AS568 O-rings and O-ring Groove Design Guide

Updated: Jul 26, 2024

Introduction to AS568 O-Rings

O-rings are critical components in many mechanical systems, providing essential sealing functions in a wide range of applications. Among the various standards for O-rings, AS568 is one of the most commonly used in the United States. This guide will delve into the world of AS568 O-rings, exploring their features, applications, and why they're a popular choice in various industries.

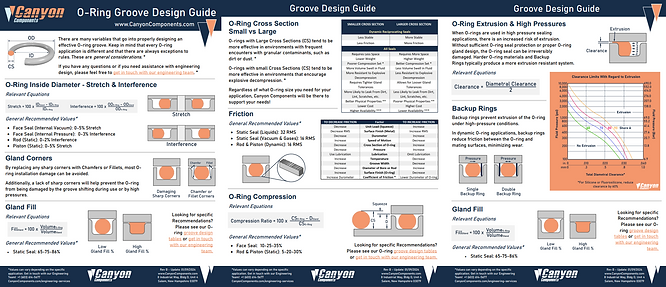

O-Ring Groove Design Guide and AS568 Tables

See Canyon Components' new O-ring Groove Design Guide and AS568 Tables here! This comprehensive guide will aid you in not only choosing the right O-ring for your application, but also in properly designing O-ring grooves to help prevent unnecessary damage and premature O-ring failure.

What Are AS568 O-Rings?

AS568 O-rings are made to the specifications set by the Aerospace Material Specification (AMS). This standard defines the O-ring's size, tolerance, and sometimes material composition. They are typically made from elastomeric materials like Nitrile, Silicone, Fluorocarbon (Viton), and Ethylene Propylene Diene Monomer (EPDM).

Key Features

- Standardized Sizes: AS568 specifies exact dimensions for O-rings, ensuring consistency and compatibility across different applications.

- Material Versatility: Available in various materials to suit different environmental conditions and chemical exposures.

- Temperature Resistance: Capable of operating in a wide temperature range, depending on the material used.

- Durability: Designed to withstand pressure variations and mechanical stress.

Applications of AS568 O-Rings

AS568 O-rings are used in a myriad of applications, including:

- Aerospace and Aviation: For sealing fuel systems, hydraulic lines, and air conditioning units.

- Automotive Industry: In engines, transmissions, and fuel handling systems.

- Oil and Gas Sector: For high-pressure and high-temperature environments.

- Medical Devices: In equipment that requires sterilization and biocompatibility.

- General Industrial Use: In pumps, valves, and fluid transfer systems.

Choosing the Right AS568 O-Ring

Selecting the correct O-ring involves considering:

- Size and Fit: Ensuring the O-ring matches the groove dimensions precisely.

- Material Suitability: Depending on chemical exposure and temperature range.

- Compliance with Standards: Verifying that the O-ring meets specific industry requirements.

Maintenance and Replacement

Proper maintenance is crucial for AS568 O-rings:

- Regular Inspection: Checking for wear, tear, and deformation.

- Environmental Factors: Being aware of changes in temperature or chemical exposure.

- Replacement: Timely replacement is essential to prevent failures.

Conclusion

AS568 O-rings are a cornerstone in the world of seals, offering reliability and standardization. Their wide range of applications and ability to withstand various environmental conditions make them indispensable in numerous industries. Understanding their properties, applications, and maintenance requirements can significantly contribute to the efficiency and safety of mechanical systems.

Whether you're in aerospace, automotive, or any other industry requiring robust sealing solutions, AS568 O-rings are likely to be part of your toolkit. Remember, the right O-ring not only seals perfectly but also enhances the longevity and performance of your equipment. See Canyon Components' new O-ring Groove Design Guide and AS568 Tables here for a comprehensive quick reference guide!