Chemical Processing O-ring Materials

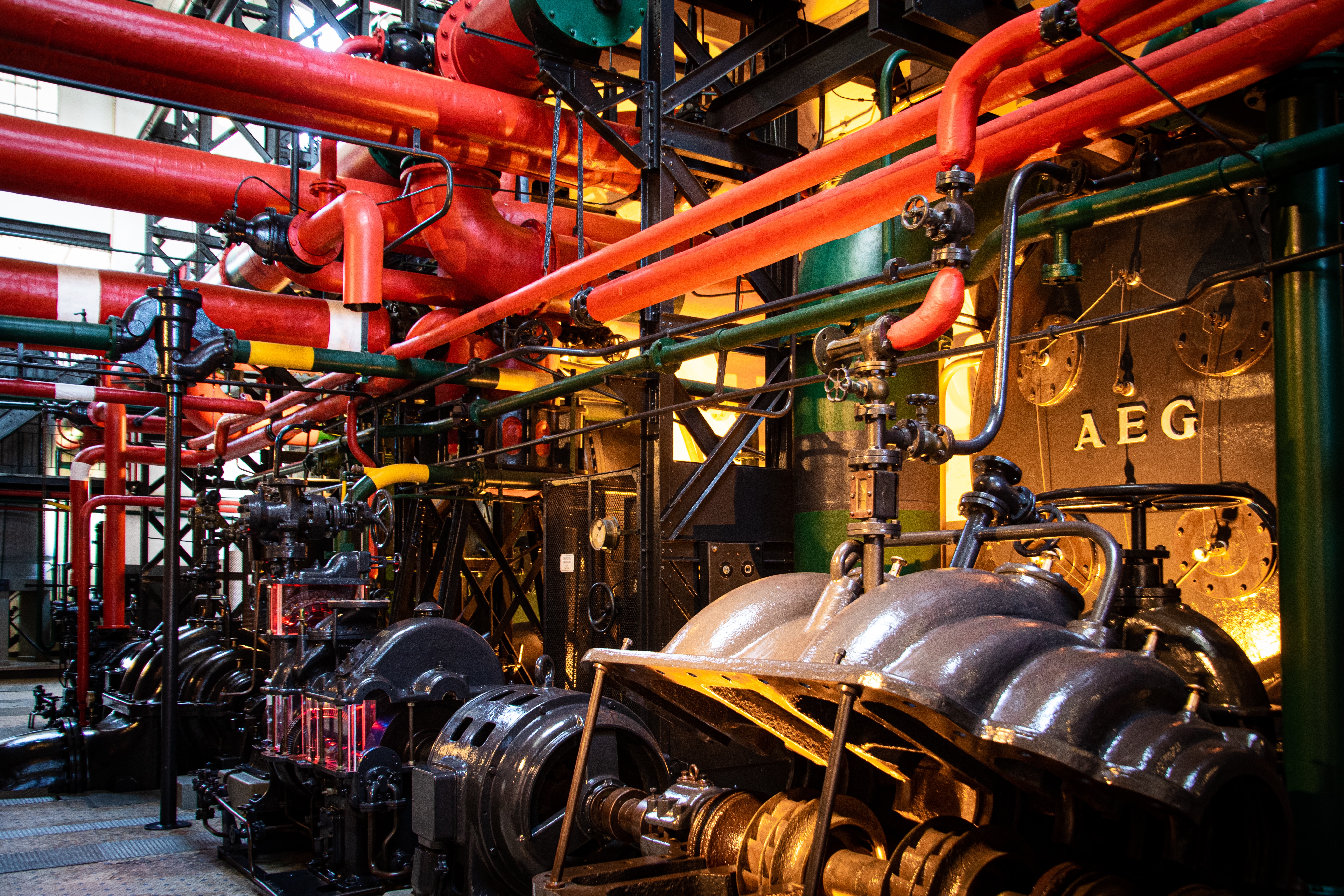

The chemical processing industry relies on materials that can withstand aggressive chemical environments, high temperatures, and extreme pressures. Chemical processing grade materials are specifically designed and manufactured to meet these rigorous demands, ensuring safety, reliability, and efficiency. In this web page, we will explore the significance of chemical processing grade materials, common application considerations, and discuss different types used in the industry.

With Canyon Components, you can be sure that high quality materials that meet you needs are always readily available. Custom & standard Chemical Processing Materials available now!

Check with one of Canyon’s helpful product engineers for an expert material and manufacturing recommendation.

Chemical Processing Materials Available

Thousands of Chemical Processing Materials are available now with Canyon Components! Some common Chemical Processing Materials include the following.

This table shows many of our standard materials and links out to our O-ring store. Get in touch with us if you need a custom gasket, custom molded part, or non-standard geometry!

Filter by

Temperature Search (°C)

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

What are Chemical Processing Grade Materials?

