Fasteners - Standard & Custom

Fasteners are essential components used to mechanically join or secure objects together. They come in a wide range of shapes, sizes, and materials to suit various applications across different industries. Whether you're building machinery, assembling electronics, or constructing buildings, fasteners play a critical role in ensuring structural integrity and reliability. This guide covers the features of fasteners, the differences between standard and custom options, common applications, and the materials used in their construction.

Custom fasteners and rapid prototyping available now!

Check with one of Canyon’s helpful product engineers for an expert material and manufacturing recommendation.

Features of Fasteners

Fasteners are designed with several key features that make them indispensable in numerous applications:

- Mechanical Strength: Fasteners provide the necessary strength to hold components together, ensuring the stability and durability of assemblies.

- Versatility: Available in various designs, including screws, bolts, nuts, and rivets, fasteners can be used in a wide range of applications, from light-duty to heavy-duty tasks.

- Ease of Installation: Many fasteners are designed for easy installation and removal, allowing for quick assembly and disassembly of components.

- Corrosion Resistance: Fasteners are often coated or made from materials that resist corrosion, ensuring long-lasting performance in harsh environments.

- Precision: High-quality fasteners offer precise dimensions and threading, ensuring a secure and reliable fit in any application.

Common Applications of Fasteners

Fasteners are used across virtually every industry due to their versatility and reliability. Some common applications include:

- Construction: Fasteners are essential in building structures, including bridges, buildings, and infrastructure. Examples include anchor bolts, wood screws, and concrete fasteners.

- Automotive: Fasteners are used to assemble engines, transmissions, and other automotive components, ensuring the safety and performance of vehicles. Examples include lug nuts, hose clamps, and exhaust clamps.

- Aerospace: In aerospace, fasteners are critical for assembling aircraft and spacecraft, where precision and strength are paramount. Examples include high-strength bolts, rivets, and specialty aerospace fasteners.

- Electronics: Fasteners in electronics secure circuit boards, components, and enclosures, ensuring reliable performance in compact and delicate assemblies. Examples include small screws, standoffs, and clips.

- Manufacturing: Fasteners are widely used in manufacturing machinery, tools, and equipment, ensuring the efficient and reliable operation of industrial systems. Examples include socket head cap screws, threaded inserts, and retaining rings.

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

Get a Quote Now!

Metal Fastener Options

Steel Fasteners

Steel is a strong, durable alloy primarily made from iron and carbon. It's characterized by its high tensile strength and resistance to corrosion and wear. Steel often contains additional elements like chromium, nickel, and manganese to enhance its properties.

Carbon Steel Fasteners

Carbon steel, a robust alloy of iron and carbon, is distinguished by its impressive tensile strength, hardness, and ability to be magnetized. Predominantly used in construction and manufacturing, it features a silver-gray appearance and excels in durability and wear resistance.

Alloy Steel Fasteners

Alloy steel is a robust metal composed of iron mixed with various elements like chromium, nickel, molybdenum, and vanadium. This combination enhances properties such as strength, hardness, durability, and corrosion resistance, making it ideal for diverse industrial applications.

Stainless Steel Fasteners

Stainless steel, an alloy of iron, chromium, and often nickel, is renowned for its corrosion resistance and lustrous appearance. Its durability, easy maintenance, and hygienic qualities make it a popular choice in kitchenware, medical equipment, and architectural structures.

Aluminum Fasteners

Aluminum, a lightweight, silver-white metal, is known for its remarkable corrosion resistance and high strength-to-weight ratio. It's easily machinable, conducts heat and electricity well, and is widely used in aerospace, transportation, and packaging industries due to its versatility.

Brass Fasteners

Brass is a versatile alloy primarily composed of copper and zinc, known for its golden-yellow hue. It exhibits excellent malleability, acoustic properties, and resistance to corrosion, making it a popular choice for musical instruments, decorative items, and various fittings.

Bronze Fasteners

Bronze, a copper-tin alloy, often contains small amounts of other elements like aluminum or nickel. It's known for its hardness, durability, and distinctive reddish-brown color. Widely used in sculpture, coins, and industrial applications, bronze resists corrosion and metal fatigue.

Copper Fasteners

Copper is a reddish-brown, highly ductile and conductive metal, renowned for its thermal and electrical conductivity. It's naturally antimicrobial and corrosion-resistant, extensively used in electrical wiring, plumbing, coinage, and as a component in various metal alloys.

Iron Fasteners

Iron is a lustrous, ductile, malleable metal with a silvery-gray appearance. As a fundamental building block of modern industry, it is magnetic, has high melting and boiling points, and forms compounds with various elements, prominently influencing Earth's geology and human technology.

Magnesium Alloy Fasteners

Magnesium alloy, a lightweight and strong metal, is characterized by its low density, high strength-to-weight ratio, and excellent machinability. It's often used in aerospace, automotive industries, and electronics for its weight-saving benefits and ability to dissipate heat effectively.

