Engineering Services for O-Rings, Gaskets, and Custom Rubber, Plastic, and Metal Parts

Our reverse engineering services provide comprehensive solutions for replicating and improving existing O-rings, gaskets, and custom parts made from rubber, plastic, and metal. Whether you need to replace obsolete components, improve design efficiency, or reduce costs, our expertise in reverse engineering ensures that you receive high-quality parts that meet or exceed your original specifications. This guide outlines our services, including reverse engineering, material testing and identification, rapid prototyping, and custom assemblies, with a focus on cost savings and improved designs.

CanRez® FFKM and Kalrez® O-rings, gasket rapid manufacturing, & custom molded parts are available now!

Check with one of Canyon’s helpful product engineers for an expert material and manufacturing recommendation.

Reverse Engineering

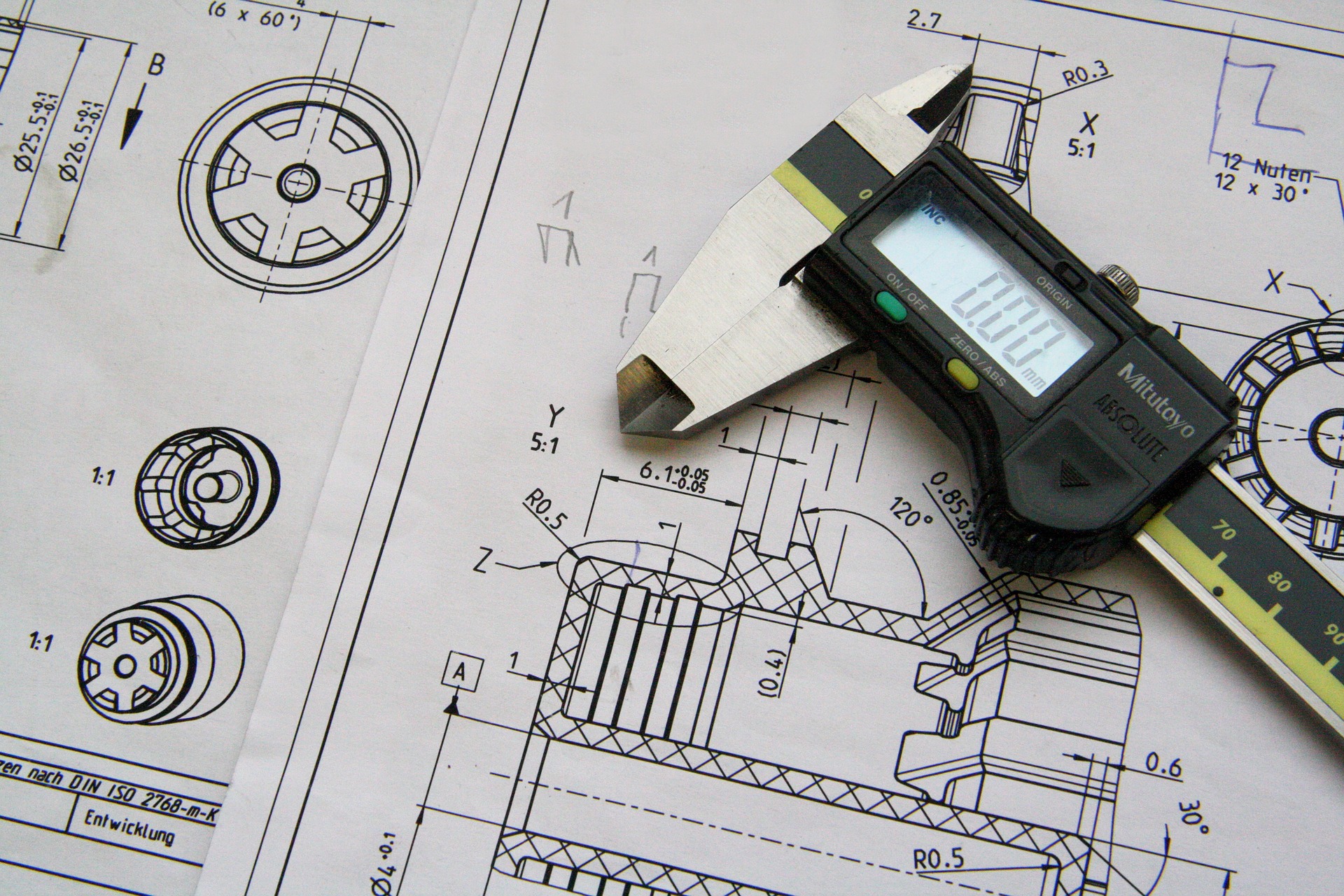

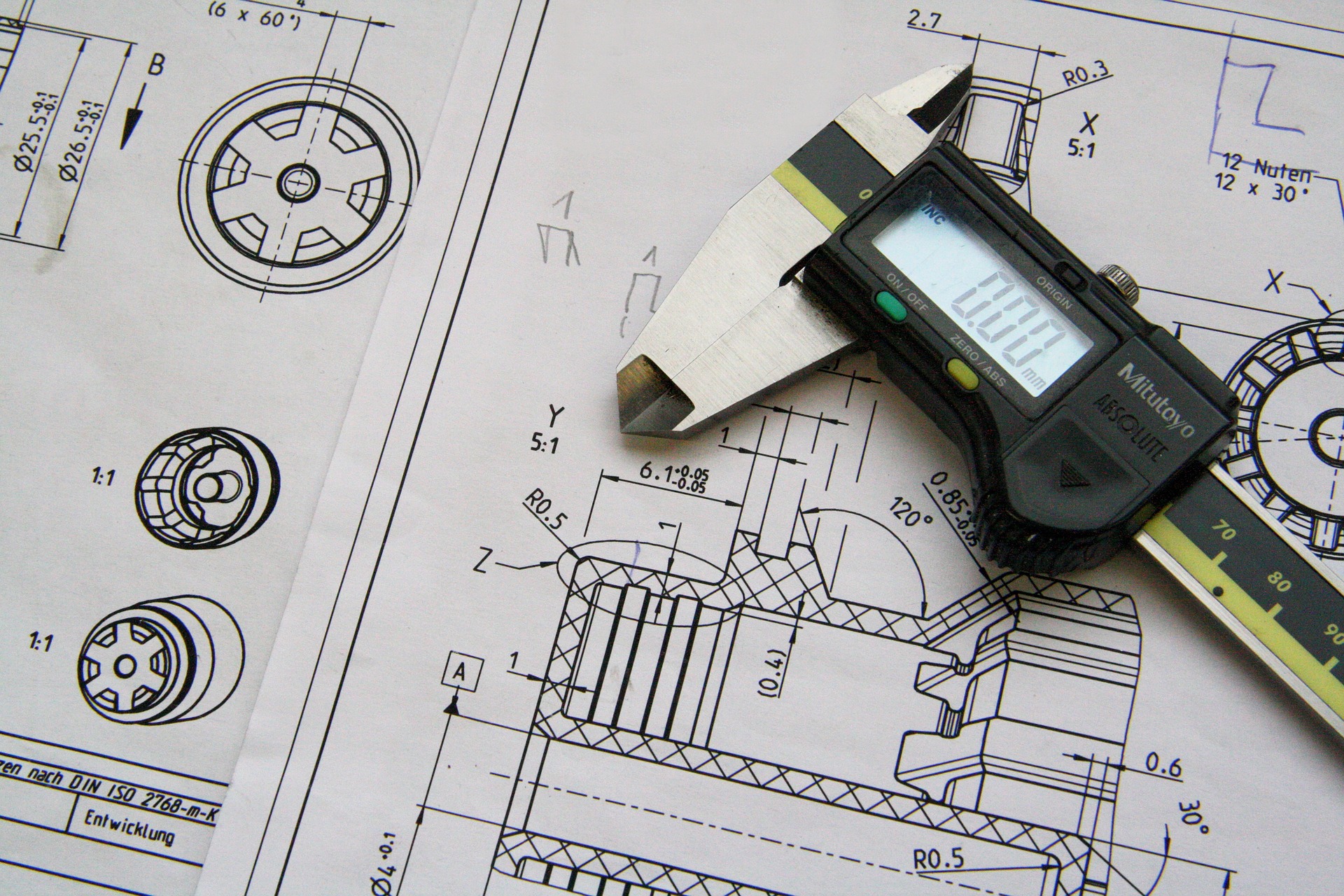

Reverse engineering is the process of deconstructing an existing part to understand its design, material composition, and manufacturing process. Our reverse engineering services include:

- Detailed Analysis: We begin by analyzing the original part to capture its dimensions, material properties, and functional requirements. This step ensures that the new part will perform identically or better than the original.

