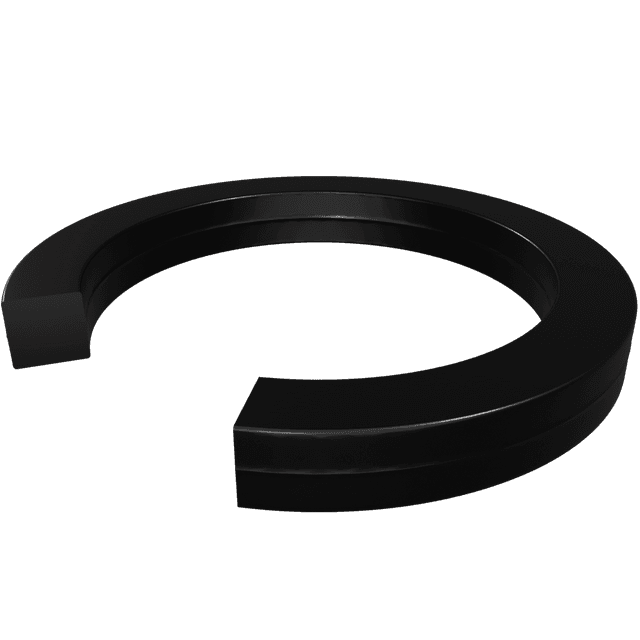

Square Rings - Details, Selection, Installation, & Maintenance

Square rings, also known as square-section seals, are a versatile and reliable sealing solution used in a variety of applications. Unlike traditional O-rings with a round cross-section, square rings have a square-shaped profile, providing distinct advantages in certain applications. This guide covers the features, common applications, types, manufacturing options, and essential guidelines for selection, installation, and maintenance of square rings.

CanRez® FFKM and Kalrez® square rings, gasket rapid manufacturing, & custom molded parts are available now!

Check with one of Canyon’s helpful product engineers for an expert material and manufacturing recommendation.

Features of Square Rings

Square rings offer several unique features that make them suitable for specific sealing needs:

- Enhanced Stability: The flat sides of square rings provide better resistance to rolling and twisting, which can be a common issue with round O-rings in dynamic applications.

- Improved Sealing Surface: With a larger surface area in contact with the sealing groove, square rings offer a more robust seal, particularly in static applications.

- Low Compression Set: Square rings often have a lower compression set compared to O-rings, meaning they maintain their shape and sealing ability over time.

- Versatility: Square rings can be used in various static and dynamic applications, making them suitable for a wide range of industries.

- Cost-Effective: Square rings are relatively inexpensive to manufacture and can often be a more affordable solution compared to custom-designed seals.

Common Applications of Square Rings

Square rings are used in a wide array of industries and applications due to their unique design and performance benefits:

- Hydraulics and Pneumatics: Square rings are often used in hydraulic and pneumatic systems where a robust and reliable static seal is required.

- Automotive: Square rings are used in automotive components such as fuel systems, transmissions, and braking systems where stability and sealing integrity are critical.

- Aerospace: In aerospace applications, square rings provide reliable sealing in systems subjected to extreme pressures and temperatures.

- Industrial Machinery: Square rings are found in pumps, compressors, and valves where they prevent leaks and ensure the efficient operation of machinery.

- Medical Devices: Square rings are used in medical equipment where precision sealing and resistance to sterilization processes are essential.

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

Get a Quote Now!

Types of Square Rings

CanRez® FFKM Perfluoroelastomer

Extreme temperatures & chemicals require extreme solutions! CanRez® FFKM Square Ring materials offer extreme reliability where you need it most! Thousands of sizes in stock now!

CanGuard™ RFI & EMI Shielding Materials

CanGuard™ materials have been developed to offer superior sealing solutions with enhanced electromagnetic interference (EMI) shielding and radio frequency interference (RFI) shielding in an Square Ring format.

Kalrez® FFKM Perfluoroelastomer

Canyon Components offers Kalrez® Perfluoroelastomer (FFKM) Square Rings, O-rings, gaskets, & custom molded parts at competitive prices and with great lead-times.

