Bonded Metal-to-Rubber Parts

Bonded metal-to-rubber parts are essential components in various industries, where they provide a combination of the strength and durability of metal with the flexibility and resilience of rubber. These parts are manufactured using a process known as overmolding, which ensures a secure bond between the metal and rubber materials. This guide covers the features, common applications, and the pros and cons of bonded metal-to-rubber parts, with detailed information about the overmolding manufacturing process.

CanRez® FFKM and Kalrez® overmolded parts, grommets, O-rings, gasket rapid manufacturing, & custom molded parts are available now!

Check with one of Canyon’s helpful product engineers for an expert material and manufacturing recommendation.

Features of Bonded Metal-to-Rubber Parts

Bonded metal-to-rubber parts offer several unique features that make them ideal for demanding applications:

- Strong Bonding: The overmolding process ensures a strong, permanent bond between the metal and rubber materials, preventing delamination and ensuring long-lasting performance.

- Durability: These parts combine the structural strength of metal with the flexibility and shock absorption properties of rubber, making them highly durable and capable of withstanding harsh conditions.

- Versatile Design: Bonded metal-to-rubber parts can be designed to meet specific application requirements, with various shapes, sizes, and material combinations available.

- Vibration and Noise Damping: The rubber component effectively absorbs vibrations and reduces noise, protecting the metal part and the surrounding equipment from damage.

- Corrosion Resistance: The rubber layer provides a protective barrier against moisture and chemicals, preventing corrosion of the metal substrate and extending the life of the part.

Common Applications of Bonded Metal-to-Rubber Parts

Bonded metal-to-rubber parts are used in a wide range of industries and applications where reliable performance and durability are essential:

- Automotive: These parts are commonly used in automotive applications, such as engine mounts, suspension bushings, and vibration isolators, where they help reduce noise, vibration, and harshness (NVH).

- Industrial Machinery: In industrial machinery, bonded metal-to-rubber parts are used in mounts, seals, and gaskets to absorb vibrations, reduce noise, and protect against wear and corrosion.

- Aerospace: The aerospace industry uses these parts in landing gear components, engine mounts, and other critical systems where reliable performance under extreme conditions is required.

- Marine: Bonded metal-to-rubber parts are used in marine applications, such as propeller shaft seals and engine mounts, where they provide resistance to saltwater corrosion and absorb vibrations from engine operation.

- Construction Equipment: In construction machinery, these parts are used in various components to reduce vibration and noise, improve operator comfort, and extend the life of the equipment.

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

Get a Quote Now!