- CAD Modeling: Our engineers use the scanned data to create accurate CAD models, which serve as the foundation for manufacturing new parts.

- 3D Scanning: Utilizing advanced 3D scanning technology, we can create precise digital models of the part if needed, capturing even the most intricate details.

- Design Optimization: During the reverse engineering process, we identify opportunities for design improvements, such as enhancing durability, reducing material costs, or simplifying manufacturing.

By leveraging reverse engineering, we can reproduce parts that are no longer available or optimize existing designs for better performance and cost-efficiency.

Material Testing and Identification

Understanding the material composition of your parts is crucial for ensuring compatibility and performance. Learn more here! Our material testing and identification services include:

- Chemical Analysis: We perform chemical analysis to determine the exact composition of the materials used in your parts, ensuring that replacements meet the same standards.

- Physical Testing: Our lab conducts physical tests to assess properties such as hardness, tensile strength, and elasticity, ensuring that the new parts will perform reliably in your specific application.

- Material Matching: Based on the results of our tests, we recommend the most suitable materials for your parts, whether you need to match the original material or upgrade to a more advanced option.

By accurately identifying and testing materials, we ensure that your parts are made from the best possible materials, leading to improved performance and longer service life.

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

Request Engineering Services

Rapid Prototyping

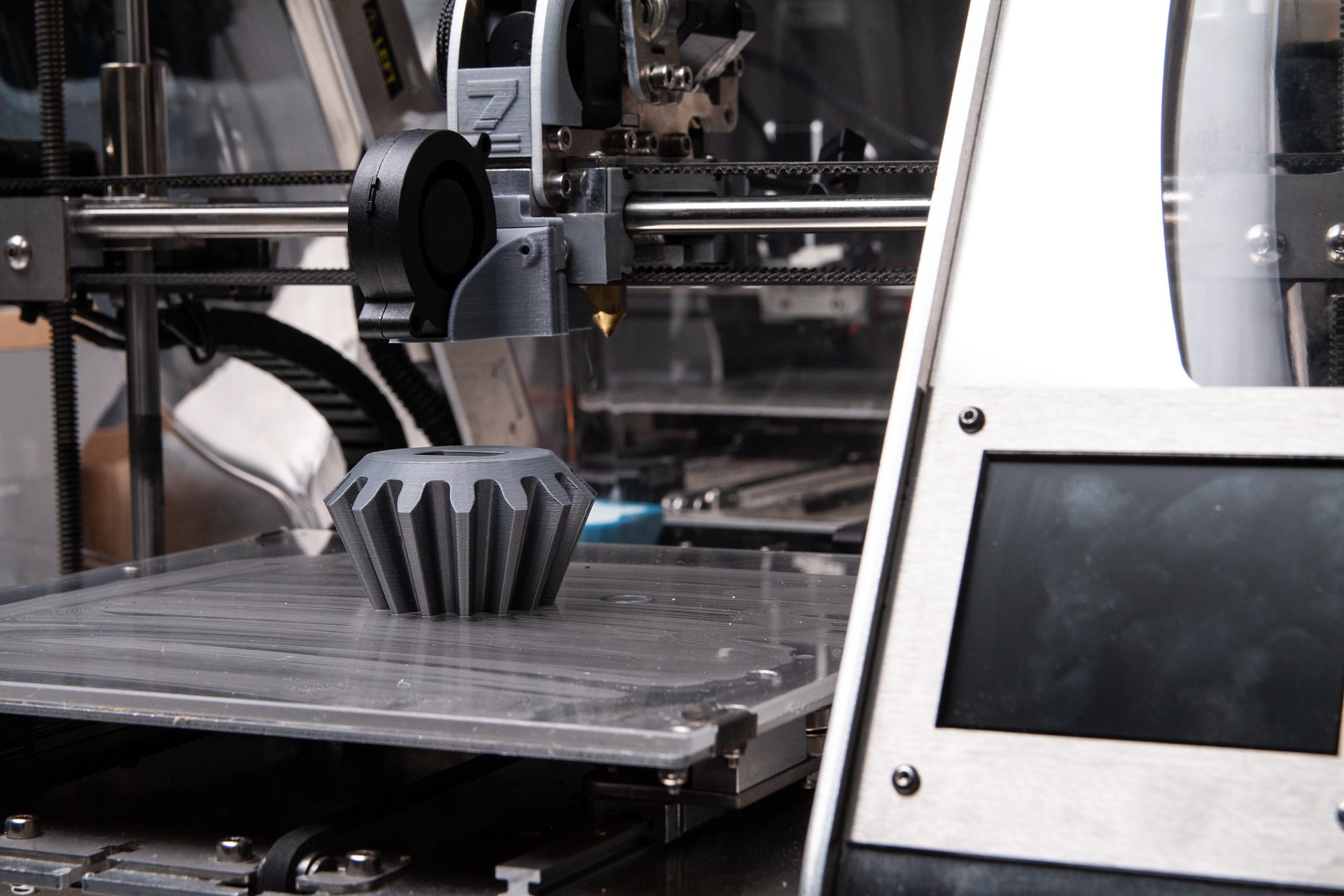

Speed is critical when you need to replace or improve parts quickly. Our rapid prototyping services enable you to:

