NSF 61 Materials

NSF 61 materials are specifically designed for use in applications involving drinking water and potable water systems. Certified by the National Sanitation Foundation (NSF), these materials ensure that no harmful contaminants leach into the water, making them safe for use in municipal water systems, plumbing, and other applications involving potable water. This guide covers the features, common applications, and the pros and cons of NSF 61 materials.

NSF 61 CanRez® FFKM and Kalrez® O-rings, gasket rapid manufacturing, & custom molded parts are available now!

Check with one of Canyon’s helpful product engineers for an expert material and manufacturing recommendation.

Features of NSF 61 Materials

NSF 61 materials are engineered to meet strict safety and performance standards, offering several key features:

- Non-Toxic and Safe for Drinking Water: NSF 61 materials are rigorously tested to ensure that they do not leach harmful chemicals, heavy metals, or other contaminants into drinking water.

- Chemical Resistance: These materials are resistant to the various chemicals and treatments commonly used in water systems, such as chlorine, ensuring long-term performance without degradation.

- Durability and Long-Term Use: NSF 61 materials are designed to withstand continuous exposure to water and environmental factors, maintaining their structural integrity over time.

- Compliance with Health Standards: NSF 61 certification ensures that materials meet or exceed the health standards for potable water systems set by regulatory bodies.

- Wide Temperature Range: Many NSF 61 materials are capable of withstanding both cold and hot water applications, making them versatile for use in various environments.

Common Applications of NSF 61 Materials

NSF 61 materials are widely used in systems and components that come into contact with potable water. Some common applications include:

- Municipal Water Systems: NSF 61 materials are used in pipes, gaskets, seals, and valves to ensure that the water supplied to homes and businesses remains safe and uncontaminated.

- Plumbing Systems: These materials are used in household plumbing fixtures, including faucets, connectors, and pipes, to prevent the leaching of harmful substances into drinking water.

- Water Treatment Facilities: NSF 61 materials are used in components such as filters, valves, and seals in water treatment facilities to ensure that water remains safe for consumption after treatment.

- Irrigation Systems: In agricultural and landscaping applications, NSF 61 materials are used in piping and valves to ensure that water used for irrigation remains uncontaminated and safe for plants.

- Water Storage Tanks: NSF 61 materials are used in gaskets, seals, and liners for water storage tanks, preventing contamination from the tank walls into the stored potable water.

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

NSF 61 Materials Available

This table shows many of our standard materials and links out to our O-ring store. Get in touch with us if you need a custom gasket, custom molded part, or non-standard geometry!

Filter by

Temperature Search (°C)

Get a Quote Now!

NSF 61 Elastomers

Drinking Water Materials

Explore NSF 61 materials, certified for use in drinking water and potable systems. Learn about their features, compliance with safety standards, and how they ensure clean, safe water in various applications.

Specialty Compliances

Canyon have materials available for O-rings, gaskets, & custom parts with compliances ranging from USP Class VI <87> & <88> for medical applications, to FDA CFR 21.177.2600 grades A through F for different food types, to the various drinking water specifications like KTW and NSF. Whether it's metal, rubber, or plastic, Canyon can meet your needs!

Custom Parts

Here at Canyon Components, we make sure to offer our customers any manufacturing technique they desire. Whether your NSF 61 O-rings, gaskets, & custom molded parts be rubber, plastic, or metal, rest assured that Canyon Components can make it!

CanRez™ FFKM Perfluoroelastomer

Extreme temperatures & chemicals require extreme solutions! NSF 61 CanRez™ FFKM materials offer extreme reliability where you need it most! Thousands of sizes in stock now!

Kalrez® FFKM Perfluoroelastomer

Canyon Components offers NSF 61 Kalrez® Perfluoroelastomer (FFKM) O-rings, gaskets, & custom molded parts at competitive prices and with great lead-times.

NSF 61 Parker® O-rings, Parofluor parts, parker FKM Viton

Canyon Components offers NSF 61 Parker Hannifin® O-rings, Gaskets, NSF 61 Perfluoroelastomer (FFKM) parts, & custom molded parts at competitive prices and with great lead-times.

FKM (Viton®, Fluorocarbon)

NSF 61 FKM compounds, O-rings, gaskets, & custom molded parts exhibit excellent mechanical attributes as well as excellent resistance to high temperatures, mineral oil, ozone, fuels, hydraulic fluids, and many other solvents and chemicals.

Fluorosilicone (FVMQ)

The mechanical and physical properties of NSF 61 Fluorosilicone O-rings, gaskets, & custom molded parts are very similar to silicone. Fluorosilicone O-rings, gaskets, & custom molded parts offer improved flexibility and strength, better resistance to fuels and mineral oil, but reduced hot air resistance.

Silicone (VMQ, PVMQ)

NSF 61 Silicone seals, O-rings, gaskets, & custom molded parts are excellent for extreme temperatures in static applications. Canyon Components carries a range of silicone materials, and we are happy to custom tailor a seal to meet your application requirements!

EPDM (Ethylene Propylene)

NSF 61 EPDM materials, O-rings, gaskets, & custom molded parts can operate over a wide temperature range, and are compatible with glycol fluids that cause problems for most typical elastomeric seals.