Nickel Alloy Fasteners

Nickel alloy, a blend of nickel and other elements, is known for its exceptional corrosion resistance, heat resistance, and strength. It excels in harsh environments, making it ideal for aerospace, chemical processing, and power generation applications. Its silvery-white appearance adds to its appeal.

Titanium Fasteners

Titanium is a lightweight, strong metal with a silvery-white appearance, known for its exceptional corrosion resistance and high strength-to-density ratio. Widely used in aerospace, medical implants, and sporting equipment, it forms alloys with elements like aluminum and vanadium.

Tungsten Carbide Fasteners

Tungsten carbide, a composite of tungsten and carbon, is exceptionally hard and wear-resistant. It has a high melting point and great rigidity, making it ideal for cutting tools, abrasives, and armor-piercing rounds. Its density and strength are comparable to those of diamond.

Zinc Alloy Fasteners

Zinc alloy is a robust metal combination mainly composed of zinc, often blended with aluminum, copper, and magnesium. It's known for its high strength, good corrosion resistance, and ability to be cast into intricate shapes, commonly used in die-casting and automotive parts.

Plastic Fastener Options

Nylon Fasteners (Polyamide, PA)

Nylon, a synthetic thermoplastic polymer, is renowned for its high strength, elasticity, and abrasion resistance. It's versatile, easily dyeable, and used in a wide range of products from textiles and ropes to gears and automotive parts.

PEEK Fasteners (Polyetheretherketone)

PEEK plastic, or polyether ether ketone, is a high-performance thermoplastic known for its exceptional heat resistance, chemical stability, and mechanical strength. It's widely used in aerospace, medical implants, and automotive industries for its durability and ability to withstand harsh environments.

PP Fasteners (Polypropylene)

Polypropylene (PP) plastic, known for its exceptional chemical resistance and durability, is a lightweight thermoplastic. It's resilient against fatigue, has a high melting point, and is ideal for packaging, automotive parts, and textiles, thanks to its versatility and recyclability.

PTFE Fasteners (Polytetrafluoroethylene, Teflon)

Polytetrafluoroethylene (PTFE) Plastic, commonly known as Teflon, is a highly non-reactive and low-friction thermoplastic. Renowned for its outstanding chemical resistance, heat tolerance, and electrical insulation properties, it's extensively used in cookware coatings, electrical insulation, and various industrial applications.

PVC Fasteners (Polyvinyl Chloride)

Polyvinyl Chloride (PVC) plastic, a widely utilized thermoplastic, is celebrated for its durability, chemical resistance, and versatility. It's commonly used in construction for pipes and fittings, medical devices, and window frames, and can be made more flexible with the addition of plasticizers.

PPSU Fasteners (Polyphenylsulfone)

Polyphenylsulfone (PPSU) Plastic is a high-performance thermoplastic known for its exceptional heat resistance, toughness, and stability under thermal stress. It's widely used in medical instruments, aerospace, and plumbing components due to its excellent chemical resistance and ability to withstand repeated sterilizations.