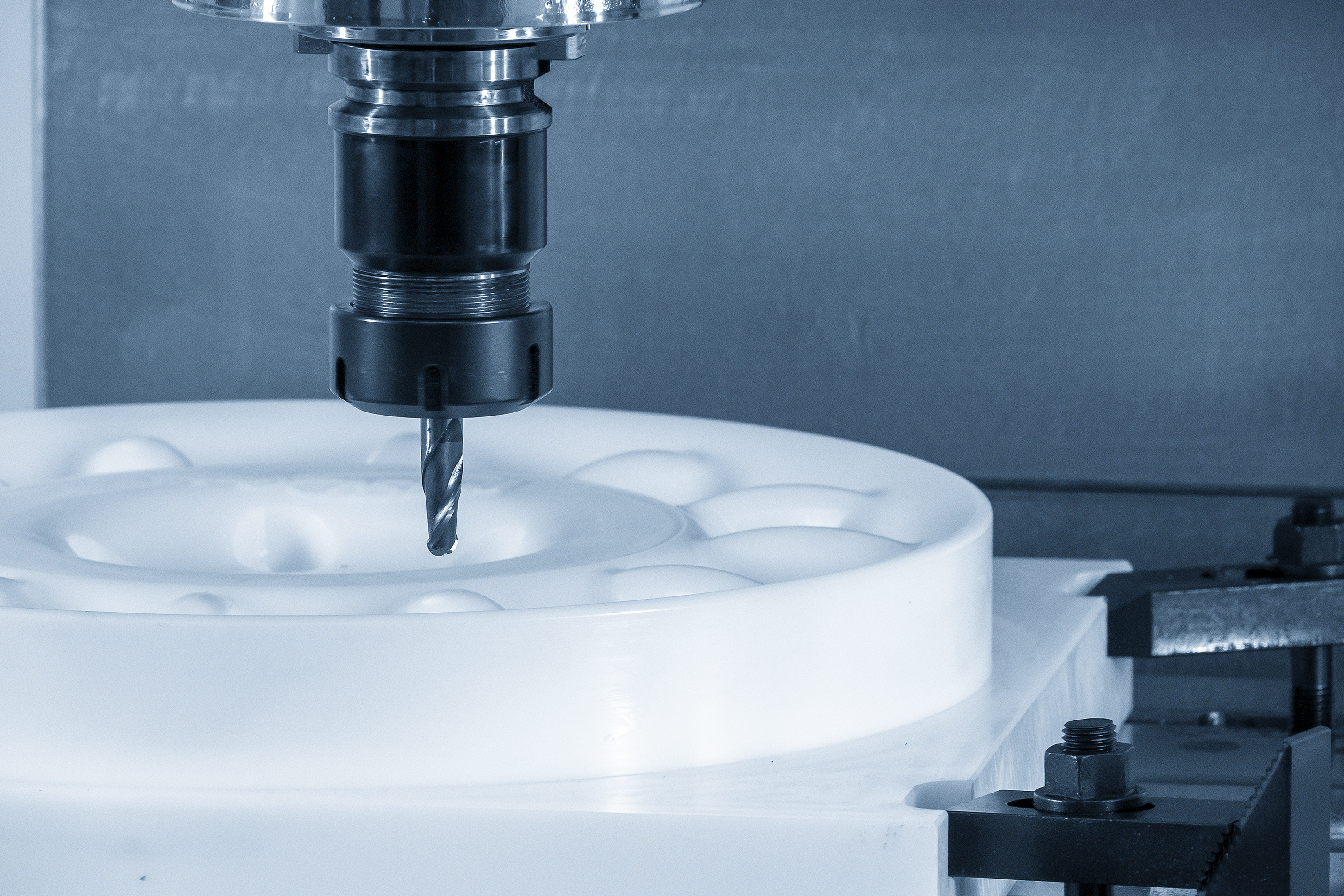

- Quickly Validate Designs: Using advanced 3D printing and CNC machining technologies, we can produce prototypes rapidly, allowing you to test and validate designs before committing to full-scale production.

- Iterative Development: Rapid prototyping allows for multiple iterations of a design, enabling you to refine and optimize your parts based on real-world testing and feedback.

- Cost-Efficient Development: By producing prototypes quickly and efficiently, we help you reduce development costs and time to market.

Our rapid prototyping services ensure that you receive functional prototypes quickly, allowing you to make informed decisions and reduce overall project timelines.

Canyon Components strives to meet all customer service requests. Feel free to contact Canyon Components engineering and let our knowledgeable staff help you design the perfect part for your needs.

Engineering Services

Our reverse engineering services for O-rings, gaskets, and custom parts provide you with the expertise and technology needed to reproduce, improve, and optimize your components. From material testing and rapid prototyping to custom assemblies and design optimization, we offer comprehensive solutions that deliver cost savings, enhanced performance, and extended part life. Whether you're dealing with obsolete parts or looking to improve your current designs, our reverse engineering services ensure that you get the best possible results for your projects.

Canyon Components strives to meet all customer service requests. Feel free to contact Canyon Components engineering and let our knowledgeable staff help you design the perfect part for your needs.

Custom Assemblies

