Medical Grade USP Class VI EPDM (Ethylene Propylene) Selection Guide

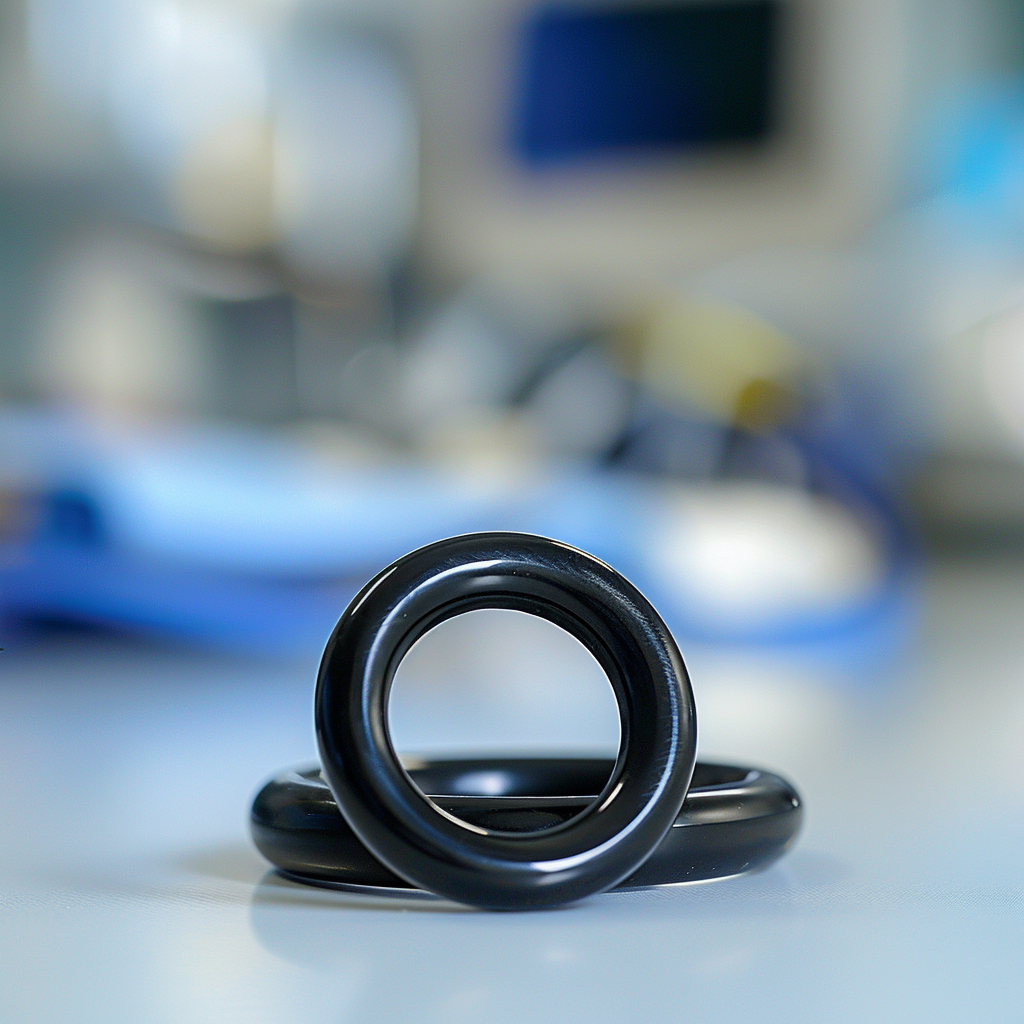

USP Class VI EPDM (Ethylene Propylene Diene Monomer) is a high-purity elastomer certified to meet the rigorous standards set by the United States Pharmacopeia (USP) for biocompatibility and safety in pharmaceutical applications. This specialized EPDM is designed for use in environments where it will come into direct or indirect contact with pharmaceutical products and/or used in medical devices. This webpage explores the different types of USP Class VI EPDM, their advantages and disadvantages, and their wide range of industrial applications, emphasizing the production of O-rings, gaskets, and custom parts.

The engineers and consultants here at Canyon Components take pride in finding the perfect seal to suit our customer’s needs. Contact our expert staff for assistance with any seal or application questions!

Common names include: EPDM (Ethylene-propylene diene monomer), EP Trade Names: Nordel®, Epcar®, Epsyn®, Vistalon®, Royalene®, Vistalon®

Request a Quote for Medical Grade USP Class VI EPDM

Features of USP Class VI EPDM

- Biocompatibility: Certified to meet USP Class VI standards, ensuring that O-rings, gaskets, and custom parts do not adversely affect human health when used in pharmaceutical products.

- Chemical Resistance: Medical grade USP Class VI EPDM is resistant to many chemicals and pharmaceutical agents, providing reliable performance in diverse processing environments.

- Thermal Stability: Medical grade USP Class VI EPDM maintains its properties over a broad temperature range, which is critical for processes involving sterilization and high-temperature cleaning.

- Elasticity and Durability: Medical grade USP Class VI EPDM maintains excellent elasticity and resilience, ensuring effective and long-lasting seals in dynamic and static applications.

Limitations of USP Class VI EPDM

- Cost: The certification and advanced properties of USP Class VI EPDM make it more expensive than standard EPDM materials.

- Limited Oil Resistance: Like standard EPDM, it does not perform well with petroleum-based oils and fats, which can be a drawback in some industrial applications.

- Specialized Use: As it is specifically designed for pharmaceutical applications, its use may be overly specialized for more general industrial applications.

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

USP Class VI EPDM Materials Available

This table shows many of our standard materials and links out to our O-ring store. Get in touch with us if you need a custom gasket, custom molded part, or non-standard geometry!

Filter by

Temperature Search (°C)

Industrial Usage of USP Class VI EPDM

USP Class VI EPDM is an indispensable material in the pharmaceutical, biotech, and related industries, trusted for its safety, reliability, and performance. By enabling the manufacture of safe and effective O-rings, gaskets, and custom parts, USP Class VI EPDM plays a crucial role in maintaining the integrity and cleanliness of pharmaceutical processes. Despite its higher cost and specific application range, the benefits of USP Class VI EPDM in critical health-related applications make it a valuable choice for manufacturers prioritizing product safety and compliance.

Canyon Components strives to meet all customer service requests. Feel free to contact Canyon Components engineering and let our knowledgeable staff help you design the perfect part for your needs.

Pharmaceutical Manufacturing

Widely used for O-rings, gaskets, and custom parts in processing equipment, including mixers, pumps, and valves, where non-toxic and inert materials are crucial.

Biotechnology

Essential in bioreactors and fermentation tanks, where it is critical that the materials do not introduce contaminants or react with biological agents.

Medical Devices

Used in devices that require repeated sterilization, such as in dialyzers and surgical tools, providing safe and reliable performance.

Food and Beverage Processing

Although primarily for pharmaceuticals, its safety profile makes it suitable for food-grade applications requiring high-purity materials.

Cosmetics Industry

Utilized in the production of containers and seals within the cosmetics industry, where purity and safety are also highly valued.

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

Back to Elastomers Hub

Get A Quote Now!

Groove Design References

Learn More

Coatings, Packaging, & Other Services

Learn More

Custom Parts & Custom O-rings

Learn More