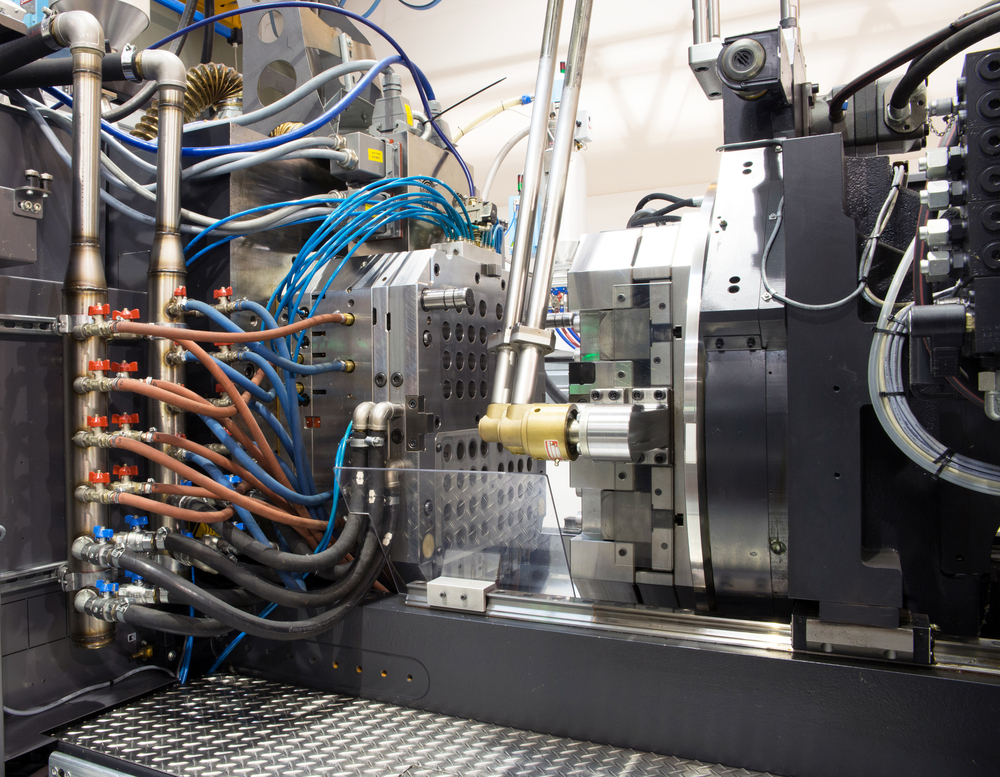

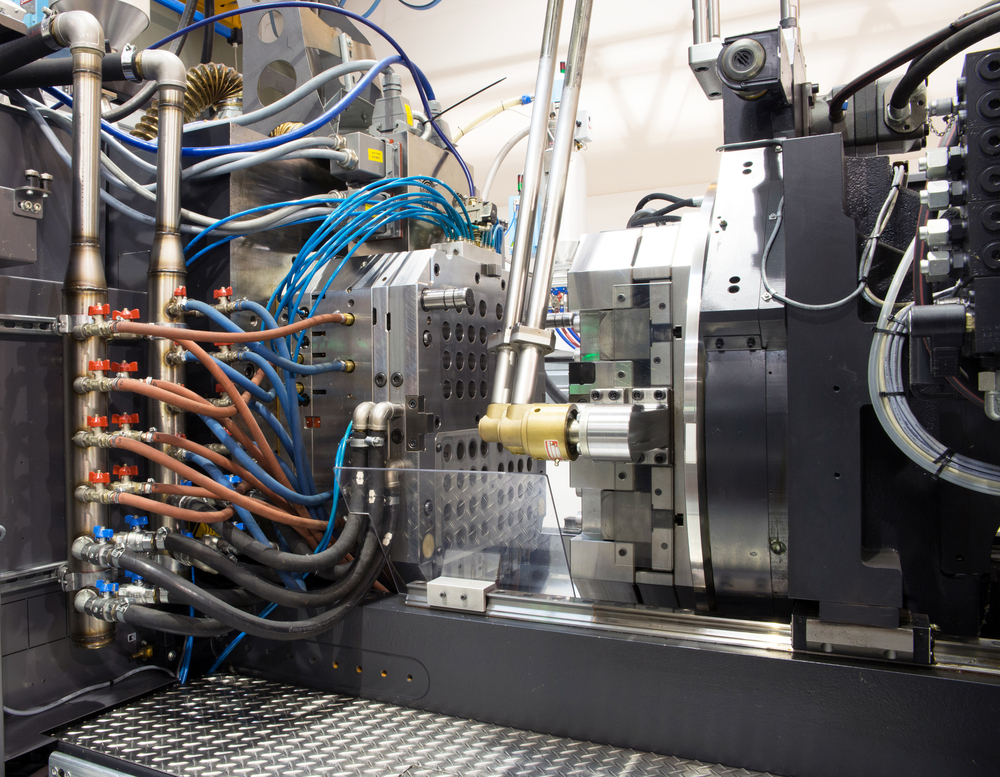

Injection Molding

Injection molding is a widely used manufacturing process that involves injecting molten material into a mold cavity to create a wide range of products and components. In this web page, we will explore the different types of injection molding, their advantages and disadvantages, and the industrial applications where this manufacturing method excels. Additionally, we'll provide a list of materials commonly used in injection molding.

Custom Injection Molded parts available now!

Check with one of Canyon’s helpful product engineers for an expert material and manufacturing recommendation.

Common names include: ABS plastic (Acrylonitrile Butadiene Styrene) Trade Names: Cycolac®, Lustran®, Royalite®, TECARAN™, Absylux®, Polystone®.

Advantages

- High Precision: Injection molding offers exceptional dimensional accuracy and repeatability, ensuring consistent part quality.

- Efficiency: It allows for high-volume production, reducing per-unit manufacturing costs.

- Versatility: A wide range of materials, including plastics, rubber, and metal powders, can be used in injection molding.

- Complex Geometry: Intricate and complex part designs can be easily achieved through injection molding.

- Reduced Material Waste: Minimal material waste as excess can be recycled.

Disadvantages

- High Initial Tooling Cost: Creating molds can be expensive, making it less suitable for low-volume production.

- Cycle Time: The process can have longer cycle times compared to other manufacturing methods.

- Material Limitations: Some materials may not be suitable for injection molding due to their properties.

- Design Constraints: Designing for injection molding requires consideration of moldability.

Common Applications of Injection Molding

- Automotive: Used for interior and exterior components, including dashboards, bumpers, and trim.

- Consumer Goods: Common in the production of toys, packaging, and household items.

- Medical: Manufacturing medical devices, syringes, and surgical instruments.

- Electronics: Producing electronic enclosures, connectors, and casings.

- Aerospace: Creating lightweight, precision components for aircraft and spacecraft.

