Casting

Casting manufacturing is a versatile process that involves pouring a molten material into a mold to create a desired shape as it solidifies. It is one of the oldest and most widely used manufacturing techniques, offering a wide range of possibilities for producing complex parts and components. In this web page, we will explore the different types of casting, their advantages and disadvantages, and the diverse industrial applications. Additionally, we'll provide a list of materials commonly used in casting manufacturing. Custom Casted parts available now!

Check with one of Canyon’s helpful product engineers for an expert material and manufacturing recommendation.

Common terminology includes: Sand casting, investment casting, die casting, lost wax casting, centrifugal casting, permanent mold casting, gravity die casting, low pressure casting, shell mold casting, plaster casting, vacuum casting, squeeze casting, lost foam casting.

Advantages

- Versatility: Suitable for a wide range of materials, sizes, and shapes.

- Complex Geometries: Allows for the production of intricate and detailed parts.

- Cost-Effective: Economical for large production runs and low tooling costs.

- Material Efficiency: Minimizes waste as excess material can be reused.

- Design Flexibility: Easily adapts to design changes and prototypes.

Disadvantages

- Surface Finish: Achieving a smooth surface may require additional processing steps.

- Dimensional Accuracy: Precision varies depending on the casting method.

- Setup Time: Initial tooling and mold preparation can be time-consuming.

Common Applications of Casting

- Automotive: Producing engine blocks, transmission housings, and wheels.

- Aerospace: Manufacturing aircraft components, engine parts, and turbine blades.

- Jewelry: Creating intricate and detailed jewelry pieces using investment casting.

- Construction: Casting architectural components, decorative hardware, and fittings.

- Energy: Fabricating turbine components, heat exchangers, and pipes.

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

Types of Casting

Casting can be performed in a number of ways depending on the composition and intended use of the final product. Some variations available for Casting include the following.

Canyon Components strives to meet all customer service requests. Feel free to contact Canyon Components engineering and let our knowledgeable staff help you design the perfect part for your needs.

Sand Casting

Involves pouring molten metal into a sand mold cavity. It's versatile for various metals and sizes, and cost-effective for small batches. The downside is the rough surface finish and lower accuracy, requiring more post-processing.

Investment Casting

Uses a wax pattern covered in refractory material to create molds. It offers high precision and excellent surface finish. However, it’s more expensive and time-consuming, making it less suitable for large-scale production.

