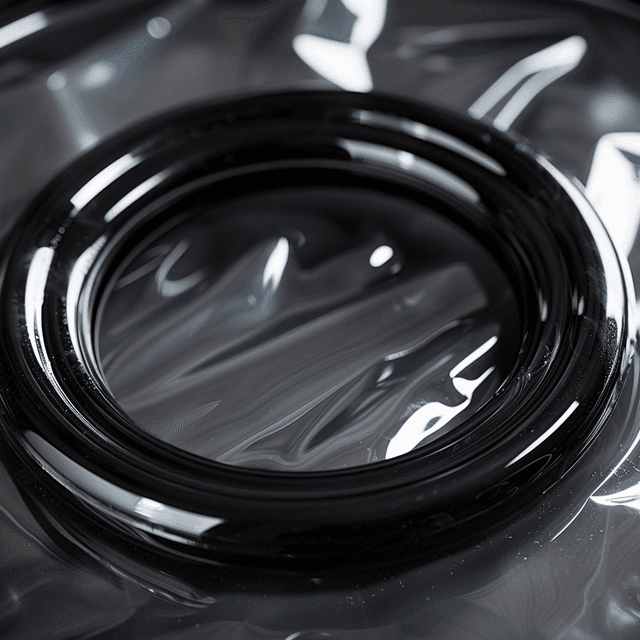

General Purpose O-ring Materials

General purpose materials are versatile and widely used in manufacturing due to their diverse properties and applications. This web page explores common application considerations and the different types of general-purpose materials available now.

With Canyon Components, you can be sure that high quality materials that meet you needs are always readily available. Custom & standard General Purpose Materials available now!

Check with one of Canyon’s helpful product engineers for an expert material and manufacturing recommendation.

General Purpose Materials Available

Thousands of General Purpose Materials are available now with Canyon Components! Some common General Purpose Materials include the following.

This table shows many of our standard materials and links out to our O-ring store. Get in touch with us if you need a custom gasket, custom molded part, or non-standard geometry!

Filter by

Temperature Search (°C)

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

What are General Purpose Materials?

- General-purpose materials are substances or components designed to meet a broad spectrum of needs. These materials are valued for their adaptability, durability, and versatility. They are used in various industries and applications, from automotive to consumer goods.

Common Considerations

- Compatibility: Materials should be compatible with the intended application and environment, including factors like temperature, chemicals, and exposure to UV radiation.

- Strength and Durability: Assess the material's strength and durability to ensure it can withstand the expected loads, stresses, and wear over time.

- Cost Efficiency: Consider the cost of the material and its availability, balancing performance with budget constraints.

- Environmental Impact: Evaluate the environmental impact of the material, including its recyclability and sustainability.

- Manufacturing Process: Ensure that the chosen material is suitable for the manufacturing process and techniques you intend to use.

- Regulatory Compliance: Check if the material meets relevant safety and industry-specific standards and regulations.

Types

- Elastomers: Elastomers are materials that exhibit elasticity and flexibility. They return to their original shape after being stretched or compressed. Common elastomers include:

- FFKM Perfluoroelastomers: The CanRez™ line of perfluoroelastomer (FFKM) materials are at the leading edge of polymer technology. Proven in the field year after year, CanRez™ materials have been developed to offer superior sealing solutions with enhanced high temperature performance and fantastic chemical resistance.

- FKM (Viton): FKM compounds, O-rings, gaskets, & custom molded parts exhibit excellent mechanical attributes as well as excellent resistance to high temperatures, mineral oil, ozone, fuels, hydraulic fluids, and many other solvents and chemicals.

- Silicone: Silicone elastomers are known for their heat resistance and biocompatibility, making them suitable for medical devices, cookware, and automotive components.

- Plastics: Plastics are lightweight & versatile materials with a wide range of applications. Some common plastic types are:

- Polyethylene (PE): Used in custom parts, packaging materials, containers, and pipes.

- Polypropylene (PP): Known for its resistance to heat and chemicals, PP is used in automotive parts, medical devices, and consumer goods.

- Polyvinyl Chloride (PVC): PVC is widely used in construction materials, electrical insulation, and piping.

- Metals: Metals are strong and durable materials often used in structural and mechanical applications. Some common metals include:

- Steel: Steel alloys, such as stainless steel, carbon steel, and alloy steel, are used in construction, automotive manufacturing, and industrial equipment.

- Aluminum: Lightweight and corrosion-resistant, aluminum is used in aerospace, automotive, and packaging industries.

- Copper: Known for its excellent conductivity, copper is used in electrical wiring and plumbing.

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

Miscellaneous Specifications

ASTM D2000 Elastomeric Materials

Explore ASTM D2000 elastomeric materials, designed to meet industry standards for performance and durability.

O-Ring Rubber Shelf Life

Learn about the shelf life of O-ring rubber materials, factors affecting longevity, and best storage practices to maintain sealing performance. Ensure your O-rings stay reliable and effective over time.

