Gaskets and Custom Cut Parts

Gaskets and custom cut parts are essential components in various industries, providing critical sealing, insulation, and cushioning functions. These parts are tailored to meet specific application needs, ensuring that machinery and equipment operate efficiently and reliably. This guide covers the types, features, common applications, and the pros and cons of gaskets and custom cut parts.

CanRez® FFKM and Kalrez® O-rings, gasket rapid manufacturing, & custom molded parts are available now!

Check with one of Canyon’s helpful product engineers for an expert material and manufacturing recommendation.

Features of Gaskets and Custom Cut Parts

Gaskets and custom cut parts are designed with specific features that ensure reliable performance in various applications:

- Precision Cutting: Gaskets and custom parts are precisely cut to match the exact specifications required for each application, ensuring a perfect fit and effective sealing.

- Material Versatility: Available in a wide range of materials, including rubber, metal, plastic, foam, and composites, these parts can be tailored to meet the chemical, thermal, and mechanical requirements of different applications.

- Custom Shapes and Sizes: With advanced cutting technologies, gaskets and custom parts can be produced in virtually any shape or size, meeting the unique needs of each project.

- Durability: Designed to withstand harsh environments, gaskets and custom cut parts offer long-lasting performance, even under extreme conditions.

- Compliance with Standards: Many gaskets and custom cut parts are manufactured to meet industry standards, such as ASTM, ISO, or FDA, ensuring they are suitable for use in regulated industries.

Common Applications of Gaskets and Custom Cut Parts

Gaskets and custom cut parts are used in a wide range of industries and applications:

- Automotive: In the automotive industry, gaskets are used to seal engines, transmissions, exhaust systems, and other components, preventing leaks and ensuring efficient operation.

- Aerospace: Aerospace applications require gaskets that can withstand extreme temperatures, pressures, and vibrations, making custom cut parts essential for sealing and insulating critical components.

- Industrial Machinery: Gaskets and custom cut parts are used in industrial machinery to seal joints, prevent leaks, and provide cushioning and insulation in pumps, valves, and compressors.

- HVAC Systems: Gaskets are used in heating, ventilation, and air conditioning systems to seal ductwork, prevent air leaks, and improve energy efficiency.

- Electronics: In electronics, custom cut parts are used for insulation, sealing, and vibration damping, ensuring the reliability and longevity of sensitive components.

- Food and Beverage: Gaskets and custom parts made from food-grade materials are used in processing and packaging equipment to ensure product safety and hygiene.

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

Get a Quote Now!

