Elastomer Tubing: Features, Applications, and Material Options

Elastomer tubing is a versatile and flexible solution used in various industries to transport fluids, gases, and other materials. Made from rubber-like materials, elastomer tubing offers excellent flexibility, chemical resistance, and durability, making it ideal for a wide range of applications. This guide covers the features, common applications, and the pros and cons of elastomer tubing.

Silicone, Fluorosilicone, Viton, CanRez® FFKM and Kalrez® tubing, O-rings, micro gasket rapid manufacturing, & custom molded parts are available now!

Check with one of Canyon’s helpful product engineers for an expert material and manufacturing recommendation.

Features of Elastomer Tubing

Elastomer tubing offers several key features that make it suitable for diverse applications:

- Flexibility: Elastomer tubing is highly flexible, allowing it to be used in tight spaces and complex routing paths without kinking or collapsing.

- Chemical Resistance: Depending on the material, elastomer tubing can resist a wide range of chemicals, making it suitable for harsh environments and chemical processing.

- Temperature Range: Elastomer tubing can be designed to withstand extreme temperatures, from very low to high, ensuring reliable performance in various conditions.

- Durability: Built to withstand abrasion, wear, and repeated use, elastomer tubing offers long-lasting performance even in demanding applications.

- Non-Toxic and Biocompatible: Some elastomer tubing materials, such as silicone, are non-toxic and biocompatible, making them safe for use in medical and food-related applications.

Common Applications of Elastomer Tubing

Elastomer tubing is used in a wide range of industries due to its versatility and reliability. Common applications include:

- Medical and Pharmaceutical: Elastomer tubing is used in medical devices, fluid delivery systems, and pharmaceutical processing, where hygiene, flexibility, and chemical resistance are critical.

- Food and Beverage: In food and beverage processing, elastomer tubing is used to transport liquids, gases, and other materials, ensuring safe and contamination-free operations.

- Automotive: Elastomer tubing is found in automotive systems such as fuel lines, coolant hoses, and vacuum lines, where flexibility and chemical resistance are essential.

- Industrial: In industrial applications, elastomer tubing is used to transport chemicals, gases, and fluids in processes such as chemical manufacturing, oil and gas production, and wastewater treatment.

- HVAC Systems: Elastomer tubing is used in heating, ventilation, and air conditioning systems to transport refrigerants, air, and other fluids.

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

Get a Quote Now!

Elastomer Tubing Materials

CanRez® FFKM Perfluoroelastomer

Extreme temperatures & chemicals require extreme solutions! CanRez® FFKM tubing and materials offer extreme reliability where you need it most! Thousands of sizes in stock now!

CanGuard™ RFI & EMI Shielding Materials

CanGuard™ materials have been developed to offer superior sealing solutions with enhanced electromagnetic interference (EMI) shielding and radio frequency interference (RFI) shielding in a tubing format.

Kalrez® FFKM Perfluoroelastomer

Canyon Components offers Kalrez® Perfluoroelastomer (FFKM) tubing, gaskets, & custom molded parts at competitive prices and with great lead-times.

Parker® O-rings, Parofluor parts, parker FKM Viton

Canyon Components offers Parker Hannifin® tubing, Gaskets, Perfluoroelastomer (FFKM) parts, & custom molded parts at competitive prices and with great lead-times.

FKM (Viton®, Fluorocarbon)

FKM tubing, diaphragms, & custom molded parts exhibit excellent mechanical attributes as well as excellent resistance to high temperatures, mineral oil, ozone, fuels, hydraulic fluids, and many other solvents and chemicals.

Silicone (VMQ, PVMQ)

Silicone tubing, seals, micro O-rings, gaskets, & custom molded parts are excellent for extreme temperatures in static applications. Canyon Components carries a range of silicone materials, and we are happy to custom tailor a seal to meet your application requirements!

Fluorosilicone (FVMQ)

The mechanical and physical properties of Fluorosilicone tubing, gaskets, & custom molded parts are very similar to silicone. Fluorosilicone O-rings, gaskets, & custom molded parts offer improved flexibility and strength, better resistance to fuels and mineral oil, but reduced hot air resistance.

Aflas® (TFE/P)

TFE/P (Aflas) tubing, compounds, micro O-rings, gaskets, & custom molded parts gives high resistance to steam, hot water, atmospheric wear, and many chemicals. TFE/P compounds provide superior performance in water, steam and virtually all caustic chemicals.