Overmolding Manufacturing Process

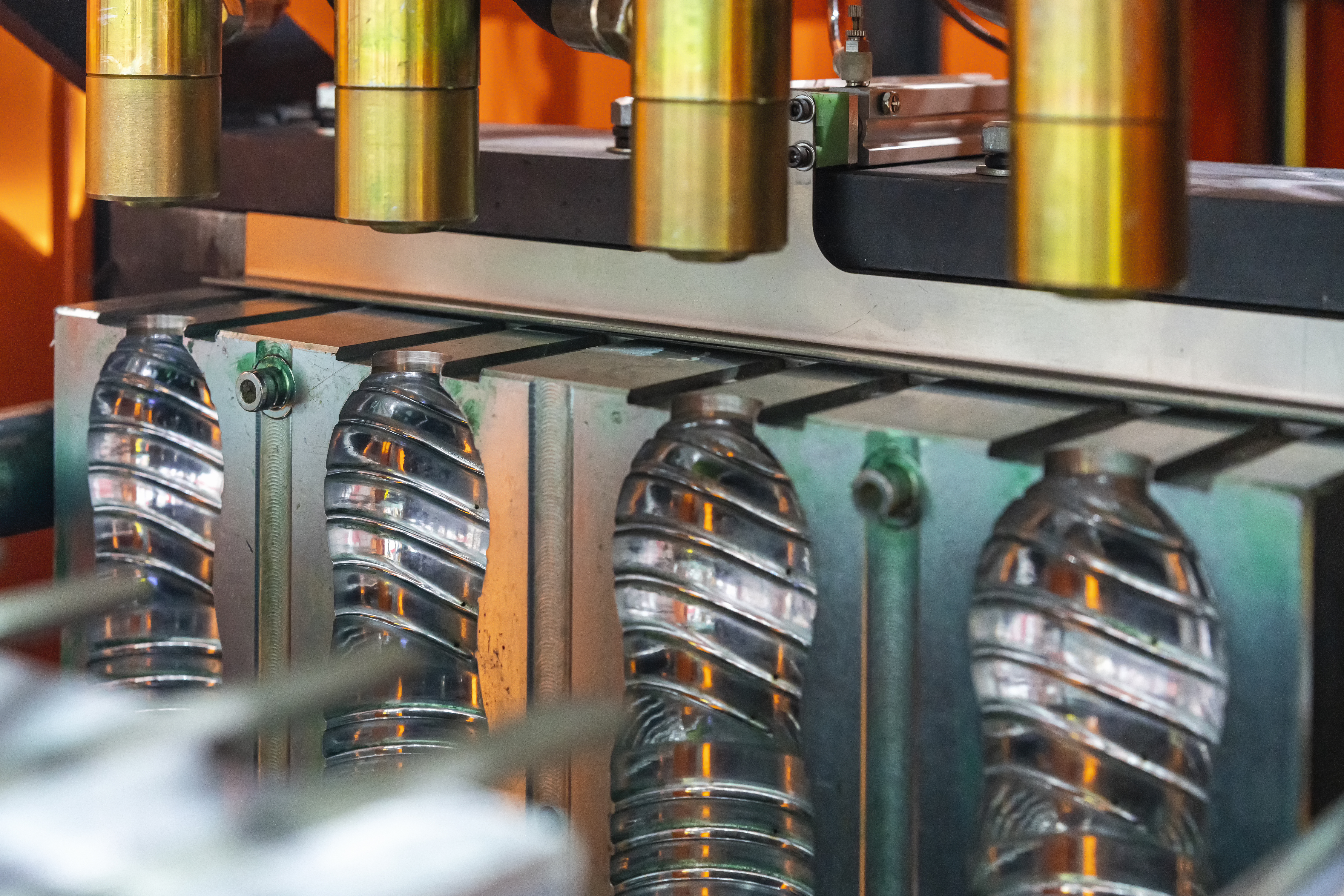

Overmolding is the manufacturing process used to create bonded metal-to-rubber parts. This process involves the following steps:

