Thermoforming

Thermoforming is a versatile manufacturing process used to create a wide range of plastic products by heating and shaping thermoplastic sheets or films. It's known for its efficiency and cost-effectiveness in producing items with varying complexity. In this web page, we will explore the different types of thermoforming, their advantages and disadvantages, and the diverse industrial applications. Additionally, we'll provide a list of materials commonly used in thermoforming manufacturing. Custom Thermoformed parts available now!

Check with one of Canyon’s helpful product engineers for an expert material and manufacturing recommendation.

Common terminology includes: Vacuum forming, pressure forming, drape forming, twin-sheet thermoforming, plug and play thermoforming, match metal thermoforming, billow thermoforming, rotational thermoforming, mechanical thermoforming, blister forming.

Advantages

- Cost-Effective: Suitable for both small and large-scale production runs.

- Complex Shapes: Allows for the production of intricate and complex parts.

- Material Efficiency: Minimizes waste, as excess material can often be recycled.

- Fast Prototyping: Rapid tooling and setup enable quick design iterations.

- Design Flexibility: Easily incorporates textures, logos, and undercuts.

Disadvantages

- Limited Material Compatibility: Not all materials are suitable for thermoforming.

- Cycle Times: Longer cycle times compared to some other manufacturing methods.

- Surface Finish: Achieving a smooth surface may necessitate additional processing steps.

Common Applications of Thermoforming

- Packaging: Manufacturing food trays, blister packaging, and clamshell containers.

- Automotive: Producing interior components, dashboards, and vehicle exteriors.

- Medical: Creating equipment enclosures, instrument housings, and trays.

- Consumer Goods: Fabricating display stands, cosmetic packaging, and toys.

- Aerospace: Manufacturing interior components, cockpit panels, and aircraft interiors.

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

Types of Thermoforming

Thermoforming can be performed in a number of ways depending on the composition and intended use of the final product. Some variations available for Thermoforming include the following.

Canyon Components strives to meet all customer service requests. Feel free to contact Canyon Components engineering and let our knowledgeable staff help you design the perfect part for your needs.

