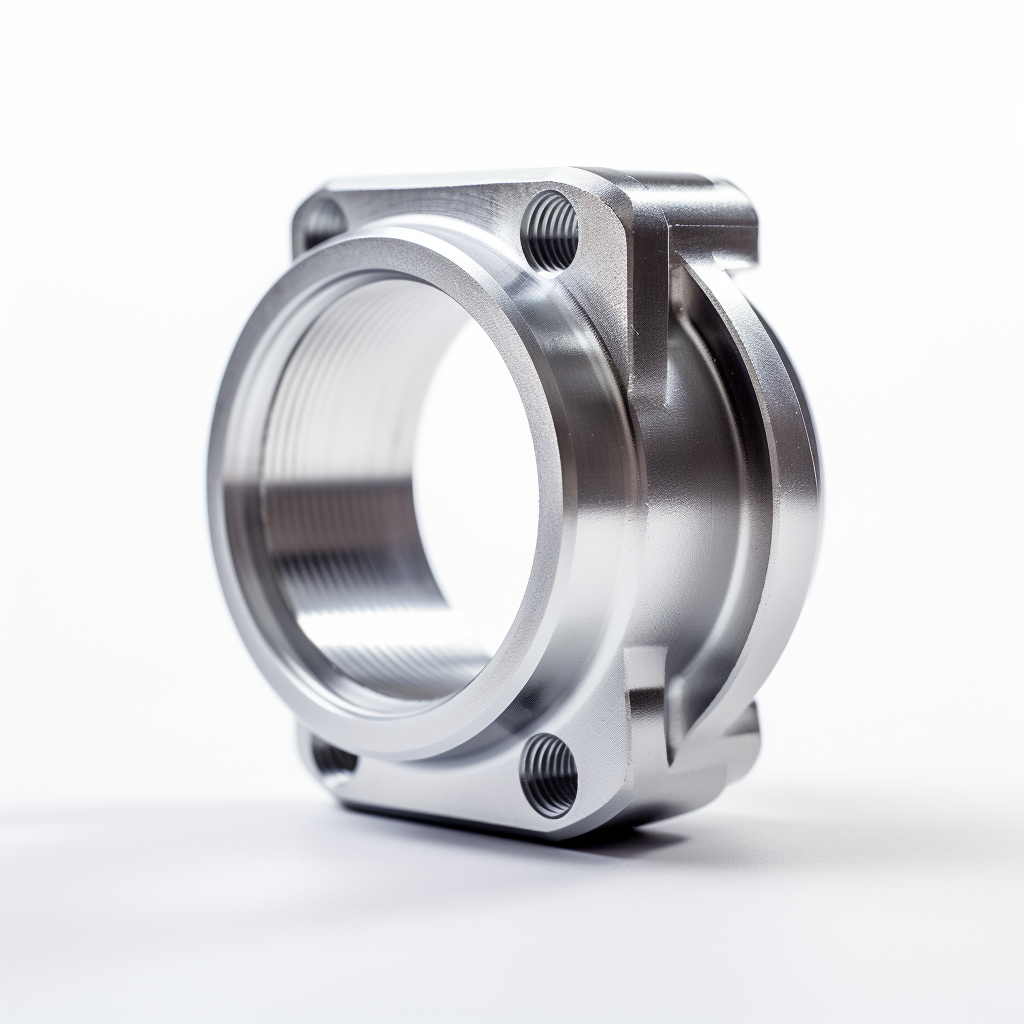

Custom Metal Parts

Custom metal parts are essential components in a wide range of industries, providing tailored solutions for specific applications. From aerospace and automotive to medical and industrial manufacturing, custom metal parts offer durability, precision, and performance. By utilizing advanced manufacturing techniques and a variety of materials, custom metal parts can be designed and produced to meet the exact specifications required for complex projects.

Custom manufactured metal parts with overmolded silicone, CanRez® FFKM and Kalrez® gaskets, rapid manufacturing, & custom molded parts are available now!

