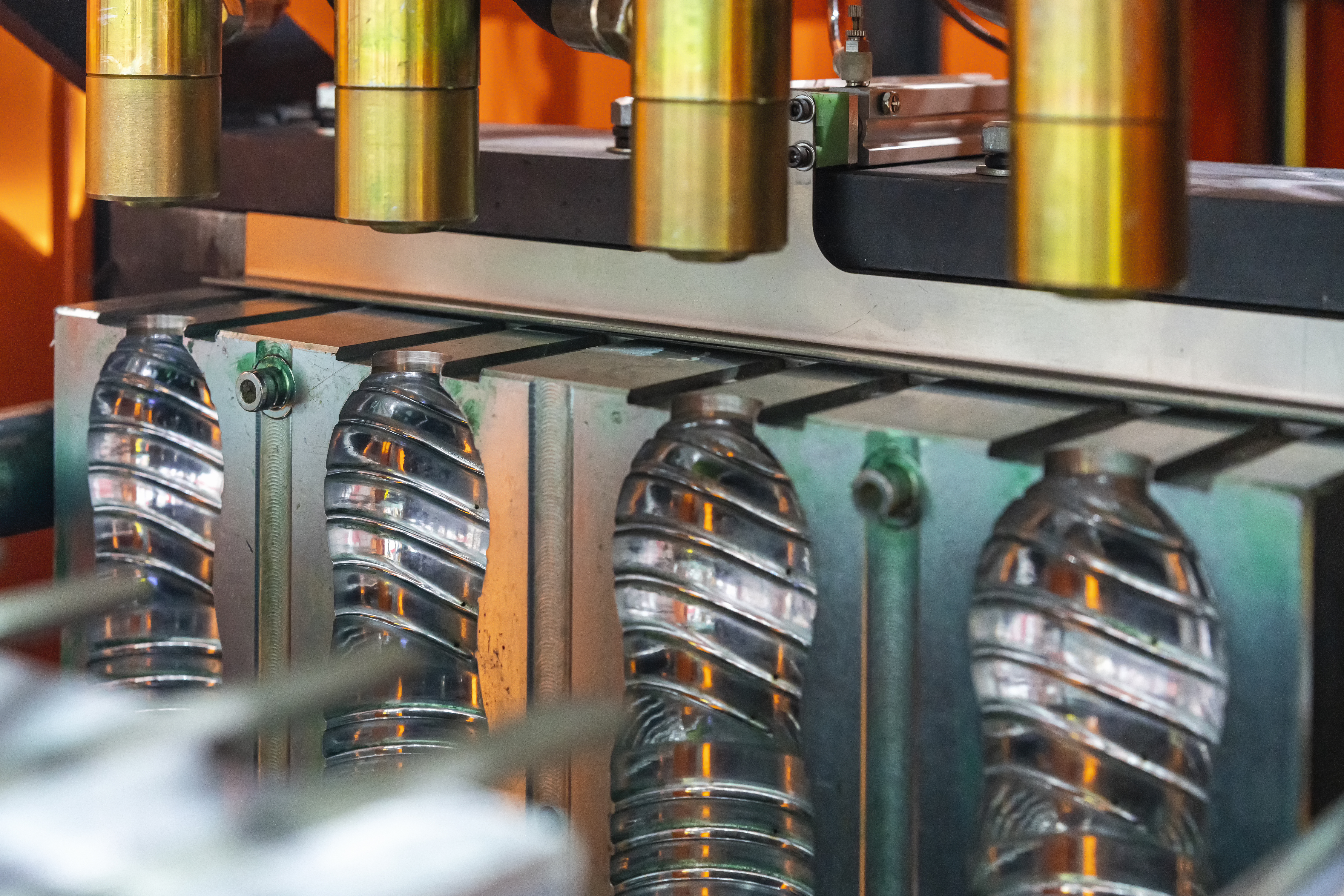

Blow Molding

This method is used to create hollow plastic parts such as bottles and containers. The plastic is melted and formed into a parison, which is then clamped into a mold. Air is blown into the parison, inflating it into the shape of the mold cavity.