Product Types

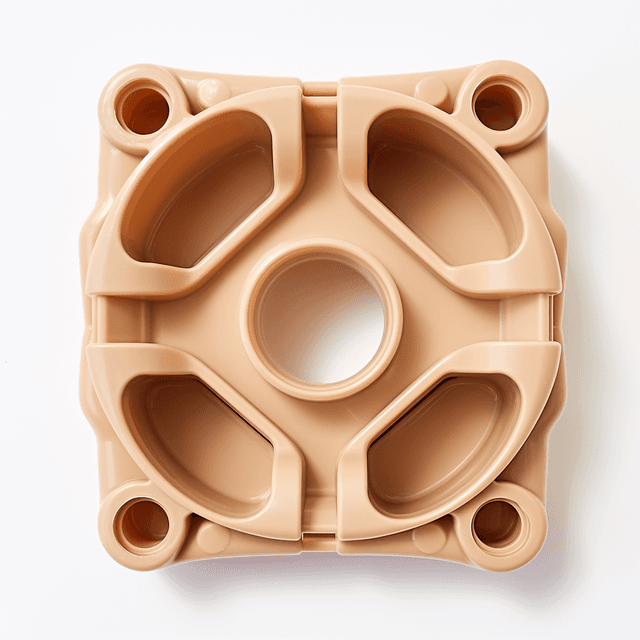

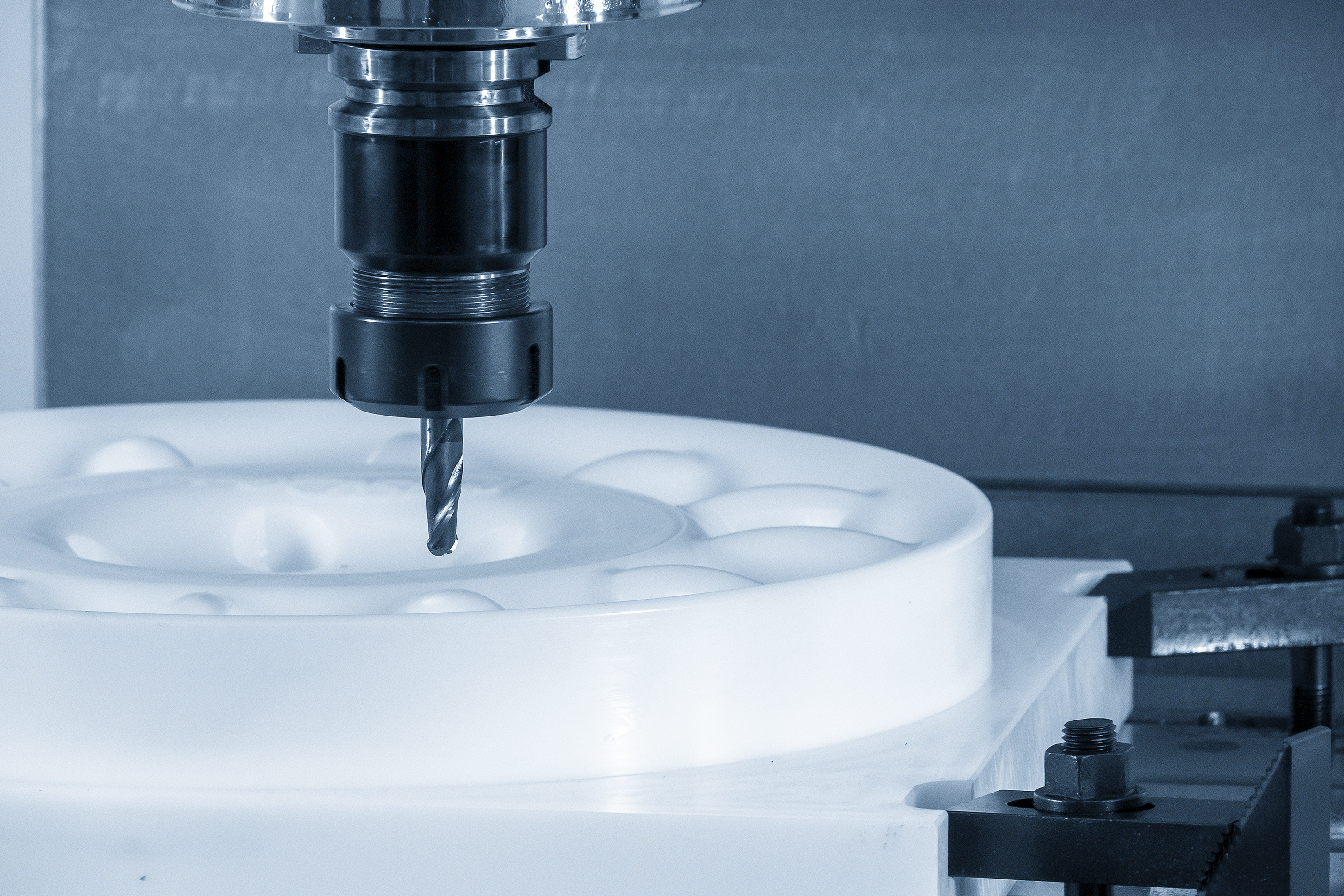

Custom Fasteners

Here at Canyon Components, we make sure to offer our customers any manufacturing technique they desire. Whether your fasteners, custom metal parts, gaskets, & custom molded parts be rubber, plastic, or metal, rest assured that Canyon Components can make it!

Specialty Compliances

Canyon have materials available for fasteners, O-rings, gaskets, & custom parts with compliances ranging from USP Class VI <87> & <88> for medical applications, to FDA CFR 21.177.2600 grades A through F for different food types, to the various drinking water specifications like KTW and NSF. Whether it's metal, rubber, or plastic, Canyon can meet your needs!

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

Standard and Custom Fasteners

Fasteners are a crucial component in countless applications, providing the mechanical strength and stability needed to securely join components together. Whether you need standard fasteners for everyday tasks or custom fasteners for specialized applications, understanding the different types, materials, and features available will help you select the right fasteners for your needs. With their versatility, durability, and ease of use, fasteners remain an essential element in construction, manufacturing, and beyond.

Fasteners are available in both standard and custom configurations to meet the specific needs of different projects:

Canyon Components strives to meet all customer service requests. Feel free to contact Canyon Components engineering and let our knowledgeable staff help you design the perfect part for your needs.

Standard Fasteners

These are pre-manufactured fasteners that conform to industry standards, such as ANSI, ISO, or DIN. Standard fasteners are readily available in various sizes, materials, and finishes, making them a convenient and cost-effective choice for many applications. Common examples include hex bolts, machine screws, and flat washers.

Custom Fasteners

When a project requires unique specifications, custom fasteners can be manufactured to meet specific design, material, or performance requirements. Custom fasteners are often used in specialized industries, such as aerospace, automotive, and medical devices, where standard fasteners may not meet the necessary criteria. Customization options can include unique threading, non-standard dimensions, or specialized materials.

Back to Products Hub

Get A Quote Now!