Vacuum Baking & Cleaning

Explore our specialized services: vacuum baking for material degassing, ultrasonic cleaning for precision parts, and custom bagging for product protection. Request a quote today!

Clean Room Manufactured Materials

Discover clean room manufactured material features, applications, and how they meet strict cleanliness standards in medical, pharmaceutical, and semiconductor environments.

General Purpose Materials Available

Click here to see some of our most commonly served industries!

Each of these materials has its own advantages, limitations, and cost implications. The choice of material usually depends on factors like chemical compatibility, temperature, pressure, dynamic or static use, and specification requirements.

Canyon Components strives to meet all customer service requests. Feel free to contact Canyon Components engineering and let our knowledgeable staff help you design the perfect part for your needs.

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

Back to Industries Hub

Get A Quote Now!

Groove Design References

Learn More

Coatings, Packaging, & Other Services

Learn More

Custom Parts & Custom O-rings

Learn More

FAQ

General purpose O-rings, gaskets, and custom parts provide high performance without the cost or complexity of specialized certifications. While often associated with basic applications, many of these materials can still withstand high temperatures, aggressive chemicals, and demanding mechanical conditions. The key distinction is not performance capability but certification and / or compliance. For instance, Canyon Components offers general purpose Canrez® FFKM compounds that resist extreme temperatures and harsh solvents just like certified grades, but without FDA, USP Class VI, or 3A Sanitary compliances or approvals. This makes them ideal for industrial, mechanical, and processing environments where reliability and cost-effectiveness are top priorities. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

Are general purpose materials still resistant to chemicals and heat?

Yes. Many general purpose compounds perform identically to certified grades in terms of thermal and chemical resistance. For example, general purpose Canrez® FFKM materials are engineered to withstand continuous exposure to high temperatures and aggressive media such as acids, fuels, and solvents. Similarly, FKM and EPDM compounds handle exposure to oils, steam, and industrial fluids at elevated temperatures. The primary difference between these and regulated materials lies in certification documentation, not in inherent chemical or thermal capability. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

Why would I choose a general purpose material over a certified one?