Rotational Molding (Rotomolding)

Suitable for creating large, hollow parts. Plastic powder is placed inside a mold, which is then heated and rotated along two perpendicular axes. The plastic melts and coats the inside of the mold, forming the desired shape upon cooling.

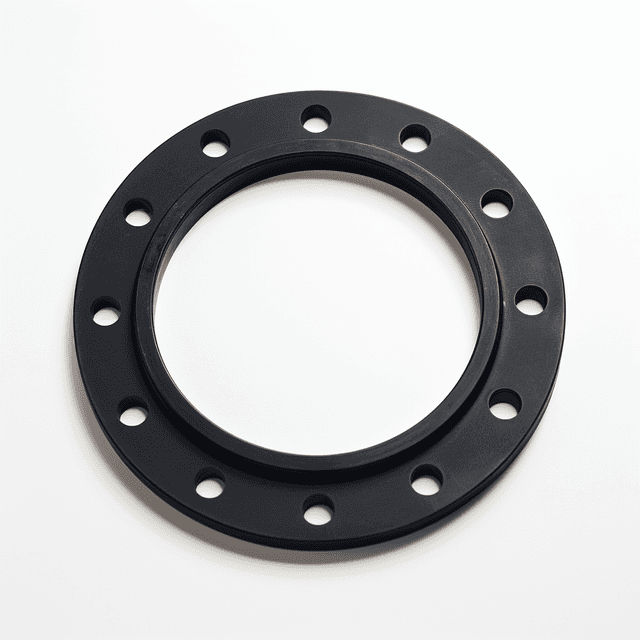

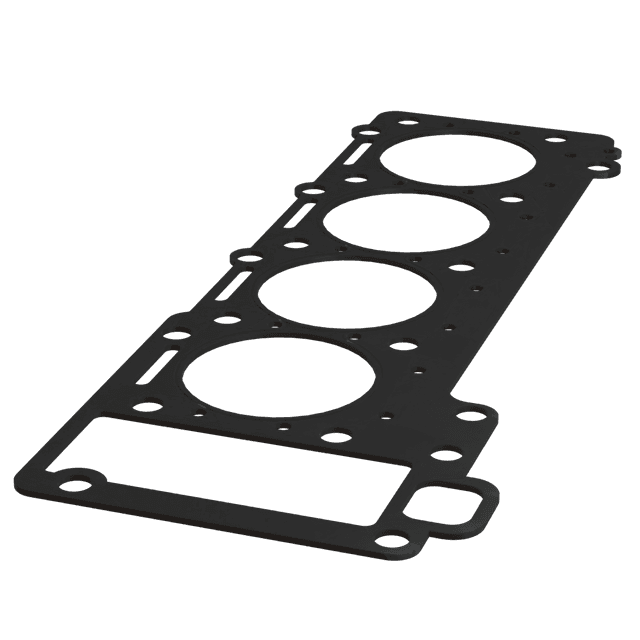

Compression Molding

Plastic or rubber is placed in a heated mold cavity and then compressed to form a specific shape. This method is less common for many plastics, but can be used for large, fairly simple parts.

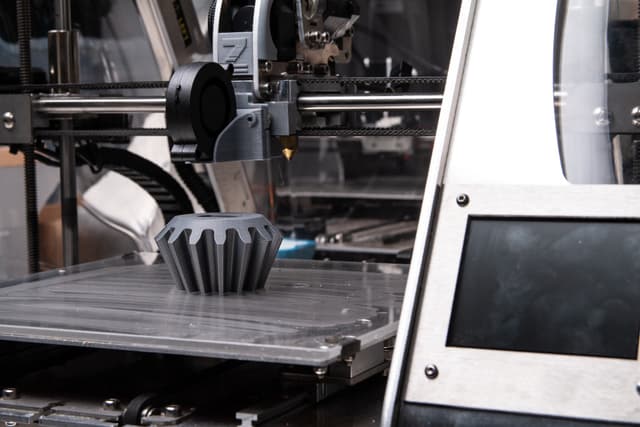

3D Printing (Additive Manufacturing)

3D printing can be used to produce complex geometries and bespoke parts. Specialized printers and filament types can be required when producing certain types of plastic, rubber, or metal.