In addition to reverse engineering individual components, we also specialize in custom assemblies. Our services include:

- Integrated Solutions: We can reverse engineer and assemble complex systems that involve multiple components, ensuring that each part works seamlessly together.

- Design for Manufacturability: Our engineers optimize custom assemblies for manufacturability, reducing production costs and ensuring consistent quality.

- Assembly Testing: We rigorously test each assembly to ensure that it meets all functional and performance requirements, providing you with reliable, ready-to-use solutions.

By offering custom assemblies, we provide you with complete solutions that are tailored to your specific needs, improving efficiency and reducing the need for multiple suppliers.

Custom Assemblies

One of the key benefits of our reverse engineering services is the potential for significant cost savings and design improvements:

- Reduce Production Costs: By optimizing designs and material selection, we help you reduce production costs without compromising on quality or performance.

- Extend Part Life: Improved materials and design enhancements can extend the life of your parts, reducing the frequency of replacements and lowering maintenance costs.

- Eliminate Obsolescence: Reverse engineering allows you to continue using equipment even when original parts are no longer available, eliminating the need for expensive equipment upgrades.

- Enhance Performance: Through design optimization and material upgrades, we can improve the performance of your parts, leading to greater efficiency and reliability in your operations.

Our focus on cost savings and improved designs ensures that you receive high-quality parts that offer better value and performance over time.

Back to Products Hub

Get A Quote Now!