Vacuum Forming

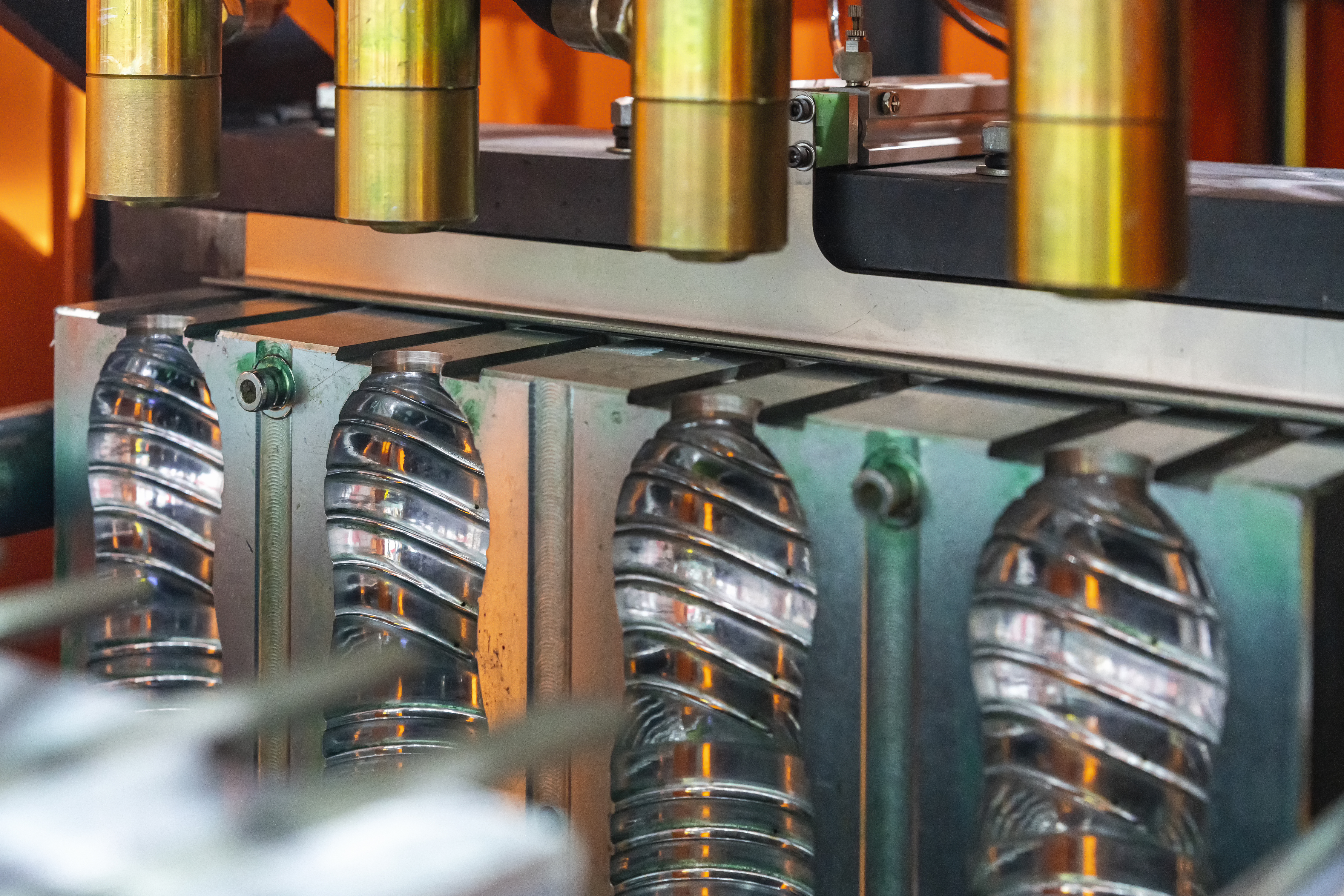

This method involves heating a plastic sheet until pliable, then using a vacuum to draw it into a mold. It's cost-effective for low to medium volume production and allows for detailed designs. However, it can result in uneven material distribution and is less suitable for complex geometries or deep draws.

Pressure Forming

Similar to vacuum forming, but with additional pressure applied to the opposite side of the sheet. This allows for greater detail and texture in the formed part. The advantage is higher quality and definition compared to vacuum forming, but it comes with higher tooling costs and longer cycle times.

Drape Forming

Involves draping a heated sheet over a mold. It's ideal for simple, large, or gently curved parts. The process is relatively simple and cost-effective. However, it’s limited in the complexity of shapes it can produce and may have less precision in wall thickness.

Twin-Sheet Thermoforming

Two plastic sheets are heated and formed separately, then fused together. This method creates strong, hollow parts and allows for different materials or colors for each sheet. The disadvantage is the complexity of the process and higher tooling costs.

Plug and Play Thermoforming

Uses a plug to pre-stretch the material before it’s vacuumed onto the mold, allowing for more uniform material distribution. This is beneficial for deeper or more intricate parts. The downside is the additional complexity and cost of the plug system.

Mechanical Thermoforming

Involves using mechanical forces, like a punch, to force the heated sheet into the mold. This is effective for creating precise shapes with sharp details. The advantage is the high level of detail and consistency, but it requires more sophisticated tooling and machinery.

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

Request a Quote for Thermoformed Parts

Thermoforming Materials Available

Thermoforming can be performed in a number of ways depending on the composition and intended use of the final product. Some common materials available for Thermoforming include the following.

Each of these materials has its own advantages, limitations, and cost implications. The choice of material and manufacturing technique usually depends on factors like the complexity of the design, required precision, material properties, and production volume.