Parker® Square Rings, Parofluor parts, parker FKM Viton

Canyon Components offers Parker Hannifin® Square Rings, O-rings, Gaskets, Perfluoroelastomer (FFKM) parts, & custom molded parts at competitive prices and with great lead-times.

FKM (Viton®, Fluorocarbon)

FKM compounds, Square Rings, O-rings, gaskets, & custom molded parts exhibit excellent mechanical attributes as well as excellent resistance to high temperatures, mineral oil, ozone, fuels, hydraulic fluids, and many other solvents and chemicals.

Aflas® (TFE/P)

TFE/P (Aflas) compounds, Square Rings, O-rings, gaskets, & custom molded parts gives high resistance to steam, hot water, atmospheric wear, and many chemicals. TFE/P compounds provide superior performance in water, steam and virtually all caustic chemicals.

Fluorosilicone (FVMQ)

The mechanical and physical properties of Fluorosilicone Square Rings, O-rings, gaskets, & custom molded parts are very similar to silicone. Fluorosilicone Square Rings, O-rings, gaskets, & custom molded parts offer improved flexibility and strength, better resistance to fuels and mineral oil, but reduced hot air resistance.

Silicone (VMQ, PVMQ)

Silicone seals, Square Rings, O-rings, gaskets, & custom molded parts are excellent for extreme temperatures in static applications. Canyon Components carries a range of silicone materials, and we are happy to custom tailor a seal to meet your application requirements!

EPDM (Ethylene Propylene)

EPDM materials, Square Rings, O-rings, gaskets, & custom molded parts can operate over a wide temperature range, and are compatible with glycol fluids that cause problems for most typical elastomeric seals.

NBR (Nitrile, Buna-N)

Nitrile Square Rings, O-rings, gaskets, & custom molded parts are very oil-resistant, have strong mechanical properties, are resistant to wear, and are relatively inexpensive. These properties make Nitrile the most commonly used general purpose O-ring, gasket, & custom molded part material.

HNBR (Hydrogenated Nitrile)

Hydrogenated Nitrile Square Rings, O-rings, gaskets, & custom molded parts offer higher strength and reduced degradation at high temperatures compared to conventional Nitrile materials. These properties make HNBR materials popular in the oil and gas industry, as well as many applications in the chemical industry.

XNBR (Carboxylated Nitrile)

XNBR Square Rings, O-rings, gaskets, & custom molded parts are similar to Nitrile, but the backbone has been chemically modified with a Carboxylic Acid group. The resulting elastomer is a Nitrile rubber with outstanding abrasion and chemical resistance, superior to that of traditional Nitrile.

Neoprene (CR)

Chloroprene was the first synthetic rubber, and was developed commercially under the name Neoprene®. Chloroprene rubbers, Square Rings, O-rings, gaskets, & custom molded parts contain Chlorine in the polymer to reduce the reactivity to many oxidizing agents, as well as to oil and flame.

Polyurethane (PU, AU)

Polyurethane Square Rings, O-rings, gaskets, & custom molded parts generally have two or three times greater tensile strength and wear resistance than Nitrile and comparable polymers. Polyurethane also provides excellent permeation resistance when compared to most rubbers.

PTFE O-Rings

The harshest environments require specialized solutions. Often times, a Canyon Components PTFE Square Rings are used in harsh chemical environments. Polytetrafluoroethylene, commonly known as PTFE or Teflon®, is a high-performance fluoropolymer known for its exceptional chemical resistance, low friction, and non-stick properties.

Product Types

Custom Parts

Here at Canyon Components, we make sure to offer our customers any manufacturing technique they desire. Whether your Square Rings, O-rings, gaskets, & custom molded parts be rubber, plastic, or metal, rest assured that Canyon Components can make it!

Gaskets & Custom Cutting

Whether your custom cut parts be Square Rings, rubber, plastic, sponge, composite, or metal, rest assured that Canyon Components can make it! Canyon Components strives to meet all customer service requests. If you need something that isn't listed, feel free to contact a Canyon Components product and application consultant.

