Metal Detectable O-rings, Gaskets, Elastomers

Metal detectable O-rings, gaskets, and elastomers are specialized sealing components designed for use in industries where contamination control is critical. These seals are formulated with metal additives, allowing them to be detected by metal detectors if they inadvertently enter the production process. This guide explores the features, common applications, and the pros and cons of using metal detectable seals in your systems.

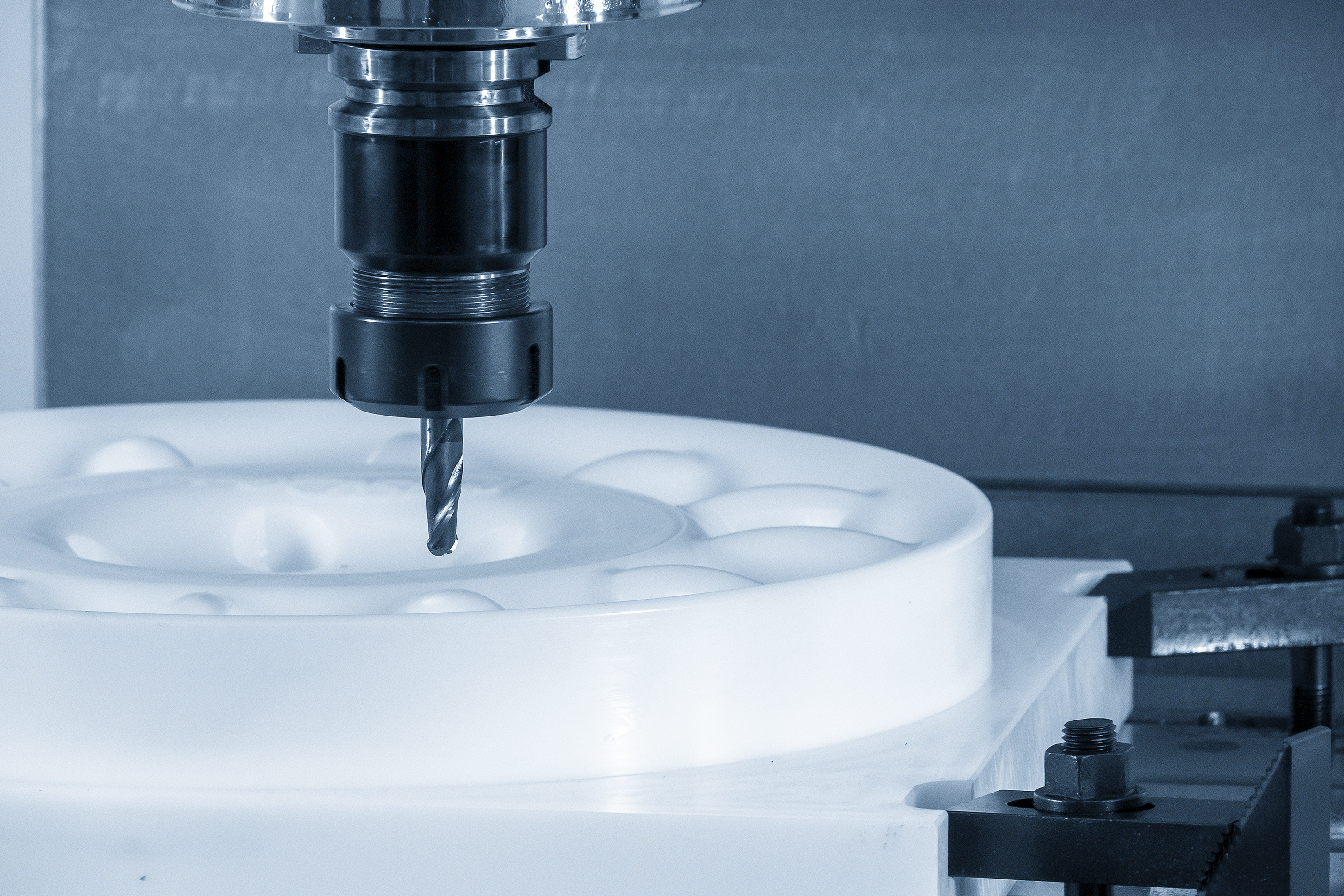

Metal detectable O-rings, gasket rapid manufacturing, & custom molded parts are available now!