EPDM (Ethylene Propylene)

EPDM tubing, materials, micro O-rings, gaskets, & custom molded parts can operate over a wide temperature range, and are compatible with glycol fluids that cause problems for most typical elastomeric seals.

NBR (Nitrile, Buna-N)

Nitrile tubing, micro O-rings, gaskets, & custom molded parts are very oil-resistant, have strong mechanical properties, are resistant to wear, and are relatively inexpensive. These properties make Nitrile the most commonly used general purpose O-ring, gasket, & custom molded part material.

HNBR (Hydrogenated Nitrile)

Hydrogenated Nitrile tubing, micro O-rings, gaskets, & custom molded parts offer higher strength and reduced degradation at high temperatures compared to conventional Nitrile materials. These properties make HNBR materials popular in the oil and gas industry, as well as many applications in the chemical industry.

XNBR (Carboxylated Nitrile)

XNBR tubing, micro O-rings, gaskets, & custom molded parts are similar to Nitrile, but the backbone has been chemically modified with a Carboxylic Acid group. The resulting elastomer is a Nitrile rubber with outstanding abrasion and chemical resistance, superior to that of traditional Nitrile.

Neoprene (CR)

Chloroprene was the first synthetic rubber, and was developed commercially under the name Neoprene®. Chloroprene tubing, rubbers, micro O-rings, gaskets, & custom molded parts contain Chlorine in the polymer to reduce the reactivity to many oxidizing agents, as well as to oil and flame.

Polyurethane (PU, AU)

Polyurethane tubing, micro O-rings, gaskets, & custom molded parts generally have two or three times greater tensile strength and wear resistance than Nitrile and comparable polymers. Polyurethane also provides excellent permeation resistance when compared to most rubbers.

PTFE (Teflon)

The harshest environments require specialized solutions. Often times, a Canyon Components PTFE tubing is used in harsh chemical environments. Polytetrafluoroethylene, commonly known as PTFE or Teflon®, is a high-performance fluoropolymer known for its exceptional chemical resistance, low friction, and non-stick properties.