- Chemical processing grade materials are substances, components, or equipment engineered to excel in the challenging conditions of the chemical processing industry. These materials must exhibit high chemical resistance, thermal stability, and mechanical strength to prevent equipment failure and protect personnel.

Common Considerations

- Chemical Resistance: Materials must be highly resistant to the specific chemicals used in the processing, preventing degradation and corrosion.

- Temperature and Pressure: Materials should withstand the extreme temperatures and pressures encountered in chemical reactors, pipelines, and storage tanks.

- Compatibility: Compatibility with the chemicals, processes, and equipment used in the facility is essential to avoid adverse reactions and maintain product quality.

- Durability: Materials must be durable and capable of withstanding the harsh conditions over an extended service life, reducing maintenance and replacement costs.

- Regulatory Compliance: Compliance with industry standards and regulations is necessary to ensure safety and regulatory approval.

- Cost Efficiency: While performance is crucial, cost considerations should be balanced to optimize material selection.

Material Options

- Perfluoroelastomers (FFKM): Perfluoroelastomers, like Kalrez® and CanRez™, are formulated to perform exceptionally well in almost all abrasive chemicals at extreme temperature ranges. When it comes to chemically resistant and high temperature elastomers, perfluoroelastomers are the best.

- Fluoroelastomers (FKM, Viton): FKM compounds, O-rings, gaskets, & custom molded parts exhibit excellent mechanical attributes as well as excellent resistance to high temperatures, mineral oil, ozone, fuels, hydraulic fluids, and many other solvents and chemicals.

- Fluoropolymers: Fluoropolymer materials like PTFE and PVDF are excellent choices for spring energized seals, backup rings, lining equipment, tanks, and pipes, as they provide high chemical resistance.

- Stainless Steel Alloys: Stainless steel alloys, such as 316L and 317L, are known for their corrosion resistance and are widely used in pipelines, reactors, and storage tanks.

- Corrosion-Resistant Alloys: Specialized alloys like Hastelloy, Inconel, and Monel offer superior resistance to a wide range of corrosive chemicals and are used in critical applications.

- Glass-Lined Steel: Glass-lined steel vessels offer a combination of steel's structural strength and glass's chemical resistance, making them suitable for a variety of chemical processes.

- Ceramic Materials: Ceramic materials, such as alumina and zirconia, are used for their high-temperature resistance and excellent corrosion resistance in specialized applications.

- Plastic Piping: Plastic piping systems made of materials like PVC, CPVC, and PP offer corrosion resistance and are used in chemical transfer and distribution.

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

Chemical Processing

Chemical Compatibility Table

The successful implementation and performance of O-rings, gaskets, and custom molded parts heavily depend on the material compatibility of the components.

Chemical Processing Materials Available

Click here to see some of our most commonly served industries!

Each of these materials has its own advantages, limitations, and cost implications. The choice of material usually depends on factors like chemical compatibility, temperature, pressure, dynamic or static use, and specification requirements.

Canyon Components strives to meet all customer service requests. Feel free to contact Canyon Components engineering and let our knowledgeable staff help you design the perfect part for your needs.

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

Back to Industries Hub

Get A Quote Now!

Groove Design References

Learn More

Coatings, Packaging, & Other Services

Learn More

Custom Parts & Custom O-rings

Learn More

FAQ

Chemical processing environments are among the most demanding for sealing components. Equipment operates under extreme pressure, temperature, and chemical exposure, often involving corrosive fluids that can degrade ordinary materials. Every gasket, O-ring, and custom seal must deliver long-term reliability to prevent leaks, contamination, and costly downtime. Canyon Components provides high-performance sealing materials and designs engineered specifically for these harsh environments. Our Kalrez®, Canrez®, Chemraz®, and Parker® O-rings and gaskets are available in FFKM, FKM, fluorosilicone, EPDM, silicone, and other advanced compounds that withstand the full range of aggressive acids, bases, amines, and solvents found in refineries, reactors, and chemical transport systems. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What are the most common causes of seal failure in chemical applications?

Most failures in chemical processing seals occur due to chemical incompatibility, thermal degradation, compression set, and extrusion damage. Incompatible materials can absorb chemicals, swell, or lose their mechanical properties, while thermal cycling leads to hardening or cracking. Improper gland design or excessive pressure can cause extrusion, tearing, or permanent deformation. Canyon Components prevents these issues by providing materials that meet specific chemical and thermal compatibility standards. We also assist customers with seal groove design optimization, ensuring uniform compression and avoiding overloading or under-filling of glands. Every seal is engineered to handle both static and dynamic stresses in high-pressure and high-temperature chemical systems. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

Which Canyon Components materials are best suited for aggressive chemical environments?