Check with one of Canyon’s helpful product engineers for an expert material and manufacturing recommendation.

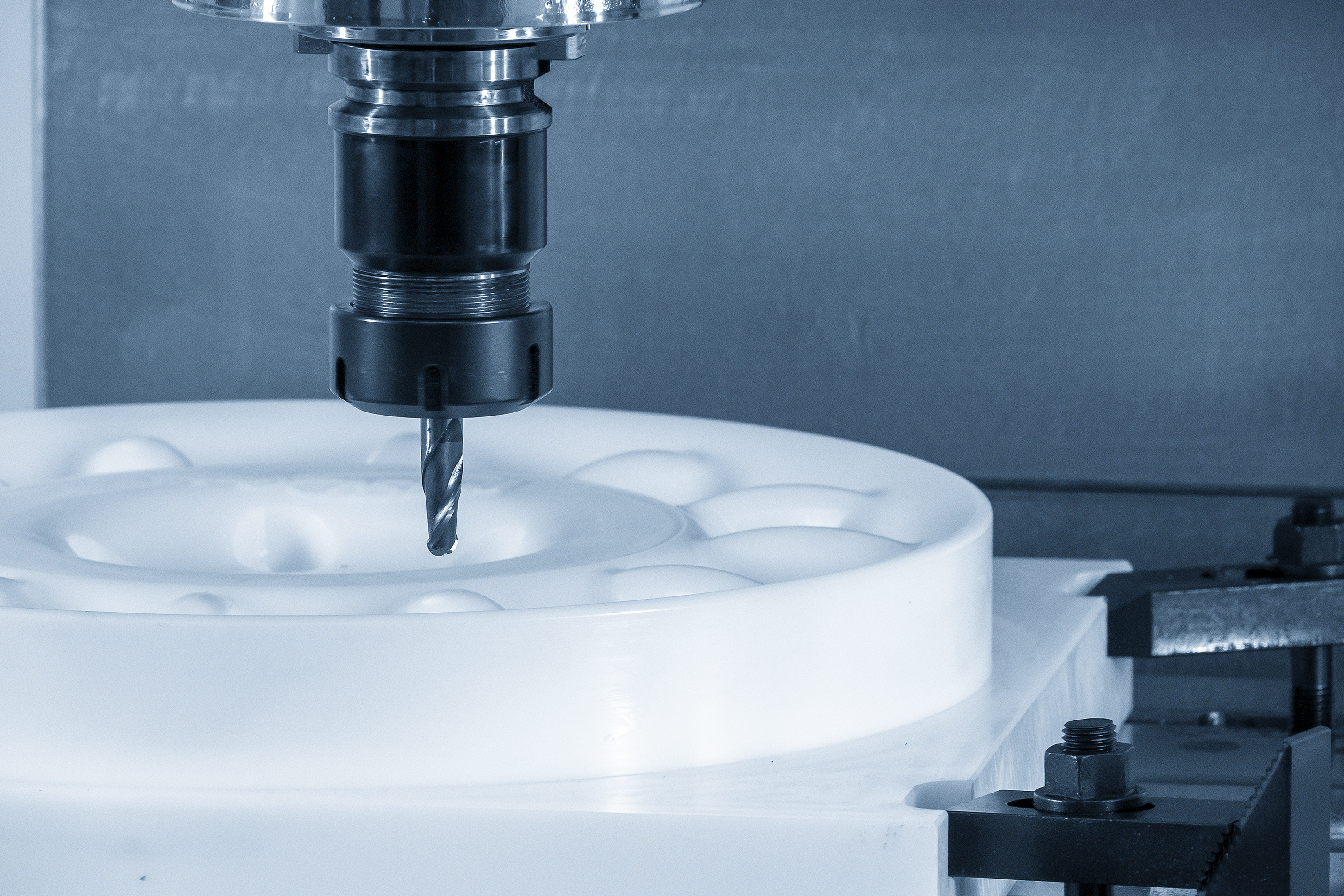

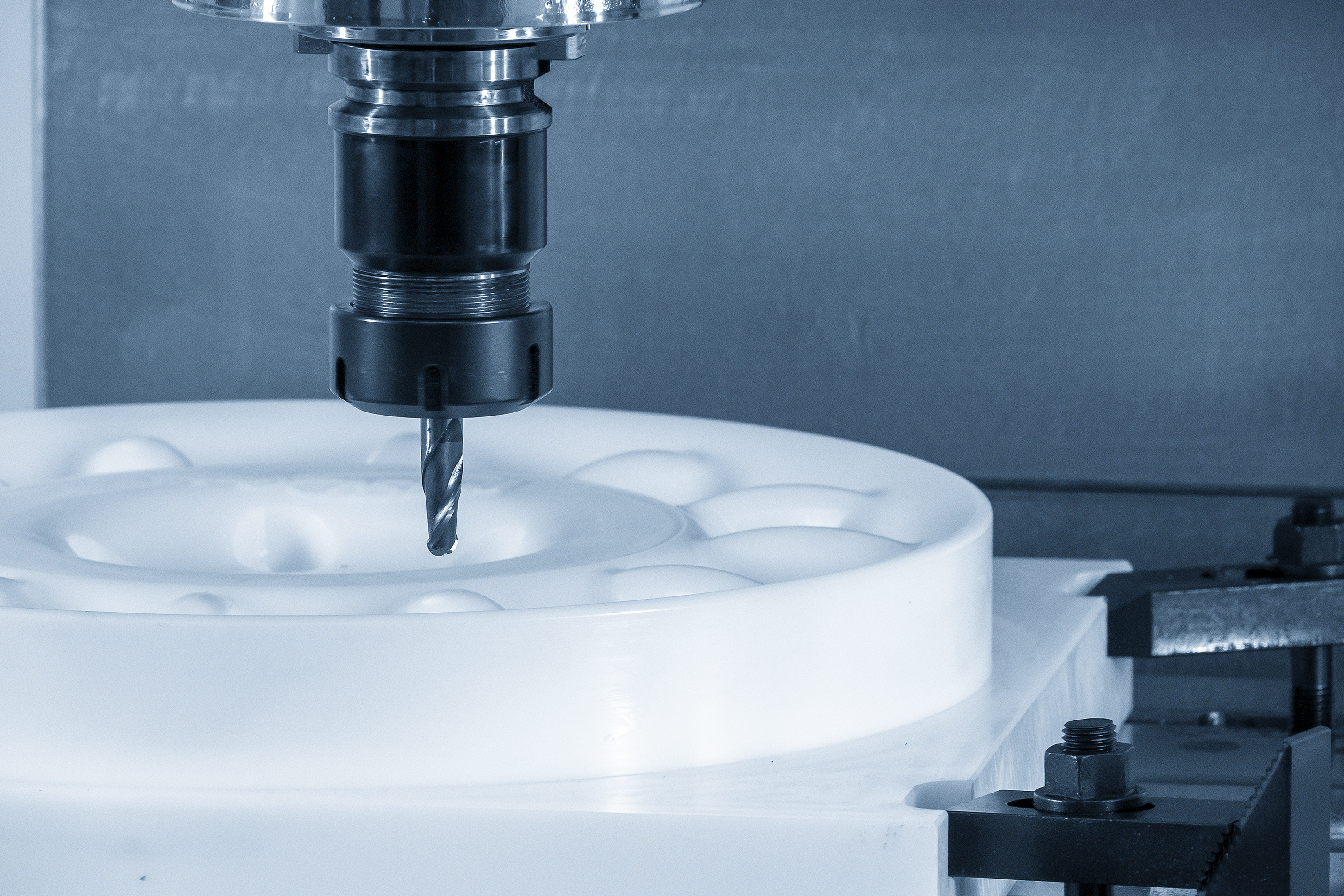

Manufacturing Types for Custom Metal Parts

There are several manufacturing methods used to produce custom metal parts, each offering unique advantages depending on the application and material requirements:

- CNC Machining: CNC (Computer Numerical Control) machining is a precise manufacturing process used to create complex parts from metal blocks. This method offers high accuracy and is ideal for small-to-medium production runs or prototyping.