Gasket & Cutting Materials

Branded

- Armstrong

- Cogibi

- Durlon

- Envalon

- Fairprene

- Fiberfrax

- Flexitallic

- Garlock

- Grafoil

- Klinger

- Taskline

- TEADIT

- Vellumoid

- Victor Reinz

Composites

- Aramid Fiber / EPDM

- Aramid Fiber / Hypalon

- Aramid Fiber / NBR

- Aramid Fiber / Neoprene

- Aramid Fiber / SBR

- Arimid Fiber / Wire

- Carbon Fiber / NBR

- Carbon Fiber / SBR

- Carbon Fiber Composite

- Cloth Inserted 1,2 And 4 Ply

- Composition Cork

- Cork & Rubber

- Ecor

- Fiber Cork

- GHE

- GHL

- GHR

- Grafoil With Tang Insert

- Inorganic Fiber

- Laminated Grafoil

- Layered Grafoil

- Mica

- Nicote

- Nuclear Grade Grafoil

- Phenolic

- Rubberized Fiberglass

- Thermiculite

- Thermoseal

- Vegetable Fiber

- Velbuna

Elastomer

- Aflas®

- Buna-N

- Buna-S

- Butyl

- CanRez FFKM

- Chemraz® FFKM

- Corrugated Matting

- EPDM

- FFKM

- Hypalon

- FKM

- Kalrez® FFKM

- Matting

- Neoprene

- Nitrile

- Polyurethane

- Pure Gum

- Silicone

- Viton ETP

- Viton F

- Viton GF

- Viton GLT

- Viton ETP

- Viton

- Viton B

- Viton Extreme

Metal

- Aluminum

- Brass

- Bronze

- Carbon Steel

- Copper

- Metal Alloys

- Stainless Steel

- Stainless Steel Mesh

- Titanium

- Tool Steel

Plastic

Specification

- FDA Compliant

- Non-Asbestos

- NSF 51 & NSF 61

- USP Class VI

- AED Norsok M710

- AED NACE TM0297

- KTW

- WRAS

- 3A Sanitary

- Clean Room Manufactured

Sponge

- Closed Cell Sponge

- EVA Sponge

- Open Cell Sponge

Textile & Paper

- 550-K Ceramic Fiber

- 970-J Ceramic Fiber

- 970-L Ceramic Fiber

- CN-705

- Ceramic Fiber

- Carbon Fiber

- Felt

- Fiberglass Cloth

- Fiberglass Cloth / Wire

- Kevlar

- Tetra Glass

Product Types

Custom Parts

Here at Canyon Components, we make sure to offer our customers any manufacturing technique they desire. Whether your O-rings, gaskets, & custom molded parts be rubber, plastic, or metal, rest assured that Canyon Components can make it!

Infinite "Giant" Diameter O-Rings

By either Continuous Molding O-rings, or Splice & Vulcanizing O-rings, Canyon can provide mold-less, infinitely large O-rings at competitive prices!

Specialty Compliances

Canyon have materials available for O-rings, gaskets, & custom parts with compliances ranging from USP Class VI <87> & <88> for medical applications, to FDA CFR 21.177.2600 grades A through F for different food types, to the various drinking water specifications like KTW and NSF. Whether it's metal, rubber, or plastic, Canyon can meet your needs!