Our most chemically resistant materials include FFKM compounds such as Canrez®, Kalrez®, and Chemraz®, which perform reliably in contact with virtually all process media including concentrated acids, caustics, hydrocarbons, and halogenated solvents. These materials are ideal for critical systems such as pumps, mechanical seals, and high-purity reactors. FKM (fluorocarbon) compounds are suitable for less extreme environments that involve hydrocarbons, oils, or mild acids, offering an economical balance between resistance and flexibility. EPDM provides excellent resistance to steam, hot water, and polar chemicals, while silicone performs well under extreme temperature variations. Canyon Components also offers Aflas® and HNBR compounds for applications requiring amine or sour gas resistance, extending service life under particularly aggressive chemical conditions. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

How do Canyon Components’ materials perform in high-temperature chemical processes?

High temperatures accelerate chemical attack and oxidation, especially in systems with strong acids or oxidizers. Many elastomers lose their elasticity or break down when exposed to continuous heat. Certain blends of Canyon Components’ Canrez FFKM materials are specifically designed for thermal stability over to 600°F while maintaining low compression set and excellent resilience. These materials maintain sealing properties through repeated thermal cycling, which is critical for processes such as polymerization, distillation, and acid production. For lower temperature requirements, our FKM and silicone compounds provide a balance of heat resistance and flexibility. By matching the compound to the temperature profile of the process, Canyon Components ensures consistent sealing force and extended maintenance intervals. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

Can Canyon Components’ seals resist chemical mixtures and solvents?

Yes. Many chemical plants use complex mixtures of solvents, acids, and cleaning agents that challenge traditional seal materials. Canyon Components offers multi-resistant elastomers that retain stability in mixed chemical environments without volume swell or property loss. Our FFKM compounds resist both polar and nonpolar solvents, including acetone, MEK, toluene, and concentrated acids such as nitric or sulfuric. In addition, our FKM and EPDM materials are tested for compatibility with a wide range of cleaning and sterilizing agents, making them suitable for multi-purpose systems. Most compounds undergo chemical immersion testing to verify performance under extended exposure to mixed media. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

How does Canyon Components ensure purity and prevent contamination?

Purity is critical in chemical and pharmaceutical production, where even microscopic contamination can compromise a batch or corrode metal surfaces. Canyon Components manufactures and packages its high-purity materials in controlled environments to prevent contamination by oils, mold release agents, or particulates. We also provide plasma-cleaned, parylene-coated, or PTFE-coated seals to minimize surface reactivity and friction. These coatings reduce sticking, ease installation, and prevent material transfer in reactive environments. For high-purity chemical or semiconductor-grade applications, seals can be cleanroom-packaged and vacuum-sealed, ensuring that they arrive ready for immediate integration into clean systems. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What design considerations improve sealing reliability in chemical processing?

Designing for reliability requires careful attention to gland geometry, compression ratio, and surface finish. Over-compression can lead to early seal failure, while insufficient compression can cause leakage. Canyon Components provides design consultation to help customers optimize groove dimensions, sealing pressure, and material hardness for each application. We also offer back-up rings and anti-extrusion devices for high-pressure systems to maintain seal shape under load. Our engineering team can evaluate your operating environment to recommend the most effective configuration for both static and dynamic seals, reducing downtime and maintenance costs over the equipment’s lifespan. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

Can Canyon Components provide custom-molded parts for chemical systems?

Yes. Many chemical processing systems require seals or components with non-standard dimensions or profiles to fit unique assemblies. Canyon Components manufactures custom-molded O-rings, diaphragms, gaskets, and bonded assemblies in chemically resistant materials. Our production capabilities include compression, injection, and transfer molding, allowing us to achieve precise tolerances for both small prototypes and large production runs. We also produce metal-to-elastomer bonded components and multi-material assemblies for valves, pumps, and mixers, combining the chemical resistance of elastomers with the strength of metals or thermoplastics. All custom parts are validated through dimensional inspection and material testing to ensure long-term reliability. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

Do Canyon Components’ seals comply with industry and safety standards?

Absolutely. Our sealing materials and compounds meet or exceed key industry standards including ASTM D2000, ISO 3601, NACE TM0297, NORSOK M-710, FDA CFR 21.177.2600, and UL 157. We provide full Certificates of Conformance, material test reports, and batch traceability for every shipment. For systems that require clean or sanitary operation, Canyon Components also supplies USP Class VI and FDA-compliant materials that are safe for contact with food or pharmaceuticals. Every product is backed by our in-house quality assurance process, ensuring full compliance and traceable verification of both physical and chemical properties. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What makes Canyon Components a trusted partner for chemical processing companies?

Canyon Components combines material science, precision manufacturing, and responsive engineering support to create sealing solutions that excel under the harshest chemical conditions. We help customers extend equipment life, reduce maintenance costs, and maintain process integrity by selecting the ideal compound for each system. Our experience spans refining, petrochemical, polymer, and specialty chemical manufacturing, giving us the expertise to address complex challenges across the entire process spectrum. Whether you need perfluoroelastomer seals for reactors, PTFE-coated gaskets for piping, or custom assemblies for corrosive environments, Canyon Components delivers certified, high-performance solutions built for durability, safety, and long-term operational success. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!