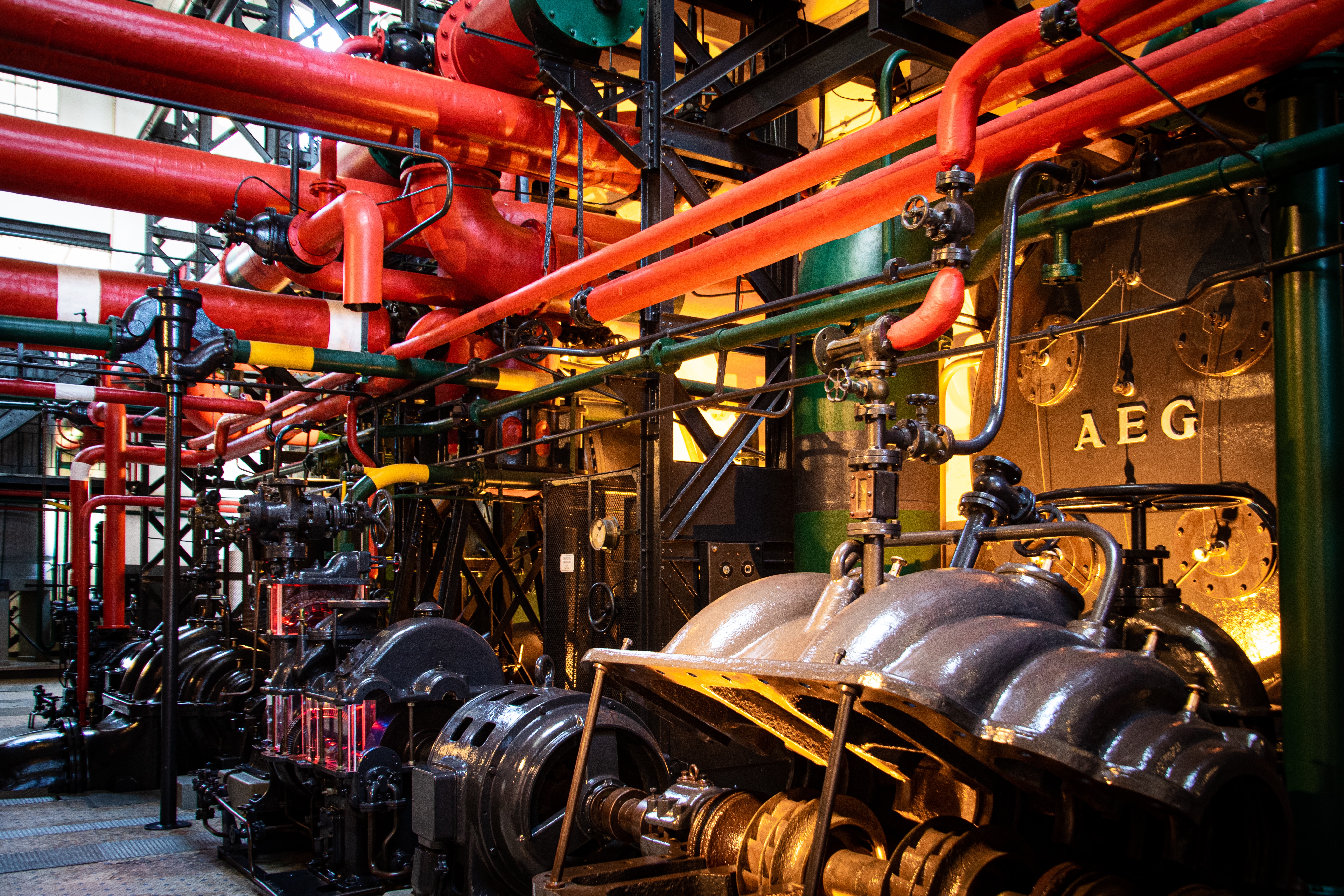

The choice depends on whether your application is regulated. If the part does not come into contact with food, pharmaceuticals, or potable water, using a general purpose material can deliver the same performance at a lower cost. Canyon Components’ general purpose materials are ideal for equipment used in industrial, mechanical, chemical processing, and power generation systems, where safety and performance matter, but specific compliance is not required. These compounds are often preferred for prototypes, maintenance programs, or large-scale production where cost efficiency is key. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What materials are available in general purpose grades?

Canyon Components supplies a broad range of general purpose materials, including NBR (nitrile) for oils and fuels, EPDM for water and steam, FKM (Viton®) for high-heat chemical applications, silicone for flexible thermal sealing, and FFKM for extreme chemical resistance. Many of these are the same base polymers used in certified products, but formulated and produced without additional regulatory testing or documentation. This allows customers to maintain performance consistency across both certified and non-certified systems. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What industries use general purpose O-rings and gaskets?

General purpose sealing materials are used throughout manufacturing, construction, chemical processing, power generation, and mechanical maintenance industries. They are found in pumps, compressors, valves, mixers, hydraulic systems, and thermal processing equipment where sealing reliability under heat and chemical stress is essential. Because they are not limited by regulatory certification, general purpose seals offer exceptional flexibility for custom applications and replacement parts. Canyon Components supports both standard AS568 sizes and fully custom molded geometries to match any industrial requirement. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

Do general purpose materials meet performance standards for durability?

Yes. Canyon Components’ general purpose compounds are produced to meet or exceed ASTM D2000 and ISO 3601 quality benchmarks. They are tested for compression set, tensile strength, elongation, and chemical compatibility to ensure long-term sealing integrity. These materials are validated for repeated thermal cycling and mechanical load, providing dependable service life comparable to certified materials. The only limitation is that they are not audited for regulatory compliance, which simplifies production and reduces cost. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

Can I use general purpose FFKM, FKM, or EPDM in high-temperature applications?

Absolutely. General purpose FFKM compounds, such as Canrez® CP75BK01 and CP75BK20, are suitable for sustained exposure above 600°F and maintain excellent elasticity and chemical resistance. FKM and EPDM also perform exceptionally in continuous heat and pressure environments. These materials are widely used in pumps, reactors, and process lines where chemical and thermal stress are severe but regulatory approval is not necessary. Canyon Components can help match each material’s thermal range and chemical compatibility to your specific system conditions. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

How does Canyon Components ensure the reliability of non-certified materials?

Even without formal compliance certifications, all Canyon Components general purpose materials undergo stringent internal testing and quality control. Compounds are verified for hardness, cure consistency, and chemical resistance before production begins. Each batch is documented for traceability and tested for mechanical integrity to ensure performance consistency. Customers receive material data sheets and testing information upon request, providing confidence in both short-term function and long-term reliability. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

Can general purpose materials be customized for unique industrial requirements?

Yes. Canyon Components specializes in custom molding, extrusion, and fabrication of general purpose materials. We can adjust hardness, filler content, and color to achieve specific performance characteristics such as low compression set, increased chemical resistance, or enhanced flexibility. Our engineering team also assists in designing custom O-ring, gasket, or seal geometries that optimize performance in dynamic or static applications. General purpose materials are available in standard and specialty elastomer families, allowing full design freedom without regulatory constraints. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What makes Canyon Components’ general purpose materials a practical choice?

Canyon Components’ general purpose O-rings, gaskets, and seals bridge the gap between affordability and performance. They are made from the same high-quality polymers used in specialized applications but offered without the added cost of certification. This approach provides customers with premium chemical and thermal resistance at a lower overall cost, ideal for industrial environments where documentation is not required. Our commitment to consistent quality, fast turnaround, and expert engineering ensures that every general purpose part delivers dependable performance, long service life, and exceptional value. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!