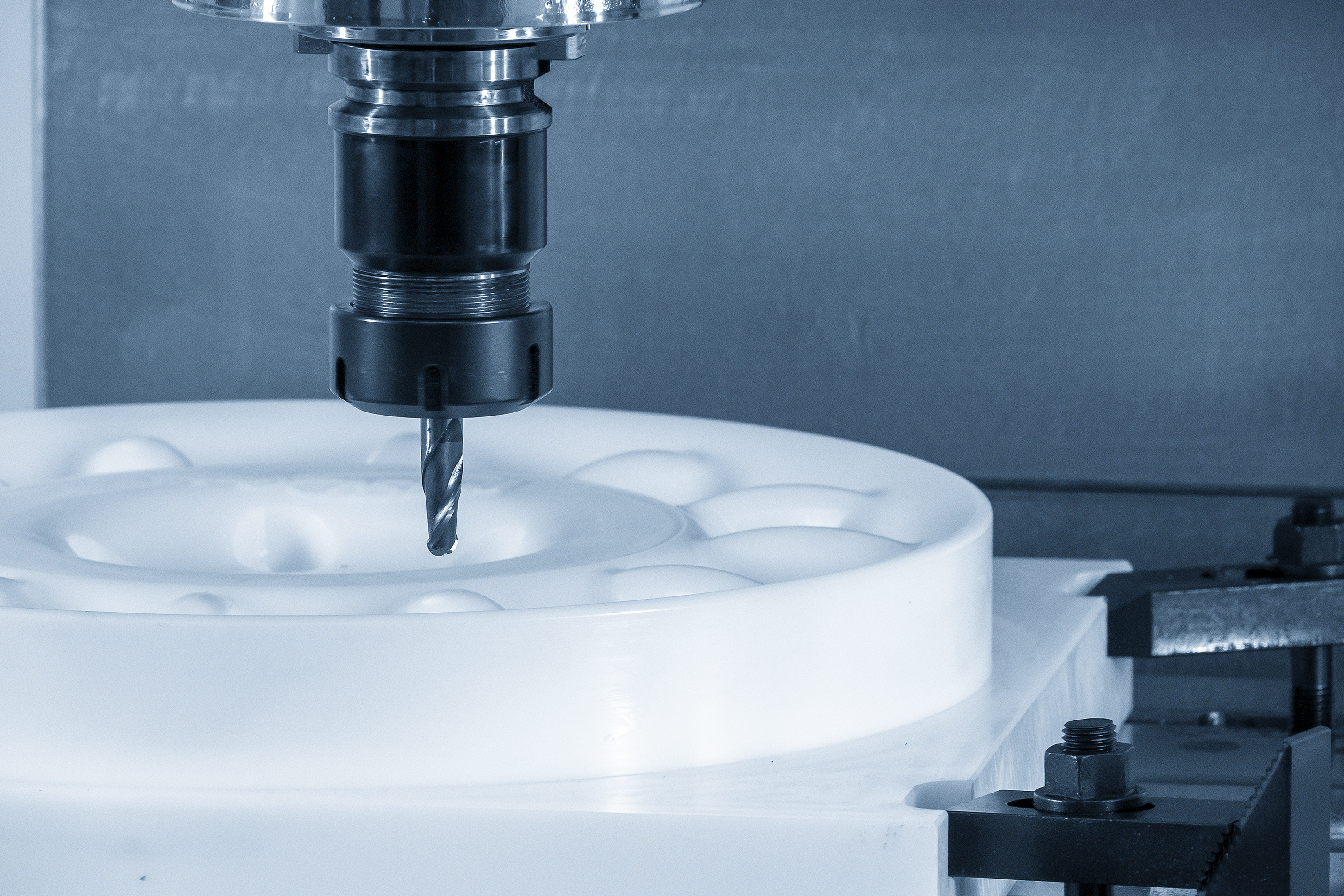

Manufacturing Methods

Depending on the part being produced, there are a number of ways that we can approach the production of a cut gasket or cut component. Cutting methods include CNC Knife Cutting, CNC Laser Cutting, CNC Water Jet Cutting, or Flat Bed Die Cutting. Availability of specific cutting methods may vary depending on the material being cut.

For additional information, see our blog post on cut gaskets and cut parts. Also, Canyon Components engineers are also available to assist in part design and in consultation.

Canyon Components strives to meet all customer service requests. Feel free to contact Canyon Components engineering and let our knowledgeable staff help you design the perfect part for your needs.

Types of Gaskets and Custom Cut Parts

Gaskets and custom cut parts come in various types, each designed to address specific requirements:

- Flat Gaskets: These gaskets are typically cut from sheet materials and provide sealing between two flat surfaces. They are commonly used in flange connections and other static sealing applications.

- Ring Gaskets: Designed to fit around circular or cylindrical components, ring gaskets are used in applications where a seal is required around a specific area, such as pipes or shafts.

- Die-Cut Parts: Custom cut parts produced using die-cutting processes, which allow for precision and repeatability in creating parts with complex shapes.

- Rubber Gaskets: These gaskets are made from various rubber materials, such as EPDM, Nitrile, Silicone, and Viton, offering flexibility, chemical resistance, and durability.

- Metal Gaskets: Used in high-temperature and high-pressure applications, metal gaskets provide robust sealing where other materials might fail.

- Composite Gaskets: These gaskets combine different materials, such as rubber and metal, to provide enhanced sealing performance and resistance to specific environmental conditions.

Canyon Components strives to meet all customer service requests. Feel free to contact Canyon Components engineering and let our knowledgeable staff help you design the perfect part for your needs.

Gasket and Cut Part Pros & Cons

Gaskets and custom cut parts are vital components in many industries, providing essential sealing, insulation, and protection functions. With a wide range of materials and customization options available, these parts can be tailored to meet the specific needs of any application, ensuring reliable performance and cost-effective solutions. Understanding the types, features, applications, and potential drawbacks of gaskets and custom cut parts will help you make informed decisions to ensure optimal performance in your systems.

Canyon Components strives to meet all customer service requests. Feel free to contact Canyon Components engineering and let our knowledgeable staff help you design the perfect part for your needs.

Pros of Gaskets and Custom Cut Parts

Gaskets and custom cut parts offer several advantages that make them essential in various applications:

- Customizability: These parts can be tailored to meet specific requirements, ensuring optimal performance in any application.

- Wide Material Selection: With a broad range of materials available, gaskets and custom parts can be selected to match the environmental, chemical, and mechanical demands of the application.

- Improved Efficiency: By providing effective sealing, insulation, and cushioning, gaskets and custom cut parts help improve the efficiency and reliability of machinery and equipment.

- Cost-Effective: Custom cut parts offer a cost-effective solution for sealing and insulation, reducing the need for expensive repairs and maintenance.

- Enhanced Performance: Customization allows for the design of parts that enhance the performance of the system, whether through improved sealing, reduced vibration, or better thermal management.

Cons of Gaskets and Custom Cut Parts

While gaskets and custom cut parts offer many benefits, there are also some potential drawbacks to consider:

- Material Limitations: The performance of gaskets and custom parts is highly dependent on the material used. Selecting the wrong material can lead to premature failure or reduced effectiveness.

- Complexity in Design: Custom cut parts require precise design and manufacturing, which can increase the complexity and cost of the production process.

- Maintenance Requirements: Some gaskets, especially those in dynamic applications, may require regular maintenance and replacement to ensure continued performance.

- Lead Times: Depending on the complexity and customization required, the lead time for producing gaskets and custom cut parts may be longer than for standard off-the-shelf components.

Back to Products Hub

Get A Quote Now!