Product Types

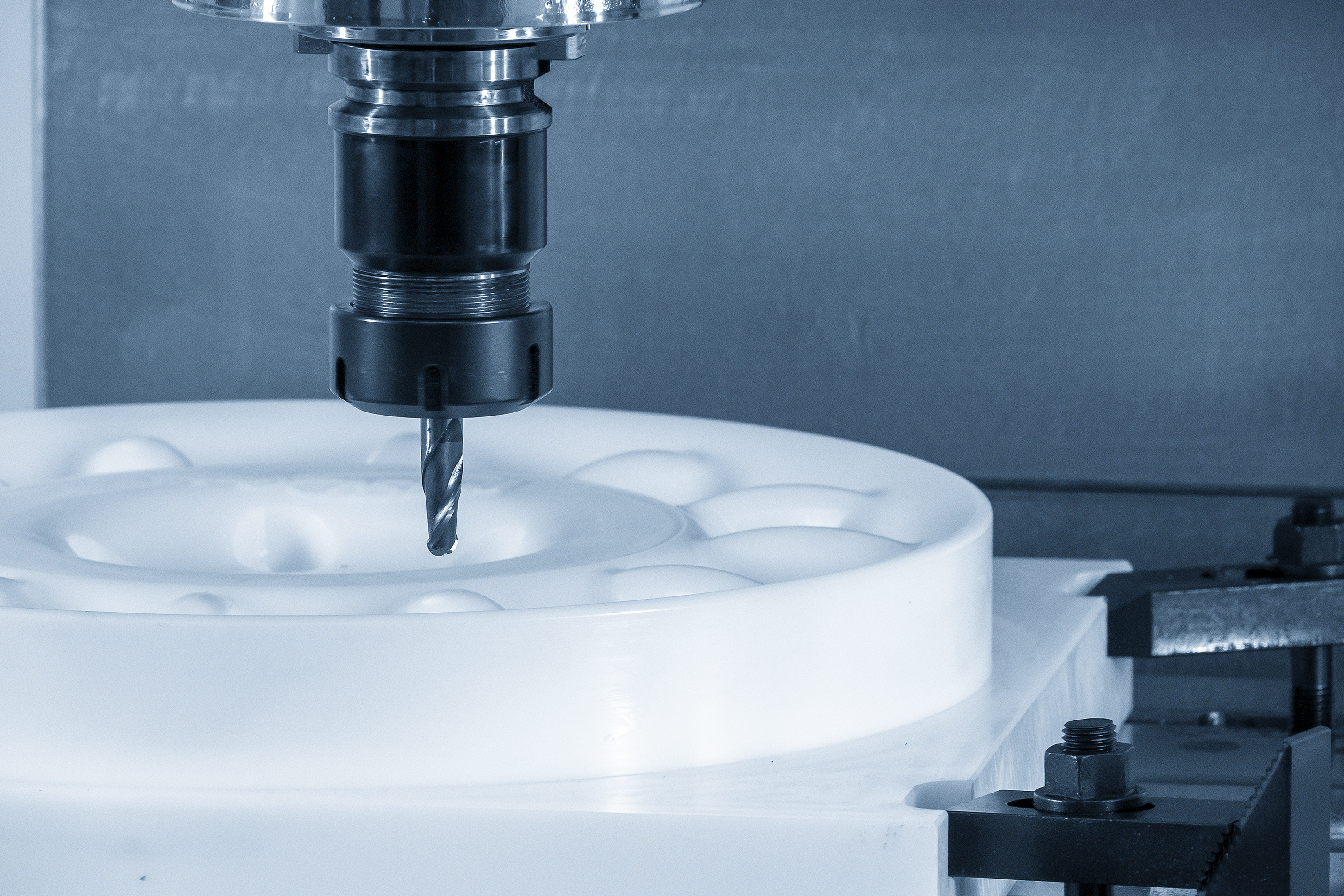

Custom Parts

Here at Canyon Components, we make sure to offer our customers any manufacturing technique they desire. Whether your tubing, gaskets, & custom molded parts be rubber, plastic, or metal, rest assured that Canyon Components can make it!

Gaskets & Custom Cutting

Whether your custom cut parts be rubber, plastic, sponge, composite, or metal, rest assured that Canyon Components can make it! Canyon Components strives to meet all customer service requests. If you need something that isn't listed, feel free to contact a Canyon Components product and application consultant.

Specialty Compliances

Canyon have materials available for tubing, gaskets, & custom parts with compliances ranging from USP Class VI <87> & <88> for medical applications, to FDA CFR 21.177.2600 grades A through F for different food types, to the various drinking water specifications like KTW and NSF. Whether it's metal, rubber, or plastic, Canyon can meet your needs!

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

Elastomer Tubing Pros & Cons

Elastomer tubing is a versatile and reliable solution for transporting fluids, gases, and other materials across a wide range of industries. Its flexibility, chemical resistance, and durability make it ideal for applications from medical devices to industrial processes. However, potential limitations in cost, pressure tolerance, and material longevity should be considered when selecting elastomer tubing for specific applications. Understanding the features, applications, and potential drawbacks of elastomer tubing will help you make informed decisions to ensure optimal performance in your systems.

Canyon Components strives to meet all customer service requests. Feel free to contact Canyon Components engineering and let our knowledgeable staff help you design the perfect part for your needs.

Pros of Elastomer Tubing

Elastomer tubing offers several advantages that make it a preferred choice in many applications:

- Versatility: With a wide range of materials available, elastomer tubing can be tailored to meet specific chemical, temperature, and pressure requirements.

- Flexibility: Elastomer tubing's flexibility allows it to be easily installed in complex systems without compromising performance.

- Durability: Elastomer tubing is built to last, offering resistance to wear, abrasion, and environmental factors, leading to long service life.

- Chemical Resistance: Depending on the material, elastomer tubing can resist various chemicals, making it suitable for harsh environments.

- Non-Toxic Options: Some elastomer materials, like silicone, offer non-toxic and biocompatible options for medical and food applications.

Cons of Elastomer Tubing

While elastomer tubing offers many benefits, there are also some potential drawbacks to consider:

- Cost: High-quality elastomer tubing, especially those with specialized properties like high chemical resistance or biocompatibility, can be more expensive than standard tubing options.

- Limited Pressure Tolerance: While elastomer tubing is durable, it may not be suitable for high-pressure applications where rigid tubing or metal pipes are required.

- Material Degradation: Depending on the environment and chemicals involved, elastomer tubing may degrade over time, leading to reduced performance or the need for replacement.

- Permeability: Some elastomer materials may allow certain gases or fluids to permeate through the tubing walls, which could be a concern in specific applications.

Back to Products Hub

Get A Quote Now!