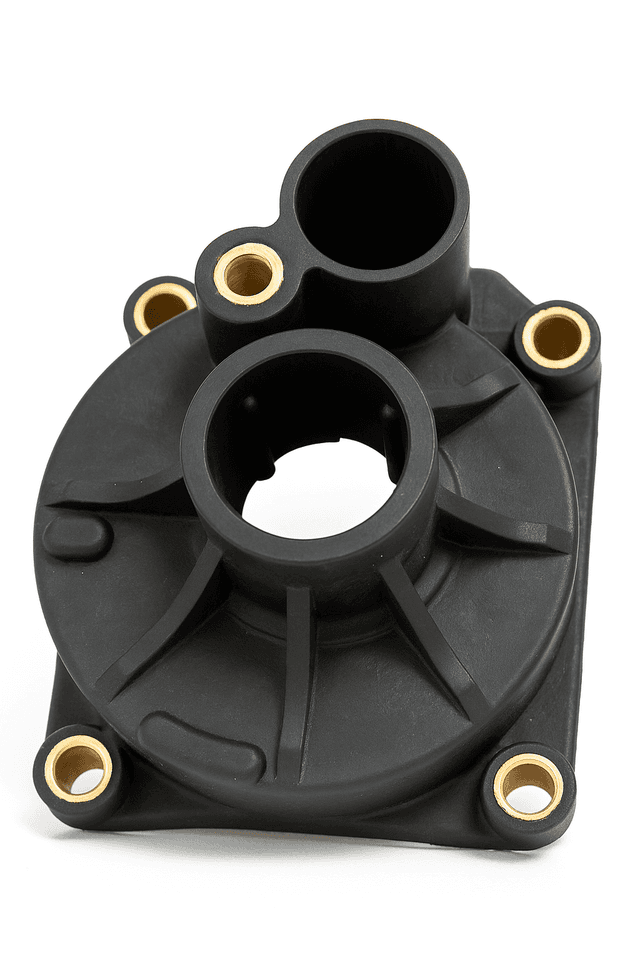

Overmolding

This is a multistage process where a finished plastic, metal, or rubber part is inserted into a mold and another plastic or rubber is molded over it to create a composite part. It's used to add soft-touch surfaces or to combine rigid and flexible elements in a single component.

Casting

Involves pouring liquid plastic, rubber, or metal into a mold where it solidifies. This method is typically used for creating large, simple shapes or when a very smooth surface finish is required. It's less precise than injection molding but can be more cost-effective for small production runs or larger items. It can also be used for forming molten metal.

Cutting

Cutting manufacturing encompasses a range of processes that involve separating materials into desired shapes or sizes by removing excess material. It plays a crucial role in various industries, offering precision, speed, and versatility.

Back to Products Hub

Get A Quote Now!

Groove Design References

Learn More

Coatings, Packaging, & Other Services

Learn More

Custom Parts & Custom O-rings

Learn More

FAQ

Modern manufacturing combines precision, adaptability, and material science to produce components that perform flawlessly in demanding environments. Whether the goal is to mold a high-temperature FFKM O-ring, machine a tight-tolerance PEEK component, or fabricate a stainless-steel assembly, success depends on the right mix of technology, expertise, and quality control. Canyon Components’ Manufacturing Hub brings all of these capabilities together, offering custom injection molding, CNC machining, and advanced fabrication for elastomers, plastics, and metals. Our engineering team works closely with customers from concept to completion, ensuring each part meets both functional and compliance standards across industries like aerospace, chemical processing, and medical technology.

What is CNC machining, and when is it preferred over molding?

CNC machining is ideal for applications that require extreme precision or smaller production quantities. It involves subtractive manufacturing, where advanced machines cut or shape parts from solid blocks of metal or plastic. Canyon Components utilizes multi-axis CNC machines capable of maintaining tolerances within thousandths of an inch. This method is preferred for prototype development, tight-tolerance plastic components like PEEK and PTFE, and metal fittings or housings that must meet stringent dimensional requirements. CNC machining also allows for rapid adjustments and low setup times, making it ideal for custom or specialty parts. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What materials can be used in Canyon Components’ manufacturing processes?

