X-Ray Detectable O-rings, Gaskets, Elastomers

X-ray detectable O-rings, gaskets, and elastomers are specialized sealing components designed for use in industries where contamination control and product integrity are paramount. These seals are formulated with materials that allow them to be detected by X-ray inspection systems, ensuring that any fragments or pieces that enter the production process can be identified and removed. This guide explores the features, common applications, and the pros and cons of using X-ray detectable seals in your systems.

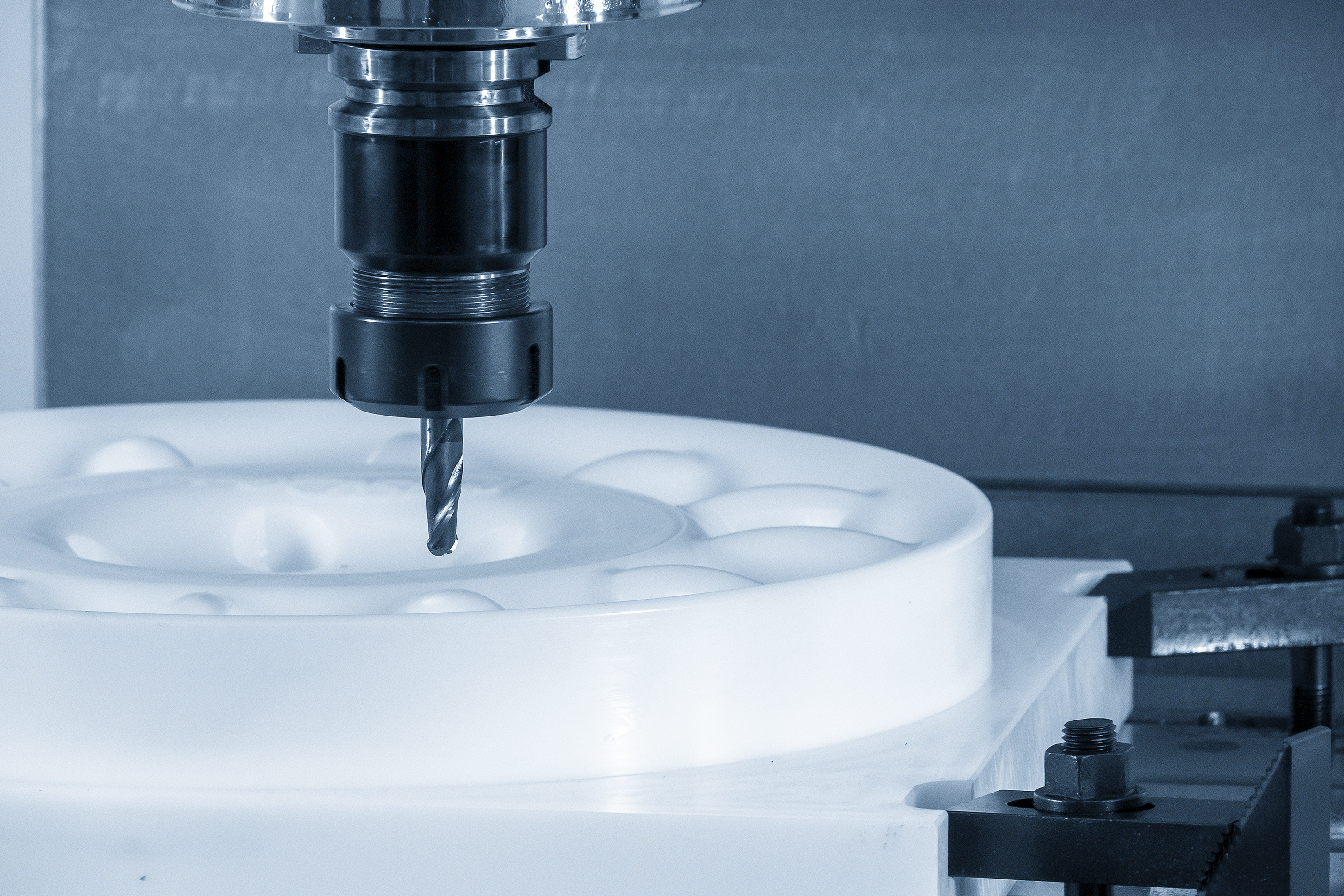

X-ray detectable O-rings, gasket rapid manufacturing, & custom molded parts are available now!