- Metal Stamping: Metal stamping uses a press and dies to shape or cut metal sheets into the desired part. It is suitable for high-volume production, offering cost efficiency for parts that require repetitive designs.

- Casting: Casting involves pouring molten metal into a mold to create complex shapes. There are different casting methods, including sand casting, die casting, and investment casting, each suitable for different levels of complexity and production scale.

- Laser Cutting: Laser cutting uses a focused laser beam to cut metals with extreme precision. This method is often used for intricate designs or when sharp edges and fine details are required.

- Metal 3D Printing (Additive Manufacturing): Metal 3D printing creates parts layer by layer using powdered metal. This technology is growing rapidly, offering design flexibility and cost savings for low-volume production and prototyping.

Common Types of Custom Metal Parts

Custom metal parts vary based on industry requirements and the intended application. Some of the most common types include:

- Brackets and Mounting Hardware: Used to support, mount, or connect various components in machines, vehicles, or structural assemblies.

- Gears and Precision Components: Gears, bearings, and shafts used in mechanical systems require high precision and durability to ensure smooth operation.

- Enclosures and Housings: Custom metal enclosures are used to protect sensitive electronics, electrical components, or mechanical systems from environmental factors.

- Fasteners and Connectors: Metal fasteners like bolts, nuts, screws, and rivets are critical for assembly and maintenance in almost every industry.

- Heat Sinks and Cooling Components: In electronics and electrical systems, metal heat sinks are used to dissipate heat and maintain optimal operating temperatures.

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

Get a Quote Now!

Materials

Steel

Steel is a strong, durable alloy primarily made from iron and carbon. It's characterized by its high tensile strength and resistance to corrosion and wear. Steel often contains additional elements like chromium, nickel, and manganese to enhance its properties.

Carbon Steel

Carbon steel, a robust alloy of iron and carbon, is distinguished by its impressive tensile strength, hardness, and ability to be magnetized. Predominantly used in construction and manufacturing, it features a silver-gray appearance and excels in durability and wear resistance.

Alloy Steel

Alloy steel is a robust metal composed of iron mixed with various elements like chromium, nickel, molybdenum, and vanadium. This combination enhances properties such as strength, hardness, durability, and corrosion resistance, making it ideal for diverse industrial applications.

Stainless Steel

Stainless steel, an alloy of iron, chromium, and often nickel, is renowned for its corrosion resistance and lustrous appearance. Its durability, easy maintenance, and hygienic qualities make it a popular choice in kitchenware, medical equipment, and architectural structures.

Aluminum

Aluminum, a lightweight, silver-white metal, is known for its remarkable corrosion resistance and high strength-to-weight ratio. It's easily machinable, conducts heat and electricity well, and is widely used in aerospace, transportation, and packaging industries due to its versatility.

Brass

Brass is a versatile alloy primarily composed of copper and zinc, known for its golden-yellow hue. It exhibits excellent malleability, acoustic properties, and resistance to corrosion, making it a popular choice for musical instruments, decorative items, and various fittings.

Bronze

Bronze, a copper-tin alloy, often contains small amounts of other elements like aluminum or nickel. It's known for its hardness, durability, and distinctive reddish-brown color. Widely used in sculpture, coins, and industrial applications, bronze resists corrosion and metal fatigue.

Copper

Copper is a reddish-brown, highly ductile and conductive metal, renowned for its thermal and electrical conductivity. It's naturally antimicrobial and corrosion-resistant, extensively used in electrical wiring, plumbing, coinage, and as a component in various metal alloys.