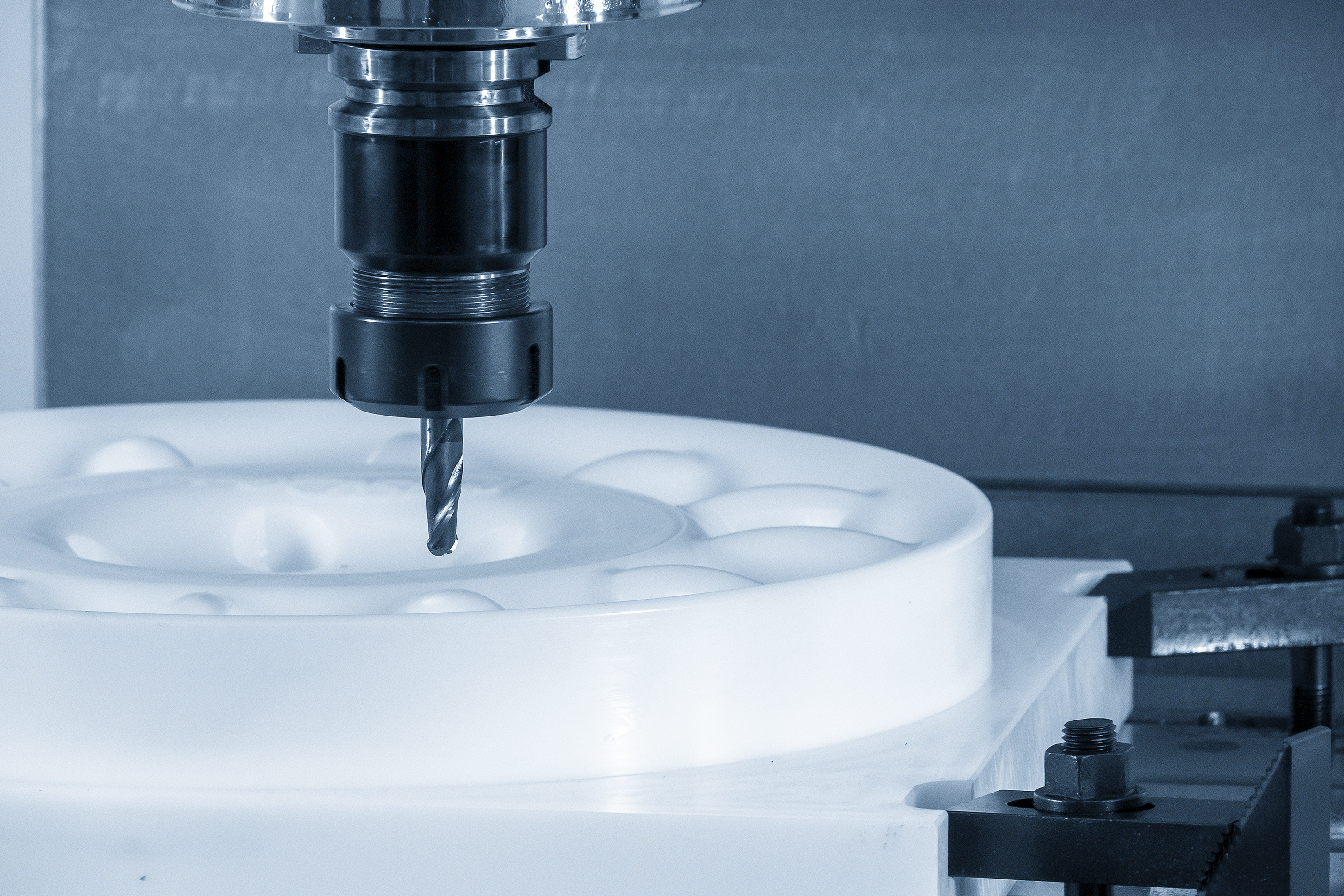

- Preparation of the Metal Substrate: The metal component is first prepared by cleaning and applying a bonding agent. This step ensures that the surface is free of contaminants and ready for the rubber to adhere effectively.

- Placement in the Mold: The prepared metal substrate is placed into a mold designed to create the desired shape of the final part. The mold is engineered to accommodate both the metal and rubber components.

- Injection of Rubber Material: Rubber material, typically in a molten or semi-molten state, is injected into the mold around the metal substrate. The rubber flows into the mold, filling the cavities and forming a bond with the metal surface.

- Curing: The mold is heated to cure the rubber, solidifying the bond between the metal and rubber components. This curing process ensures that the rubber adheres firmly to the metal, creating a durable, bonded part.

- Final Inspection and Quality Control: After curing, the part is removed from the mold and inspected for quality. Any excess material (flash) is trimmed, and the part undergoes rigorous testing to ensure it meets all specifications.

Learn More About Overmolding

Elastomers

CanRez™ FFKM Perfluoroelastomer

Extreme temperatures & chemicals require extreme solutions! CanRez™ FFKM overmolded bonded metal-to-rubber parts offer extreme reliability where you need it most! Thousands of sizes in stock now!

CanGuard™ RFI & EMI Shielding Materials

CanGuard™ overmolded bonded metal-to-rubber parts have been developed to offer superior sealing solutions with enhanced electromagnetic interference (EMI) shielding and radio frequency interference (RFI) shielding.

Kalrez® FFKM Perfluoroelastomer

Canyon Components offers Kalrez® Perfluoroelastomer (FFKM) overmolded bonded metal-to-rubber parts, O-rings, gaskets, & custom molded parts at competitive prices and with great lead-times.

Parker® overmolded bonded metal-to-rubber parts, O-rings, Parofluor parts, parker FKM Viton

Canyon Components offers Parker Hannifin® overmolded bonded metal-to-rubber parts, O-rings, Gaskets, Perfluoroelastomer (FFKM) parts, & custom molded parts at competitive prices and with great lead-times.

FKM (Viton®, Fluorocarbon)

FKM overmolded bonded metal-to-rubber parts, compounds, O-rings, gaskets, & custom molded parts exhibit excellent mechanical attributes as well as excellent resistance to high temperatures, mineral oil, ozone, fuels, hydraulic fluids, and many other solvents and chemicals.

Aflas® (TFE/P)

TFE/P (Aflas) overmolded bonded metal-to-rubber parts, compounds, O-rings, gaskets, & custom molded parts gives high resistance to steam, hot water, atmospheric wear, and many chemicals. TFE/P compounds provide superior performance in water, steam and virtually all caustic chemicals.

Fluorosilicone (FVMQ)

The mechanical and physical properties of Fluorosilicone overmolded bonded metal-to-rubber parts, O-rings, gaskets, & custom molded parts are very similar to silicone. Fluorosilicone O-rings, gaskets, & custom molded parts offer improved flexibility and strength, better resistance to fuels and mineral oil, but reduced hot air resistance.

Silicone (VMQ, PVMQ)

Silicone overmolded bonded metal-to-rubber parts, seals, O-rings, gaskets, & custom molded parts are excellent for extreme temperatures in static applications. Canyon Components carries a range of silicone materials, and we are happy to custom tailor a seal to meet your application requirements!