Check with one of Canyon’s helpful product engineers for an expert material and manufacturing recommendation.

Request a Quote for X-Ray Detectable O-rings, Gaskets, and Elastomers

Pros of X-Ray Detectable O-Rings, Gaskets, and Elastomers

X-ray detectable seals offer several advantages that make them a valuable choice in contamination-sensitive environments:

- Enhanced Safety: The ability to detect even small fragments of seals helps prevent contaminated products from reaching consumers, reducing the risk of recalls and protecting brand reputation.

- Regulatory Compliance: Many industries require compliance with stringent safety standards, and X-ray detectable seals help meet these requirements.

- Versatility: With a range of material options, X-ray detectable seals can be used in a variety of applications, from high-temperature processes to chemically aggressive environments.

- Cost-Efficient: By preventing contamination and reducing the risk of recalls, X-ray detectable seals can lead to significant cost savings over time.

Cons of X-Ray Detectable O-Rings, Gaskets, and Elastomer

While X-ray detectable seals offer many benefits, there are also some potential drawbacks to consider:

- Higher Cost: X-ray detectable materials can be more expensive than standard seals, which may increase the overall cost of the product or system.

- Limited Detection Equipment: Not all facilities may have the necessary X-ray detection systems in place, which could limit the effectiveness of these seals in certain environments.

- Material Limitations: While X-ray detectable seals are available in various materials, not all material types may be suitable for every application, and customization may be required.

Features of X-Ray Detectable O-Rings, Gaskets, and Elastomers

X-ray detectable seals offer several important features that make them ideal for specific applications:

- X-Ray Visibility: The primary feature of these seals is their ability to be detected by X-ray inspection systems, helping to prevent contamination in sensitive products.

- High Durability: X-ray detectable seals are designed to withstand harsh environments, including exposure to high temperatures, chemicals, and mechanical stress.

- Compliance: Many X-ray detectable seals meet strict regulatory standards, such as FDA or EU regulations, making them suitable for use in food processing, pharmaceuticals, and other safety-critical industries.

- Versatility: Available in a variety of materials, including Silicone, EPDM, and Nitrile, X-ray detectable seals can be customized to meet the specific needs of different applications.

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

Common Applications of X-Ray Detectable O-Rings, Gaskets, and Elastomers

X-ray detectable O-rings, gaskets, and elastomers provide a critical solution for industries where contamination control and product safety are top priorities. By offering enhanced safety, regulatory compliance, and versatility, these seals play a vital role in ensuring the integrity of food, pharmaceuticals, and other sensitive products. However, the higher cost and need for specific detection equipment should be considered when selecting X-ray detectable seals for your application.

X-Ray detectable seals are used in industries where contamination prevention is critical. Common applications include:

Canyon Components strives to meet all customer service requests. Feel free to contact Canyon Components engineering and let our knowledgeable staff help you design the perfect part for your needs.

Food and Beverage Processing

X-ray detectable O-rings and gaskets are used in processing equipment to ensure that no foreign objects enter the final product, protecting consumer safety.

Pharmaceutical Manufacturing

In pharmaceutical production, X-ray detectable seals help ensure that products remain free from contamination by seal fragments or other foreign materials.

Medical Devices

X-ray detectable elastomers are used in medical devices to ensure that any potential contamination can be quickly identified and addressed during production.

Packaging Equipment

X-ray detectable seals are also used in packaging machinery to maintain product integrity and prevent contamination from damaged seals or gaskets.

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

Back to Products Hub

Get A Quote Now!

Groove Design References

Learn More

Coatings, Packaging, & Other Services

Learn More

Custom Parts & Custom O-rings

Learn More