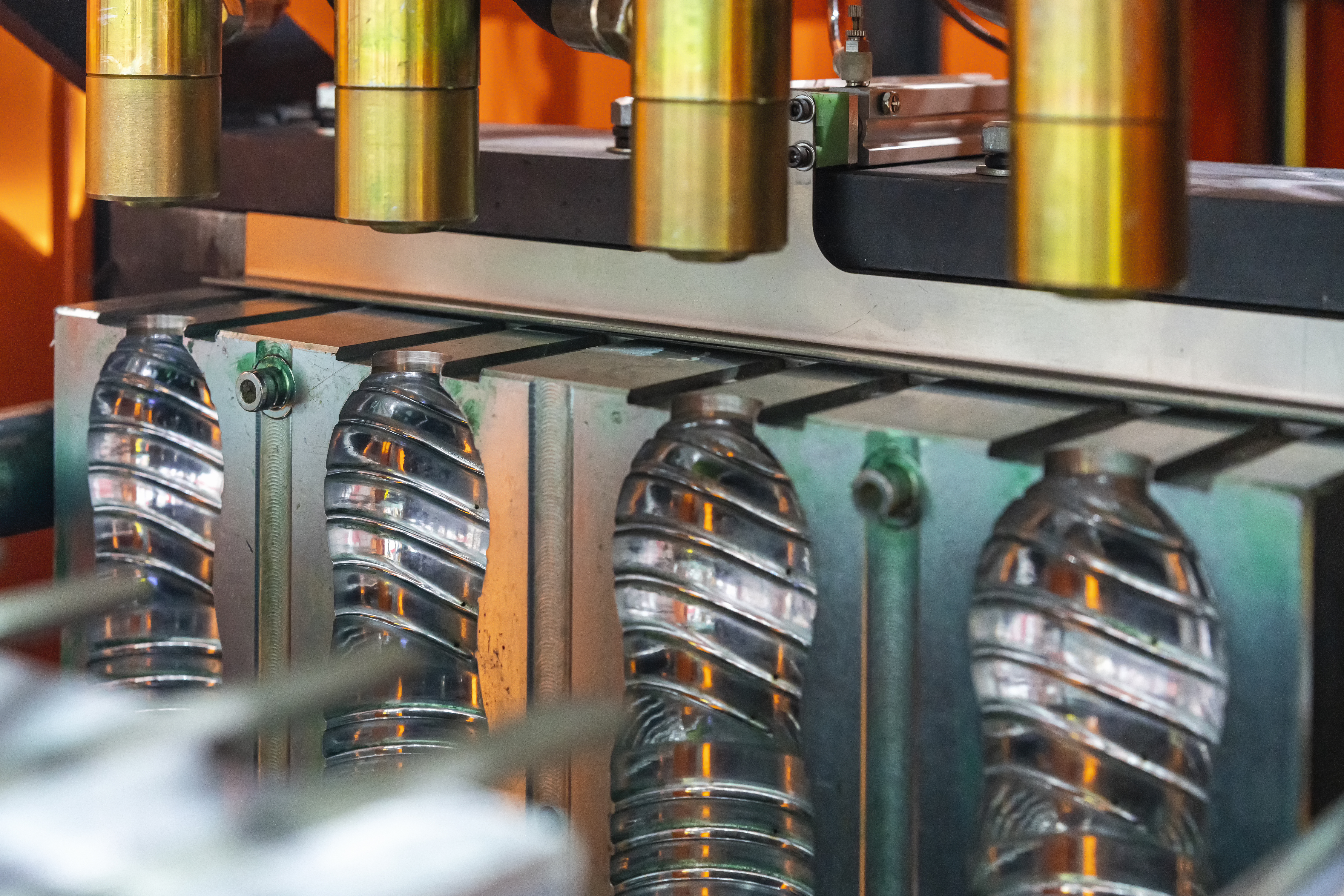

Die Casting

Involves injecting molten metal into a reusable metal mold under high pressure. Ideal for high-volume production of complex, detailed parts. The advantage is speed and repeatability. However, the initial tooling costs are high, and it’s primarily limited to non-ferrous metals.

Lost Wax Casting

Similar to investment casting, uses a wax model to create a mold. It’s excellent for intricate designs and fine details. The downside is the labor-intensive process and higher cost, limiting its use to small parts or art pieces.

Centrifugal Casting

Metal is poured into a rotating mold, using centrifugal force to distribute the metal. Suitable for cylindrical parts like pipes. Advantages include good material density and a clean surface. However, it’s limited to symmetrical shapes and requires specialized equipment.

Permanent Mold Casting

Involves pouring metal into reusable metal molds. It offers better surface finish and dimensional accuracy than sand casting. The limitation is the high tooling cost and difficulty in casting metals with high melting temperatures, making it less versatile.

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

Request a Quote for Cast Parts

Casting Materials Available

Casting can be performed in a number of ways depending on the composition and intended use of the final product. Some common materials available for Casting include the following.

Each of these materials has its own advantages, limitations, and cost implications. The choice of material and manufacturing technique usually depends on factors like the complexity of the design, required precision, material properties, and production volume.

Canyon Components strives to meet all customer service requests. Feel free to contact Canyon Components engineering and let our knowledgeable staff help you design the perfect part for your needs.

Metals

Metals are a class of materials distinguished by their conductive, malleable, and ductile properties. They are fundamental in various applications due to their ability to conduct electricity and heat, resist corrosion, and form alloys with other metals.

Aluminum

Aluminum, a lightweight, silver-white metal, is known for its remarkable corrosion resistance and high strength-to-weight ratio. It's easily machinable, conducts heat and electricity well, and is widely used in aerospace, transportation, and packaging industries due to its versatility.

Stainless Steel

Stainless steel, an alloy of iron, chromium, and often nickel, is renowned for its corrosion resistance and lustrous appearance. Its durability, easy maintenance, and hygienic qualities make it a popular choice in kitchenware, medical equipment, and architectural structures.

Titanium

Titanium is a lightweight, strong metal with a silvery-white appearance, known for its exceptional corrosion resistance and high strength-to-density ratio. Widely used in aerospace, medical implants, and sporting equipment, it forms alloys with elements like aluminum and vanadium.

Brass

Brass is a versatile alloy primarily composed of copper and zinc, known for its golden-yellow hue. It exhibits excellent malleability, acoustic properties, and resistance to corrosion, making it a popular choice for musical instruments, decorative items, and various fittings.

Bronze

Bronze, a copper-tin alloy, often contains small amounts of other elements like aluminum or nickel. It's known for its hardness, durability, and distinctive reddish-brown color. Widely used in sculpture, coins, and industrial applications, bronze resists corrosion and metal fatigue.

Copper

Copper is a reddish-brown, highly ductile and conductive metal, renowned for its thermal and electrical conductivity. It's naturally antimicrobial and corrosion-resistant, extensively used in electrical wiring, plumbing, coinage, and as a component in various metal alloys.

Nickel Alloy

Nickel alloy, a blend of nickel and other elements, is known for its exceptional corrosion resistance, heat resistance, and strength. It excels in harsh environments, making it ideal for aerospace, chemical processing, and power generation applications. Its silvery-white appearance adds to its appeal.

Plastics

Plastics are a broad class of synthetic or semi-synthetic materials known for their versatility and moldability. They are crucial in numerous applications due to their ability to be shaped, lightweight nature, and resistance to chemicals and moisture.

PMMA (Polymethyl Methacrylate)

Polymethyl Methacrylate (PMMA) Plastic, commonly known as acrylic or Plexiglas, is a transparent thermoplastic with glass-like clarity and excellent light transmission. It's durable, shatter-resistant, and used in applications like lenses, aquariums, signage, and various architectural features due to its weather-resistant properties.

ABS (Acrylonitrile Butadiene Styrene)

ABS plastic, a thermoplastic polymer blend of acrylonitrile, butadiene, and styrene, is renowned for its toughness, impact resistance, and rigidity. It's easily machinable and ideal for automotive parts, consumer goods, and 3D printing due to its strength and versatility.

PVC (Polyvinyl Chloride)

Polyvinyl Chloride (PVC) plastic, a widely utilized thermoplastic, is celebrated for its durability, chemical resistance, and versatility. It's commonly used in construction for pipes and fittings, medical devices, and window frames, and can be made more flexible with the addition of plasticizers.

Back to Manufacturing Hub

Get A Quote Now!

Groove Design References

Learn More

Coatings, Packaging, & Other Services

Learn More

Custom Parts & Custom O-rings

Learn More