A wide range of materials can be processed, including elastomers (FFKM, FKM, EPDM, NBR, silicone), engineering plastics (PTFE, PEEK, Acetal, Nylon, UHMW), and metals (stainless steel, aluminum, brass, titanium). Each material offers specific mechanical and chemical advantages. Canyon Components evaluates your operating environment to recommend the best compound or alloy for performance and longevity. Whether you need flexibility and sealing from elastomers, precision from plastics, or structural strength from metals, our multi-material manufacturing capability ensures a perfect fit for each project. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

How does fabrication differ from machining and molding?

Fabrication typically refers to the assembly or forming of materials rather than their direct shaping or cutting. This can include processes like welding, forming, stamping, or combining multiple components into a single assembly. Canyon Components’ fabrication services integrate metals, plastics, and elastomers to produce complete systems such as bonded seals, reinforced diaphragms, or bracketed assemblies. Fabrication bridges the gap between individual part production and full assembly, allowing us to deliver parts that arrive ready for installation. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

How does Canyon Components ensure tight tolerances and quality consistency?

Precision and repeatability are achieved through a combination of advanced equipment and rigorous quality control. Canyon Components employs coordinate measuring machines (CMM), laser inspection, and surface analysis tools to verify dimensions and finish. Statistical process control and continuous monitoring ensure consistency across production batches. For industries requiring certification, such as aerospace and medical, we maintain documentation for material traceability and inspection reports that confirm compliance with customer specifications and regulatory standards. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

Can Canyon Components create prototypes before full production?

Yes. Prototyping allows for functional testing and design validation before committing to tooling or large-scale manufacturing. Canyon Components offers rapid prototyping through CNC machining, 3D printing, and short-run molding, helping customers refine geometry, tolerances, and material selection. This service reduces design risk, ensures compatibility with mating components, and often shortens the overall development timeline by identifying potential issues early in the process. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What secondary operations are available after molding or machining?

Many components require post-processing to meet specific performance or cosmetic goals. Canyon Components provides deflashing, polishing, coating, bonding, drilling, and assembly services, along with surface finishing like anodizing or passivation for metal parts. For elastomers, we can apply plasma coatings, internal or external lubricants, and parylene films to improve chemical resistance or reduce friction. These finishing steps ensure that every part performs optimally and maintains its integrity throughout its service life. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

How does Canyon Components handle complex or multi-material assemblies?

Some applications require parts that combine multiple materials for unique mechanical or chemical properties. Canyon Components specializes in metal-to-rubber bonding, plastic-overmolding, and hybrid assembly manufacturing, allowing engineers to integrate flexibility, insulation, and strength into one component. These processes are used in dynamic seals, vibration mounts, and valves where performance and precision are both critical. By controlling each step of the process, we ensure complete alignment between design intent and final functionality. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

Are Canyon Components’ manufacturing processes compliant with industry standards?

Yes. We manufacture to meet or exceed major standards such as ASTM, ISO 9001, FDA, USP Class VI, and MIL/AMS specifications, depending on the material and application. Aerospace and medical customers often require detailed validation, and our team provides full documentation packages, including material certifications, inspection records, and traceability reports. Compliance is built into every stage of production, ensuring consistent quality and reliability. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What are the advantages of working with a single-source manufacturer?

Partnering with a company that can handle multiple materials and processes simplifies logistics, improves communication, and shortens lead times. Canyon Components provides a fully integrated approach, managing every step from design consultation to finished part delivery. This means fewer suppliers to coordinate, reduced risk of error, and better control over quality and timelines. Customers benefit from a streamlined process that ensures every component, whether molded, machined, or fabricated, is engineered and built to perform. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

How does Canyon Components support design optimization and long-term reliability?

Manufacturing is most effective when design and engineering work hand in hand. Canyon Components offers design for manufacturability support, where our engineers review geometry, tolerances, and material choices to optimize performance and production efficiency. We also provide ongoing consultation for customers seeking to improve existing designs or extend product life. By combining material expertise, precision tooling, and iterative feedback, we help ensure that every component delivers dependable performance throughout its operational lifespan. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!