Contact Us

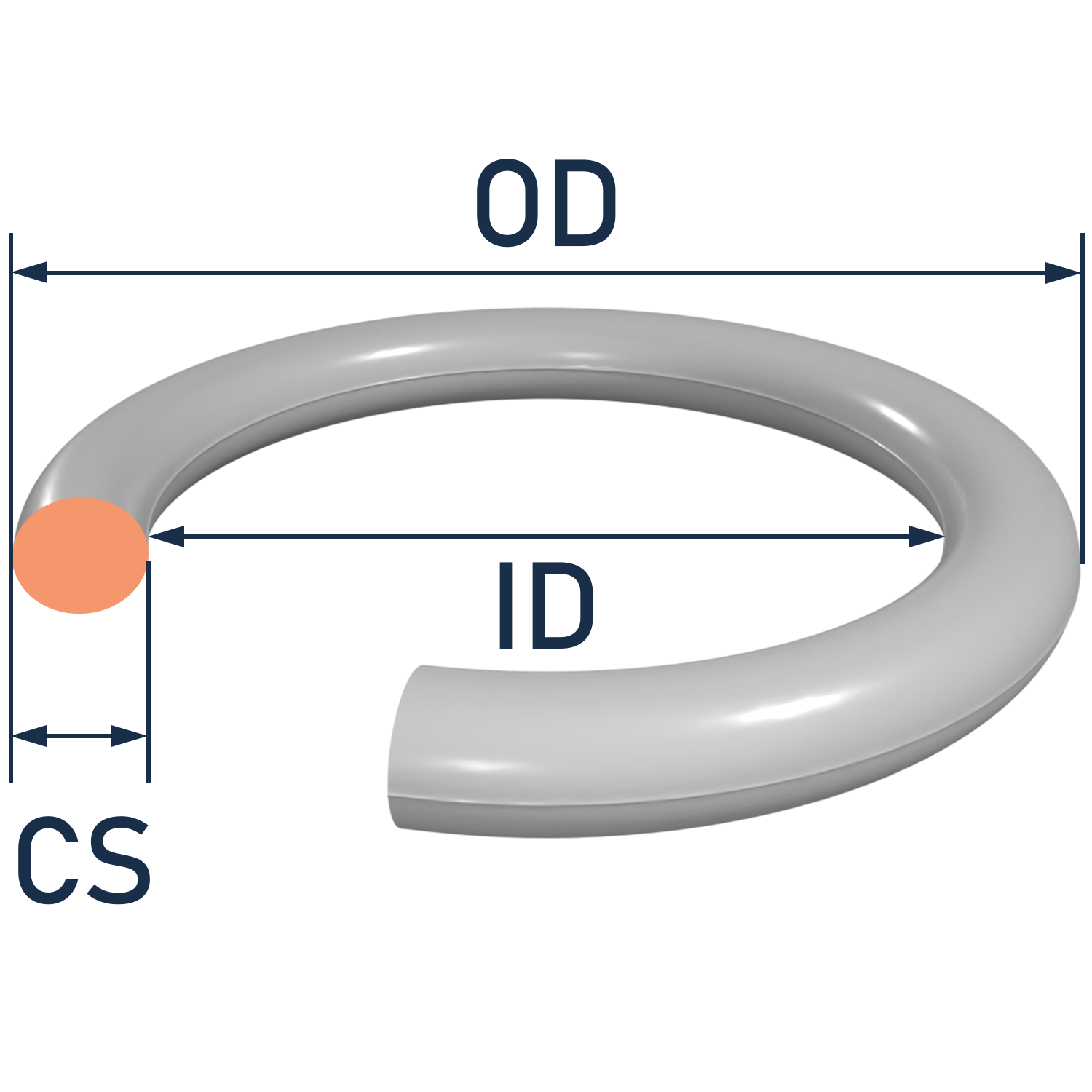

Rod & Piston (Static) Design Guide

'Rod' & 'Piston' styled O-ring grooves are commonly used O-ring sealing configurations. This page specifically concerns static (unmoving) Rod & Piston O-ring seals.

The purpose of the tables below are to serve as a design guide for static Rod & Piston O-ring grooves using AS568 O-ring sizes*.

* Please note that some AS568-0XX O-rings have atypical cross sections. Please see our General Groove Guide for more information, or feel free to get in touch with our engineers if you have any questions about O-rings, gaskets, & custom molded parts.

Surface Finish X: 32 RMS for liquids, 16 RMS for vacuum and gases

| DASH # RANGE | O-RING CROSS SECTION | GLAND DEPTH (D) | SQUEEZE | GLAND WIDTH (W) | CLEARANCE (H) | GLAND CORNER RADIUS | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AS568 | Nominal (in) | Nominal (in) | Actual (in) | Percent | Nominal (in) | Nominal (in) | R1 (in) | R2 (in) | |||||

| -004 through -050 | 0.070 ± 0.003 | 0.050 - 0.052 | 0.015 - 0.023 | 22 - 32 | 0.093 - 0.098 | 0.002 | 0.01 | 0.005 | |||||

| -102 through -178 | 0.103 ± 0.003 | 0.081 - 0.083 | 0.017 - 0.025 | 17 - 24 | 0.140 - 0.145 | 0.002 | 0.01 | 0.005 | |||||

| -201 through -284 | 0.139 ± 0.004 | 0.111 - 0.113 | 0.022 - 0.032 | 16 - 23 | 0.187 - 0.192 | 0.002 | 0.018 | 0.005 | |||||

| -309 through -395 | 0.210 ± 0.005 | 0.170 - 0.173 | 0.032 - 0.045 | 15 - 21 | 0.281 - 0.286 | 0.003 | 0.028 | 0.005 | |||||

| -425 through -475 | 0.275 ± 0.006 | 0.226 - 0.229 | 0.040 - 0.055 | 15 - 20 | 0.375 - 0.380 | 0.003 | 0.028 | 0.005 | |||||

Back to Reference Hub

Get A Quote Now!

Groove Design References

Learn More

Coatings, Packaging, & Other Services

Learn More

Custom Parts & Custom O-rings

Learn More