EPDM (Ethylene Propylene)

EPDM overmolded bonded metal-to-rubber parts, materials, O-rings, gaskets, & custom molded parts can operate over a wide temperature range, and are compatible with glycol fluids that cause problems for most typical elastomeric seals.

NBR (Nitrile, Buna-N)

Nitrile overmolded bonded metal-to-rubber parts, O-rings, gaskets, & custom molded parts are very oil-resistant, have strong mechanical properties, are resistant to wear, and are relatively inexpensive. These properties make Nitrile the most commonly used general purpose O-ring, gasket, & custom molded part material.

HNBR (Hydrogenated Nitrile)

Hydrogenated Nitrile overmolded bonded metal-to-rubber parts, O-rings, gaskets, & custom molded parts offer higher strength and reduced degradation at high temperatures compared to conventional Nitrile materials. These properties make HNBR materials popular in the oil and gas industry, as well as many applications in the chemical industry.

XNBR (Carboxylated Nitrile)

XNBR overmolded bonded metal-to-rubber parts, O-rings, gaskets, & custom molded parts are similar to Nitrile, but the backbone has been chemically modified with a Carboxylic Acid group. The resulting elastomer is a Nitrile rubber with outstanding abrasion and chemical resistance, superior to that of traditional Nitrile.

Neoprene (CR)

Chloroprene was the first synthetic rubber, and was developed commercially under the name Neoprene®. Chloroprene overmolded bonded metal-to-rubber parts, rubbers, O-rings, gaskets, & custom molded parts contain Chlorine in the polymer to reduce the reactivity to many oxidizing agents, as well as to oil and flame.

Polyurethane (PU, AU)

Polyurethane overmolded bonded metal-to-rubber parts, O-rings, gaskets, & custom molded parts generally have two or three times greater tensile strength and wear resistance than Nitrile and comparable polymers. Polyurethane also provides excellent permeation resistance when compared to most rubbers.

Product Types

Custom Parts

Here at Canyon Components, we make sure to offer our customers any manufacturing technique they desire. Whether your overmolded bonded metal-to-rubber parts, O-rings, gaskets, & custom molded parts be rubber, plastic, or metal, rest assured that Canyon Components can make it!

Gaskets & Custom Cutting

Whether your custom cut parts be rubber, plastic, sponge, composite, or metal, rest assured that Canyon Components can make it! Canyon Components strives to meet all customer service requests. If you need something that isn't listed, feel free to contact a Canyon Components product and application consultant.

Infinite "Giant" Diameter O-Rings

By either Continuous Molding O-rings, or Splice & Vulcanizing O-rings, Canyon can provide mold-less, infinitely large O-rings at competitive prices!

Specialty Compliances

Canyon have materials available for overmolded bonded metal-to-rubber parts, O-rings, gaskets, & custom parts with compliances ranging from USP Class VI <87> & <88> for medical applications, to FDA CFR 21.177.2600 grades A through F for different food types, to the various drinking water specifications like KTW and NSF. Whether it's metal, rubber, or plastic, Canyon can meet your needs!

Metals

Steel

Steel is a strong, durable alloy primarily made from iron and carbon. It's characterized by its high tensile strength and resistance to corrosion and wear. Steel often contains additional elements like chromium, nickel, and manganese to enhance its properties.

Carbon Steel

Carbon steel, a robust alloy of iron and carbon, is distinguished by its impressive tensile strength, hardness, and ability to be magnetized. Predominantly used in construction and manufacturing, it features a silver-gray appearance and excels in durability and wear resistance.

Alloy Steel

Alloy steel is a robust metal composed of iron mixed with various elements like chromium, nickel, molybdenum, and vanadium. This combination enhances properties such as strength, hardness, durability, and corrosion resistance, making it ideal for diverse industrial applications.

Stainless Steel

Stainless steel, an alloy of iron, chromium, and often nickel, is renowned for its corrosion resistance and lustrous appearance. Its durability, easy maintenance, and hygienic qualities make it a popular choice in kitchenware, medical equipment, and architectural structures.

Aluminum

Aluminum, a lightweight, silver-white metal, is known for its remarkable corrosion resistance and high strength-to-weight ratio. It's easily machinable, conducts heat and electricity well, and is widely used in aerospace, transportation, and packaging industries due to its versatility.

Brass

Brass is a versatile alloy primarily composed of copper and zinc, known for its golden-yellow hue. It exhibits excellent malleability, acoustic properties, and resistance to corrosion, making it a popular choice for musical instruments, decorative items, and various fittings.