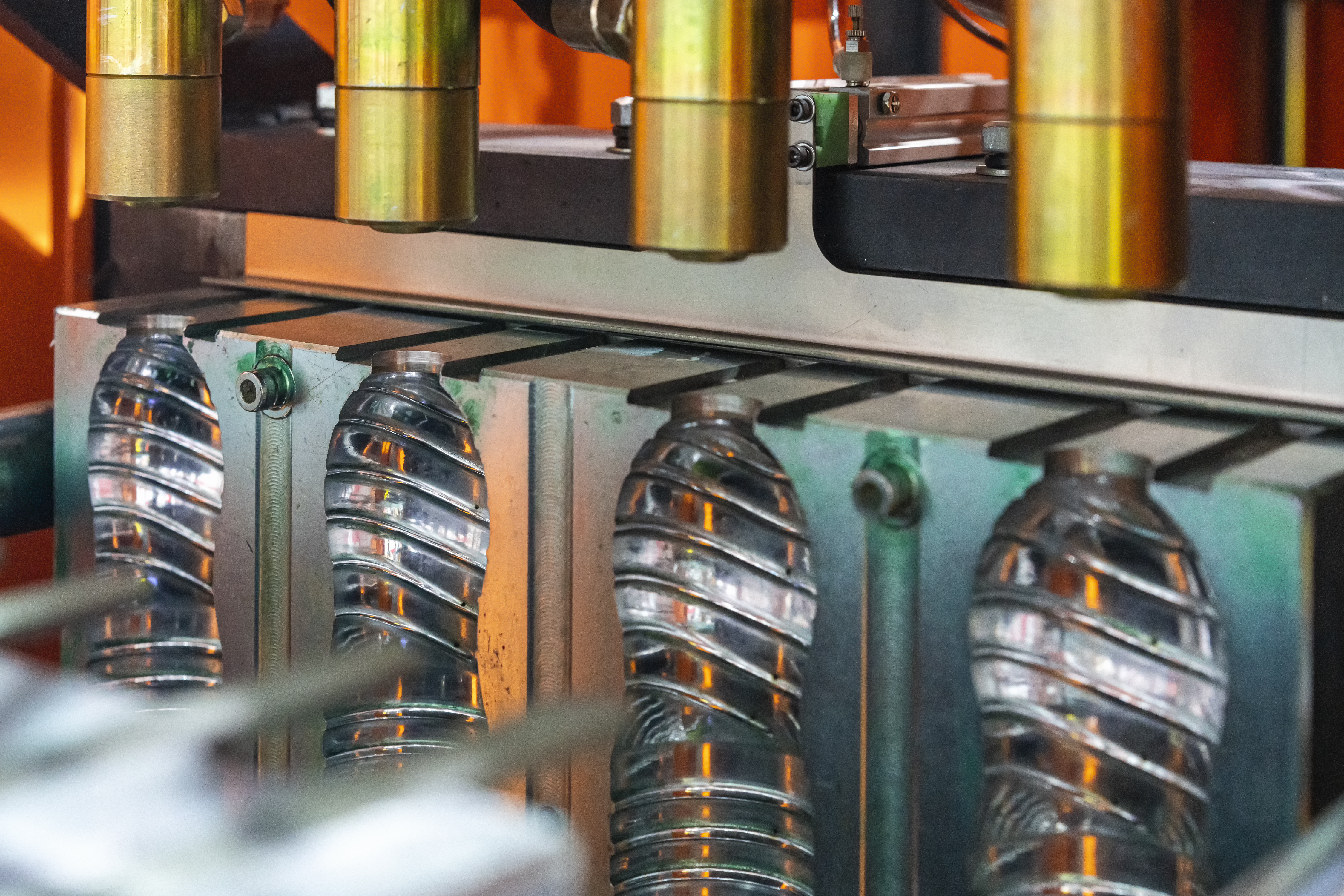

- Packaging: Making caps, closures, and containers for the food and beverage industry.

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

Types of Injection Molding

Injection Molding can be performed in a number of ways depending on the composition and intended use of the final product. Some variations available for Injection Molding include the following.

Canyon Components strives to meet all customer service requests. Feel free to contact Canyon Components engineering and let our knowledgeable staff help you design the perfect part for your needs.

Plastic Injection Molding

This process involves melting plastic pellets and injecting them into a mold cavity. It's ideal for high-volume production of plastic parts. Advantages include high efficiency, repeatability, and the ability to produce complex parts. Disadvantages are the initial cost of tooling and machinery, and limitations in designing parts due to molding constraints.

Thermoplastic Injection Molding

Involves injecting molten thermoplastic into molds. It's widely used due to the material's recyclability and versatility in industries like automotive and consumer goods. The main advantage is the ability to remelt and reshape. However, thermoplastics may not be suitable for high-temperature applications, and the process requires precise temperature control.

Thermoset Injection Molding

Uses thermosetting polymers that solidify permanently when heated. Common in applications requiring durable, heat-resistant parts like electrical insulators. The advantage is the superior material properties after curing. The disadvantage is that once set, these materials cannot be remelted or remolded, limiting recycling options

Overmolding

This involves molding a layer of material over a previously molded part. It’s used for adding soft touch surfaces or combining different materials. The advantage is the ability to create multi-material parts with varied textures. A disadvantage is the need for multiple molds and potentially longer cycle times.

Insert Molding

Involves molding plastic around pre-placed inserts, often made of metal. This is common in manufacturing electronic components. The advantage is the strong bond formed between the metal and plastic. However, the process can be complex and requires precise insert placement.

Micro-Injection Molding

Designed for producing extremely small, precise parts, often used in medical devices. The advantage is the high precision and ability to produce minute components. The main disadvantage is the high cost of precision tooling and the challenges in consistently producing such small parts.