Check with one of Canyon’s helpful product engineers for an expert material and manufacturing recommendation.

Request a Quote for Metal Detectable O-rings, Gaskets, and Elastomers

Pros of Metal Detectable O-Rings, Gaskets, and Elastomers

Metal detectable seals offer several advantages that make them an excellent choice for contamination-sensitive industries:

- Enhanced Safety: The ability to detect seal fragments in the production process helps prevent contamination, protecting consumers and ensuring product quality.

- Regulatory Compliance: Metal detectable seals often meet industry-specific regulations, such as FDA or EU standards, making it easier to achieve compliance with safety requirements.

- Reduced Downtime: By preventing contamination incidents, metal detectable seals help reduce the risk of costly recalls, product waste, and downtime associated with cleaning and repairs.

- Versatility: Available in various materials and sizes, metal detectable seals can be customized to fit specific applications, providing flexibility in design and use.

- Easy Identification: The distinct color coding of metal detectable seals makes them easy to identify during inspections, further enhancing safety measures.

Cons of Metal Detectable O-Rings, Gaskets, and Elastomers

While metal detectable seals offer significant benefits, there are also some drawbacks to consider:

- Higher Cost: Metal detectable seals are typically more expensive than standard seals due to the specialized materials and manufacturing processes required.

- Limited Material Choices: Although metal detectable seals are available in a variety of materials, the range of options may be more limited compared to non-metal detectable alternatives.

- Potential for False Positives: In some cases, metal detectors may detect small fragments of seals that do not pose a contamination risk, leading to false positives and unnecessary downtime.

- Material Trade-offs: The addition of metal additives can sometimes affect the physical properties of the seal material, such as reducing flexibility or increasing wear, depending on the specific application.

Features of Metal Detectable O-Rings, Gaskets, and Elastomers

Metal detectable seals offer several unique features that make them ideal for specific industries:

- Contamination Control: The primary feature of metal detectable seals is their ability to be detected by standard metal detection equipment. This helps prevent contaminated products from reaching consumers.

- Durability: These seals are designed to withstand harsh processing environments, including high temperatures, chemicals, and abrasion.

- Compliance: Metal detectable seals often meet strict industry regulations, such as FDA or EU food safety standards, making them suitable for use in food and pharmaceutical industries.

- Versatility: Available in various materials, including Nitrile, EPDM, and Silicone, metal detectable seals can be tailored to specific application requirements.

- Color Coding: Many metal detectable seals are colored blue or other easily visible colors, further enhancing their detectability in processing environments.

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

Metal Detectable Materials Available

This table shows many of our standard materials and links out to our O-ring store. Get in touch with us if you need a custom gasket, custom molded part, or non-standard geometry!

Filter by

Temperature Search (°C)

Common Applications of Metal Detectable O-Rings, Gaskets, and Elastomers

Metal detectable O-rings, gaskets, and elastomers are essential components in industries where contamination control is critical, such as food, beverage, and pharmaceutical manufacturing. By offering enhanced safety, regulatory compliance, and versatility, these seals help prevent contamination incidents and protect consumers. However, it's essential to consider the potential drawbacks, such as higher costs and material trade-offs, when selecting metal detectable seals for your application. With the right choice of material and design, metal detectable seals can provide reliable performance and peace of mind in contamination-sensitive environments.

Metal detectable seals are used in industries where contamination prevention is critical. Common applications include:

Canyon Components strives to meet all customer service requests. Feel free to contact Canyon Components engineering and let our knowledgeable staff help you design the perfect part for your needs.

Food and Beverage Processing

Metal detectable O-rings and gaskets are used in equipment like mixers, pumps, and conveyors to prevent contamination in food products.

Pharmaceutical Manufacturing

In pharmaceutical production, metal detectable seals help ensure the purity and safety of medications by preventing seal fragments from entering the product stream.

Packaging Equipment

Metal detectable seals are used in packaging machinery to reduce the risk of contamination and ensure product safety.

Dairy and Meat Processing

These seals are commonly found in dairy and meat processing equipment, where hygiene and contamination control are paramount.

Brewing and Beverage Systems

Metal detectable seals are used in brewing and beverage systems to ensure the integrity and safety of the final product.

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

Back to Products Hub

Get A Quote Now!

Groove Design References

Learn More

Coatings, Packaging, & Other Services

Learn More

Custom Parts & Custom O-rings

Learn More