Bronze

Bronze, a copper-tin alloy, often contains small amounts of other elements like aluminum or nickel. It's known for its hardness, durability, and distinctive reddish-brown color. Widely used in sculpture, coins, and industrial applications, bronze resists corrosion and metal fatigue.

Copper

Copper is a reddish-brown, highly ductile and conductive metal, renowned for its thermal and electrical conductivity. It's naturally antimicrobial and corrosion-resistant, extensively used in electrical wiring, plumbing, coinage, and as a component in various metal alloys.

Iron

Iron is a lustrous, ductile, malleable metal with a silvery-gray appearance. As a fundamental building block of modern industry, it is magnetic, has high melting and boiling points, and forms compounds with various elements, prominently influencing Earth's geology and human technology.

Magnesium Alloy

Magnesium alloy, a lightweight and strong metal, is characterized by its low density, high strength-to-weight ratio, and excellent machinability. It's often used in aerospace, automotive industries, and electronics for its weight-saving benefits and ability to dissipate heat effectively.

Nickel Alloy

Nickel alloy, a blend of nickel and other elements, is known for its exceptional corrosion resistance, heat resistance, and strength. It excels in harsh environments, making it ideal for aerospace, chemical processing, and power generation applications. Its silvery-white appearance adds to its appeal.

Titanium

Titanium is a lightweight, strong metal with a silvery-white appearance, known for its exceptional corrosion resistance and high strength-to-density ratio. Widely used in aerospace, medical implants, and sporting equipment, it forms alloys with elements like aluminum and vanadium.

Tungsten Carbide

Tungsten carbide, a composite of tungsten and carbon, is exceptionally hard and wear-resistant. It has a high melting point and great rigidity, making it ideal for cutting tools, abrasives, and armor-piercing rounds. Its density and strength are comparable to those of diamond.

Zinc Alloy

Zinc alloy is a robust metal combination mainly composed of zinc, often blended with aluminum, copper, and magnesium. It's known for its high strength, good corrosion resistance, and ability to be cast into intricate shapes, commonly used in die-casting and automotive parts.

Bonded Metal-to-Rubber Parts Pros & Cons

Bonded metal-to-rubber parts offer a unique combination of strength, flexibility, and durability, making them ideal for a wide range of demanding applications. The overmolding manufacturing process ensures a strong bond between the metal and rubber components, providing reliable performance in environments where vibration, noise, and corrosion resistance are critical. While there are some challenges associated with the manufacturing process and material compatibility, the benefits of using bonded metal-to-rubber parts often outweigh these considerations, making them a valuable solution for industries such as automotive, aerospace, and industrial machinery. Understanding the features, applications, and potential drawbacks of bonded metal-to-rubber parts will help you make informed decisions to ensure optimal performance in your projects.

Canyon Components strives to meet all customer service requests. Feel free to contact Canyon Components engineering and let our knowledgeable staff help you design the perfect part for your needs.

Pros of Bonded Metal-to-Rubber Parts

Bonded metal-to-rubber parts offer several advantages that make them a preferred choice for many applications:

- Enhanced Durability: The strong bond between metal and rubber ensures that these parts can withstand harsh conditions, including mechanical stress, temperature fluctuations, and chemical exposure.

- Noise and Vibration Reduction: The rubber component effectively dampens vibrations and reduces noise, improving the performance and longevity of the equipment.

- Corrosion Protection: The rubber layer acts as a barrier against moisture and corrosive chemicals, protecting the metal substrate from corrosion and extending the life of the part.

- Customizable: The overmolding process allows for a high degree of customization, enabling the production of parts tailored to specific application requirements.

- Cost-Effective: While the initial tooling and manufacturing costs may be higher, the durability and performance of bonded metal-to-rubber parts often result in lower long-term costs due to reduced maintenance and replacements.

Cons of Bonded Metal-to-Rubber Parts

While bonded metal-to-rubber parts offer many benefits, there are also some potential drawbacks to consider:

- Complex Manufacturing Process: The overmolding process requires precise control and specialized equipment, which can increase production costs and lead times.

- Material Compatibility: The effectiveness of the bond depends on the compatibility of the metal and rubber materials, as well as the quality of the bonding agent used. Incompatible materials can lead to bond failure.

- Limited Temperature Range: While the rubber component provides flexibility and shock absorption, it may not perform well at extremely high or low temperatures, which could limit its use in certain applications.

- Higher Initial Costs: The tooling and setup costs for overmolding can be higher compared to simpler manufacturing processes, making it less cost-effective for small production runs.

Back to Products Hub

Get A Quote Now!