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

Request a Quote for Injection Molded Parts

Injection Molding Materials Available

Injection Molding can be performed in a number of ways depending on the composition and intended use of the final product. Some common materials available for Injection Molding include the following.

Each of these materials has its own advantages, limitations, and cost implications. The choice of material and manufacturing technique usually depends on factors like the complexity of the design, required precision, material properties, and production volume.

Canyon Components strives to meet all customer service requests. Feel free to contact Canyon Components engineering and let our knowledgeable staff help you design the perfect part for your needs.

Elastomers

Elastomers (also referred to as rubber) are a class of materials known for their unique ability to stretch, deform, and return to their original shape, making them essential in a wide range of applications.

Perfluoroelastomers (FFKM, Kalrez, CanRez)

Extreme temperatures & chemicals require extreme solutions! CanRez™ FFKM materials offer extreme reliability where you need it most! Thousands of sizes in stock now!

Silicone (VMQ, PVMQ)

Silicone seals, O-rings, gaskets, & custom molded parts are excellent for extreme temperatures in static applications. Canyon Components carries a range of silicone materials, and we are happy to custom tailor a seal to meet your application requirements!

FKM (Viton®, Fluorocarbon)

FKM compounds, O-rings, gaskets, & custom molded parts exhibit excellent mechanical attributes as well as excellent resistance to high temperatures, mineral oil, ozone, fuels, hydraulic fluids, and many other solvents and chemicals.

EPDM (Ethylene Propylene)

EPDM materials, O-rings, gaskets, & custom molded parts can operate over a wide temperature range, and are compatible with glycol fluids that cause problems for most typical elastomeric seals.

Plastics

Plastics are a broad class of synthetic or semi-synthetic materials known for their versatility and moldability. They are crucial in numerous applications due to their ability to be shaped, lightweight nature, and resistance to chemicals and moisture.

PEEK (Polyetheretherketone)

PEEK plastic, or polyether ether ketone, is a high-performance thermoplastic known for its exceptional heat resistance, chemical stability, and mechanical strength. It's widely used in aerospace, medical implants, and automotive industries for its durability and ability to withstand harsh environments.

Nylon (Polyamide, PA)

Nylon, a synthetic thermoplastic polymer, is renowned for its high strength, elasticity, and abrasion resistance. It's versatile, easily dyeable, and used in a wide range of products from textiles and ropes to gears and automotive parts.

PC (Polycarbonate)

Polycarbonate (PC) Plastic is a tough, transparent thermoplastic with exceptional impact resistance, heat tolerance, and optical clarity. Its versatility makes it ideal for bulletproof glass, eyewear lenses, medical devices, and protective gear, offering a unique balance of strength and lightweight properties.

Specialty Compliances

Canyon have materials available for O-rings, gaskets, & custom parts with compliances ranging from USP Class VI <87> & <88> for medical applications, to FDA CFR 21.177.2600 grades A through F for different food types, to the various drinking water specifications like KTW and NSF. Whether it's metal, rubber, or plastic, Canyon can meet your needs!

POM (Polyoxymethylene, Acetal)

Polyoxymethylene (POM) Plastic, also known as Acetal or Delrin, is a high-strength, low-friction thermoplastic. It's characterized by its dimensional stability, excellent wear resistance, and low moisture absorption, making it ideal for precision parts in automotive and consumer electronics.

PPSU (Polyphenylsulfone)

Polyphenylsulfone (PPSU) Plastic is a high-performance thermoplastic known for its exceptional heat resistance, toughness, and stability under thermal stress. It's widely used in medical instruments, aerospace, and plumbing components due to its excellent chemical resistance and ability to withstand repeated sterilizations.

PVC (Polyvinyl Chloride)

Polyvinyl Chloride (PVC) plastic, a widely utilized thermoplastic, is celebrated for its durability, chemical resistance, and versatility. It's commonly used in construction for pipes and fittings, medical devices, and window frames, and can be made more flexible with the addition of plasticizers.

Back to Manufacturing Hub

Get A Quote Now!

Groove Design References

Learn More

Coatings, Packaging, & Other Services

Learn More

Custom Parts & Custom O-rings

Learn More