NBR (Nitrile, Buna-N)

NSF 61 Nitrile O-rings, gaskets, & custom molded parts are very oil-resistant, have strong mechanical properties, are resistant to wear, and are relatively inexpensive. These properties make Nitrile the most commonly used general purpose O-ring, gasket, & custom molded part material.

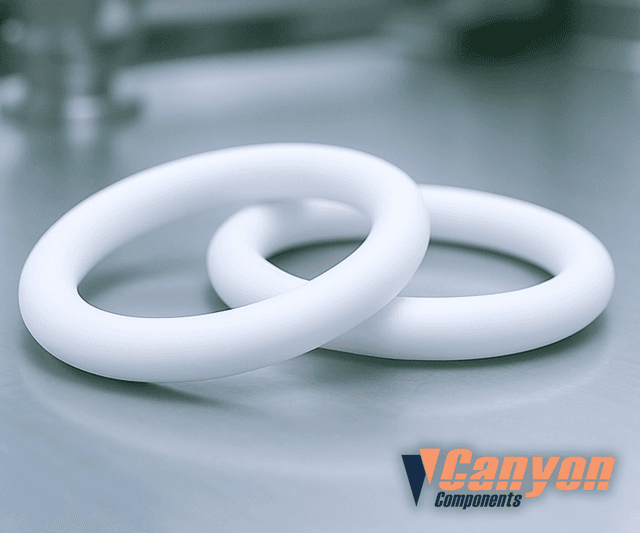

PTFE Encapsulated

NSF 61 FEP and PFA encapsulated O-rings consist of an elastomeric core and a seamlessly closed casing of modified PTFE. The elastomer core of encapsulated O-rings is typically made of FKM (Viton) or VMQ (silicone) and guarantees a uniform pre-tensioning at the sealing point.

PTFE (Teflon)

The harshest environments require specialized solutions. Often times, a Canyon Components NSF 61 PTFE O-rings are used in harsh chemical environments. Polytetrafluoroethylene, commonly known as PTFE or Teflon®, is a high-performance fluoropolymer known for its exceptional chemical resistance, low friction, and non-stick properties.

NSF 61 Plastics

NSF 61 Materials Pros & Cons

NSF 61 materials are an essential component in potable water systems, ensuring the safety and purity of drinking water. With features such as chemical resistance, durability, and compliance with health standards, these materials are used in a wide range of applications, from municipal water systems to household plumbing. While they may come with higher costs and more complex manufacturing requirements, the safety, regulatory compliance, and long-term performance they provide make NSF 61 materials a valuable investment in the health and well-being of consumers. Understanding the features, applications, and pros and cons of NSF 61 materials will help you make informed decisions when selecting materials for your water system projects.

Canyon Components strives to meet all customer service requests. Feel free to contact Canyon Components engineering and let our knowledgeable staff help you design the perfect part for your needs.

Pros of NSF 61 Materials

NSF 61 materials offer several advantages that make them a preferred choice for potable water systems:

- Health and Safety Assurance: The primary benefit of NSF 61 materials is their safety for use in drinking water systems, ensuring that no harmful substances leach into the water supply.

- Compliance with Regulations: Using NSF 61-certified materials ensures that your water system meets all regulatory requirements for potable water applications, minimizing the risk of non-compliance or legal issues.

- Durability: NSF 61 materials are designed to last, resisting wear and tear from continuous exposure to water and chemicals, leading to fewer replacements and lower maintenance costs.

- Versatility: These materials can be used in a wide range of applications, from household plumbing to large-scale municipal water systems, thanks to their chemical resistance and temperature tolerance.

- Environmental Resistance: Many NSF 61 materials are designed to resist environmental factors such as UV radiation, making them suitable for both indoor and outdoor water systems.

Cons of NSF 61 Materials

While NSF 61 materials offer many benefits, there are also some potential drawbacks to consider:

- Higher Cost: The certification process and testing required for NSF 61 materials can lead to higher costs compared to non-certified materials, making them more expensive for some applications.

- Limited Material Selection: Not all materials are eligible for NSF 61 certification, which may limit the range of materials available for specific applications.

- Complex Manufacturing Requirements: Manufacturing NSF 61 materials requires strict adherence to safety and quality standards, which can increase production complexity and lead times.

- Performance Trade-offs: In some cases, the properties required for NSF 61 certification, such as reduced leaching potential, may lead to trade-offs in mechanical strength or flexibility compared to non-certified materials.

Relevant Compliances

WRAS Materials: Certified Solutions for Safe Drinking Water Systems

Explore WRAS materials, certified for use in potable water systems. Learn about their features, compliance with safety standards, and how they ensure the integrity of drinking water systems in various industries.

KTW Materials: Certified Solutions for Drinking Water and Potable Systems

Discover KTW materials, approved for use in drinking water systems. Learn about their features, compliance with German water standards, and how they ensure safety and reliability in potable water applications.

Materials for Drinking Water

Discover materials for drinking water: safe, certified options designed to meet rigorous health standards for water distribution and storage.

Back to Compliance Hub

Get A Quote Now!