Canyon Components strives to meet all customer service requests. Feel free to contact Canyon Components engineering and let our knowledgeable staff help you design the perfect part for your needs.

Plastics

Plastics are a broad class of synthetic or semi-synthetic materials known for their versatility and moldability. They are crucial in numerous applications due to their ability to be shaped, lightweight nature, and resistance to chemicals and moisture.

Specialty Compliances

Canyon have materials available for O-rings, gaskets, & custom parts with compliances ranging from USP Class VI <87> & <88> for medical applications, to FDA CFR 21.177.2600 grades A through F for different food types, to the various drinking water specifications like KTW and NSF. Whether it's metal, rubber, or plastic, Canyon can meet your needs!

PP (Polypropylene)

Polypropylene (PP) plastic, known for its exceptional chemical resistance and durability, is a lightweight thermoplastic. It's resilient against fatigue, has a high melting point, and is ideal for packaging, automotive parts, and textiles, thanks to its versatility and recyclability.

PS (Polystyrene)

Polystyrene (PS) plastic, a versatile and cost-effective thermoplastic, is known for its rigidity, clarity, and insulating properties. Widely used in packaging, disposable tableware, and insulation, PS is available in both solid and foam forms, catering to a broad range of applications.

PET (Polyethylene Terephthalate)

Polyethylene Terephthalate (PET) is a durable, lightweight thermoplastic, renowned for its clarity, strength, and recyclability. Widely used in beverage bottles, food packaging, and textiles, PET is also food-safe, resistant to water and many chemical solvents, and easily formed into various shapes.

Polyethylene (PE)

Polyethylene (PE) plastic, renowned for its versatility, is a widely used thermoplastic. It's lightweight, impact-resistant, and has excellent chemical resistance. Commonly used in packaging, containers, and pipes, PE is available in varying densities for different applications, including high and low-density forms.

PVC (Polyvinyl Chloride)

Polyvinyl Chloride (PVC) plastic, a widely utilized thermoplastic, is celebrated for its durability, chemical resistance, and versatility. It's commonly used in construction for pipes and fittings, medical devices, and window frames, and can be made more flexible with the addition of plasticizers.

PC (Polycarbonate)

Polycarbonate (PC) Plastic is a tough, transparent thermoplastic with exceptional impact resistance, heat tolerance, and optical clarity. Its versatility makes it ideal for bulletproof glass, eyewear lenses, medical devices, and protective gear, offering a unique balance of strength and lightweight properties.

PMMA (Polymethyl Methacrylate)

Polymethyl Methacrylate (PMMA) Plastic, commonly known as acrylic or Plexiglas, is a transparent thermoplastic with glass-like clarity and excellent light transmission. It's durable, shatter-resistant, and used in applications like lenses, aquariums, signage, and various architectural features due to its weather-resistant properties.

ABS (Acrylonitrile Butadiene Styrene)

ABS plastic, a thermoplastic polymer blend of acrylonitrile, butadiene, and styrene, is renowned for its toughness, impact resistance, and rigidity. It's easily machinable and ideal for automotive parts, consumer goods, and 3D printing due to its strength and versatility.

PC/ASA (Polycarbonate ASA Blend)

PC/ASA plastic, a blend of polycarbonate and acrylonitrile styrene acrylate, offers superior UV resistance, high heat stability, and excellent mechanical properties. Ideal for outdoor applications, it combines durability with aesthetic appeal and is widely used in automotive and electronics industries.

PC/ABS (Polycarbonate ABS Blend)

PC/ABS (Polycarbonate/Acrylonitrile Butadiene Styrene) Plastic is a robust blend combining the heat resistance and mechanical strength of polycarbonate with the flexibility and high-quality finish of ABS. Ideal for automotive, electronics, and consumer goods, it offers excellent impact resistance and durability.

Back to Manufacturing Hub

Get A Quote Now!

Groove Design References

Learn More

Coatings, Packaging, & Other Services

Learn More

Custom Parts & Custom O-rings

Learn More