Infinite "Giant" Diameter Square Rings

By either Continuous Molding Square Rings, or Splice & Vulcanizing Square Rings, Canyon can provide mold-less, infinitely large Square Rings at competitive prices!

Specialty Compliances

Canyon have materials available for Square Rings, gaskets, & custom parts with compliances ranging from USP Class VI <87> & <88> for medical applications, to FDA CFR 21.177.2600 grades A through F for different food types, to the various drinking water specifications like KTW and NSF. Whether it's metal, rubber, or plastic, Canyon can meet your needs!

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

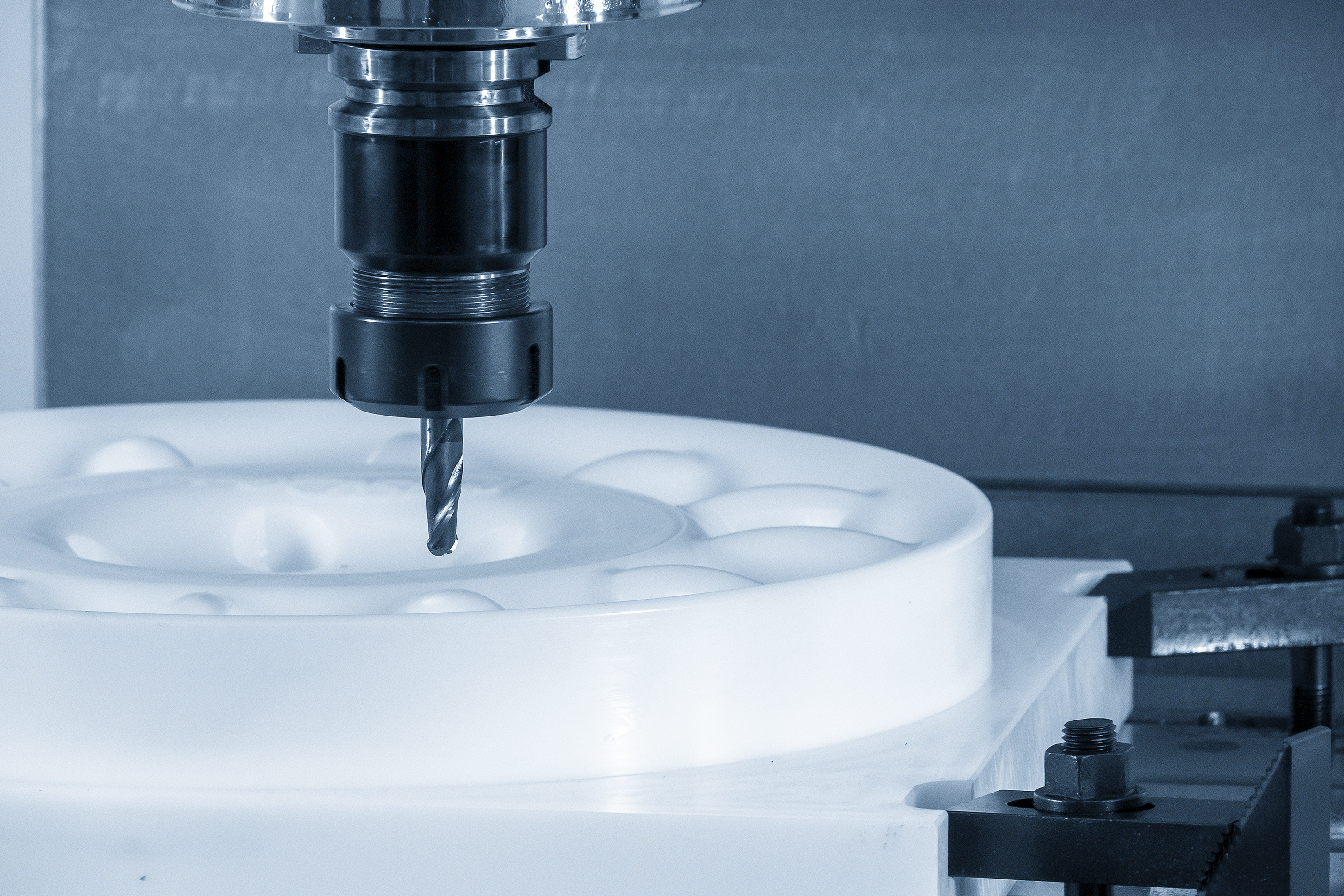

Manufacturing Options for Square Rings

Square rings can be manufactured using various methods, each offering different advantages depending on the application:

Canyon Components strives to meet all customer service requests. Feel free to contact Canyon Components engineering and let our knowledgeable staff help you design the perfect part for your needs.

Injection Molding

Injection molding is ideal for high-volume production, ensuring consistent quality and precision in the final product.

Compression Molding

This method uses heat and pressure to shape square rings, making it a cost-effective solution for smaller production runs.

Splice & Vulcanized

For custom-sized Square Rings, extrusion followed by cutting to length and splice & vulcanization is a common method, allowing for a high degree of customization.

Die Cutting

Die-cutting from sheets of material is an efficient and cost-effective option for producing flat square rings or gaskets.

Extrusion & Cutting

For custom-sized Square Rings, extrusion followed by cutting to length is a common method, offering a high degree of customization.

Square Ring Selection, Installation, and Maintenance

Square rings offer a robust and reliable sealing solution for various industries and applications. By understanding the features, types, and manufacturing options available, along with proper selection, installation, and maintenance practices, you can ensure optimal performance and longevity of square rings in your specific application. Whether you're working in automotive, aerospace, medical, or industrial sectors, square rings provide the stability and durability required to keep systems running smoothly.

Canyon Components strives to meet all customer service requests. Feel free to contact Canyon Components engineering and let our knowledgeable staff help you design the perfect part for your needs.

Selection of Square Rings

Choosing the right square ring for your application is essential for ensuring optimal performance. Consider the following factors during selection:

- Material Compatibility: Ensure the square ring material is compatible with the fluids or gases it will come into contact with. For example, nitrile is suitable for oil-based fluids, while Viton is better for high-temperature and chemical applications.

- Temperature Range: Select a square ring material that can withstand the operating temperature of your system.

- Pressure Rating: Choose a square ring that can handle the pressure levels in your application to prevent deformation or failure.

- Size and Fit: Proper sizing is critical for ensuring a tight seal. A square ring that is too large or too small can lead to leaks or premature wear.

- Application Type: Determine whether the square ring will be used in a static or dynamic application, as this will influence material and design choices.

Installation of Square Rings

Proper installation is key to ensuring the effectiveness of square rings. Follow these guidelines for a correct installation:

- Inspect the Square Ring: Before installation, inspect the square ring for any defects, such as nicks, cuts, or deformations.

- Use Lubrication: Apply a compatible lubricant to the square ring to reduce friction during installation and prevent damage to the seal.

- Avoid Overstretching: Do not overstretch the square ring during installation, as this can cause it to lose its shape and sealing effectiveness.

- Align Properly: Ensure the square ring is properly seated in the groove and that it is not twisted or pinched.

- Use Installation Tools: When necessary, use specialized installation tools to avoid damaging the square ring.

Maintenance of Square Rings

Regular maintenance can extend the lifespan of square rings and prevent system failures. Consider the following maintenance practices:

- Regular Inspections: Periodically inspect square rings for signs of wear, cracking, or deformation. Replace any square rings that show signs of damage.

- Monitor Operating Conditions: Ensure that the system’s operating conditions, such as pressure, temperature, and chemical exposure, remain within the square ring’s specified limits.

- Clean Regularly: Keep the square rings and surrounding components clean to prevent debris from causing wear or damage.

- Use the Right Lubricants: Maintain proper lubrication to reduce friction and wear on the square ring during operation.

- Replace as Needed: Even with proper maintenance, square rings will eventually wear out. Replace them according to the manufacturer’s recommended intervals or when signs of failure are evident.

Back to Products Hub

Get A Quote Now!