Iron

Iron is a lustrous, ductile, malleable metal with a silvery-gray appearance. As a fundamental building block of modern industry, it is magnetic, has high melting and boiling points, and forms compounds with various elements, prominently influencing Earth's geology and human technology.

Magnesium Alloy

Magnesium alloy, a lightweight and strong metal, is characterized by its low density, high strength-to-weight ratio, and excellent machinability. It's often used in aerospace, automotive industries, and electronics for its weight-saving benefits and ability to dissipate heat effectively.

Nickel Alloy

Nickel alloy, a blend of nickel and other elements, is known for its exceptional corrosion resistance, heat resistance, and strength. It excels in harsh environments, making it ideal for aerospace, chemical processing, and power generation applications. Its silvery-white appearance adds to its appeal.

Titanium

Titanium is a lightweight, strong metal with a silvery-white appearance, known for its exceptional corrosion resistance and high strength-to-density ratio. Widely used in aerospace, medical implants, and sporting equipment, it forms alloys with elements like aluminum and vanadium.

Tungsten Carbide

Tungsten carbide, a composite of tungsten and carbon, is exceptionally hard and wear-resistant. It has a high melting point and great rigidity, making it ideal for cutting tools, abrasives, and armor-piercing rounds. Its density and strength are comparable to those of diamond.

Zinc Alloy

Zinc alloy is a robust metal combination mainly composed of zinc, often blended with aluminum, copper, and magnesium. It's known for its high strength, good corrosion resistance, and ability to be cast into intricate shapes, commonly used in die-casting and automotive parts.

Back to Custom Parts

Custom Metal Parts Pros & Cons

Custom metal parts are essential for industries requiring precision, strength, and durability in their components. With various manufacturing methods available—such as CNC machining, metal stamping, die casting, and more—there is a solution for nearly every application. By understanding the manufacturing types, common metal part types, and the pros and cons of each approach, you can make informed decisions that ensure the best performance and cost-effectiveness for your custom metal part needs.

Canyon Components strives to meet all customer service requests. Feel free to contact Canyon Components engineering and let our knowledgeable staff help you design the perfect part for your needs.

Pros of Custom Metal Parts

Custom metal parts offer a variety of benefits, making them essential for a wide range of applications:

- Tailored to Specifications: Custom metal parts are designed to meet exact specifications, ensuring a perfect fit for unique applications.

- Durability and Strength: Metal parts are highly durable and can withstand extreme temperatures, pressures, and harsh environmental conditions, making them ideal for long-term use in demanding applications.

- Versatility in Design: With advanced manufacturing techniques, custom metal parts can be made in complex shapes, sizes, and finishes to suit diverse needs.

- Cost-Effective for Large Runs: Custom metal parts become more cost-effective as production volumes increase, especially when using processes like stamping or die casting.

Cons of Custom Metal Parts

While custom metal parts provide numerous advantages, there are a few challenges and limitations to consider:

- High Initial Costs: The design, tooling, and setup costs for manufacturing custom metal parts can be high, particularly for CNC machining, die casting, or stamping.

- Lead Time for Tooling: Some manufacturing processes, such as die casting and metal stamping, require specialized tooling that can take time to develop, leading to longer lead times before production can begin.

- Material Limitations: Not all manufacturing processes can accommodate all metals, which may limit material choices based on the process used.

Other Custom Products

Custom Parts

Whether your O-rings, gaskets, & custom molded parts be rubber, plastic, or metal, rest assured that Canyon Components can make it!

Custom Plastic Parts

Discover custom plastic parts designed for your unique specifications. Learn about our advanced manufacturing processes, material options, and how we provide reliable, high-quality plastic components for various industries.

Custom Rubber Parts

Explore custom rubber parts tailored to your exact specifications. Learn about our material options, manufacturing processes, and how we deliver durable and reliable rubber components for various industries.

Back to Custom Parts

Get A Quote Now!